Cement foaming fireproofing insulation board

A technology of fire-proof insulation board and cement foaming, which is applied in the directions of heat preservation, fire prevention, and building components. It can solve the problems of exacerbating energy crisis, consumption of petroleum resources, and short service life. It achieves the best chemical stability, wide application range, and comprehensive The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] To prepare the cement foamed fireproof insulation board of the present invention, the mass percentage of the following raw materials is taken: 600 # 63 kg of cement, 3 kg of sulfoaluminate rapid hardening cement, 2 kg of powdered carbonized rice husk, 2.7 kg of cement foam masterbatch, 3.5 kg of water at a temperature of 35°C to 40°C, 200g of polypropylene fiber and 3.7 kg of hydrogen peroxide Kilogram.

[0029] The sulphoaluminate rapid hardening cement produced by Hebei Tangshan Polar Bear Building Materials Co., Ltd. is used.

[0030] Cement foaming masterbatch is a mixture of calcium hydroxide and calcium carbonate in a ratio of 4:6.

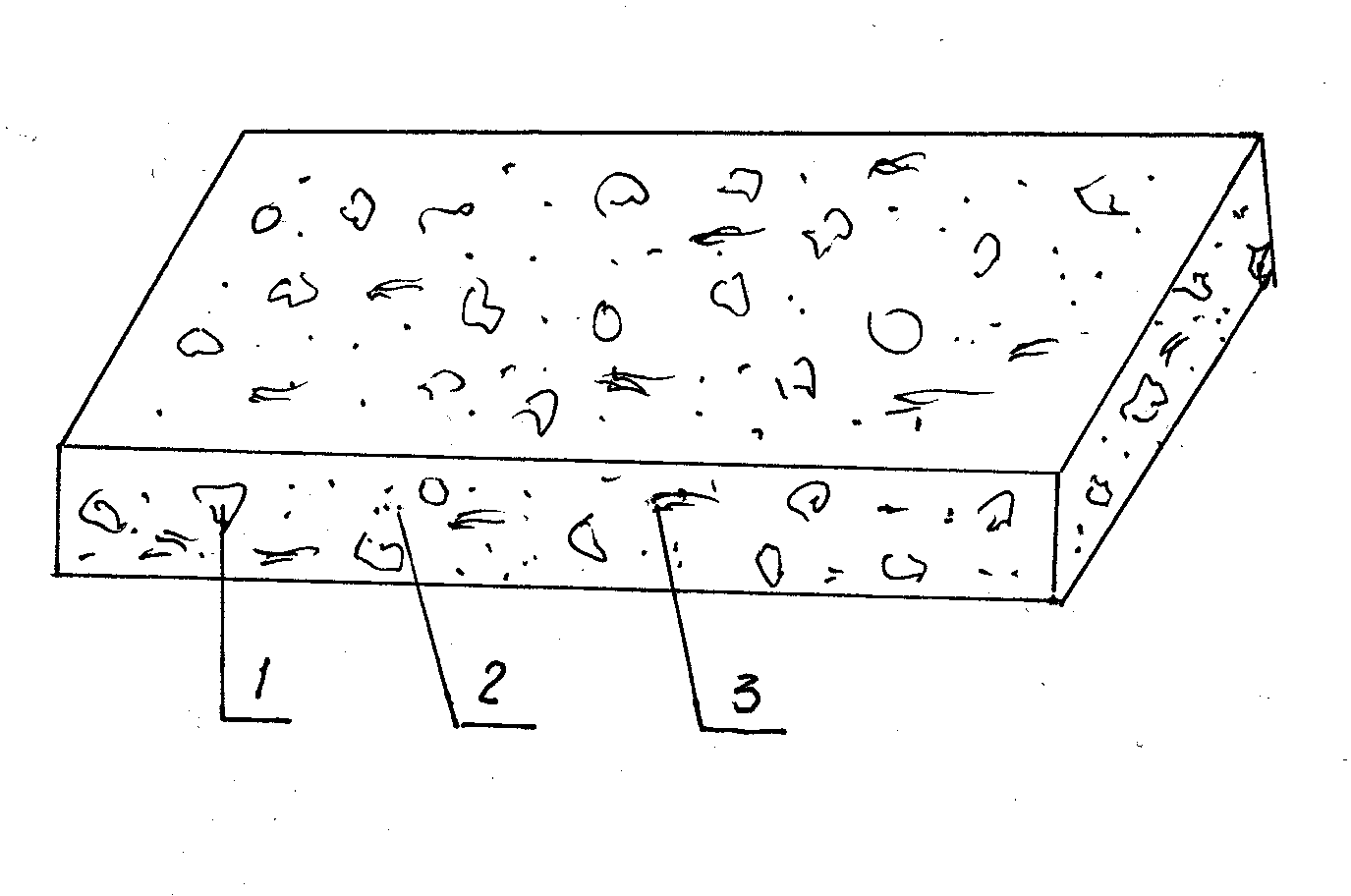

[0031] See figure 1 , in the cement foam fire insulation board, it is composed of: hollow bubble 1, powdery carbonized rice husk 2 and polypropylene fiber filament 3 structure; it is composed of: cement foam fire insulation board, cement foam fire insulation aerated brick board and cement Foam fireproof and heat preservation isolat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com