Biomimetic mineralization preparation method of polyelectrolyte/calcium carbonate composite nanofiltration membrane

A composite nanofiltration membrane and polyelectrolyte technology, which is applied in the field of biomimetic mineralization preparation of polyelectrolyte/calcium carbonate composite nanofiltration membrane, can solve the problems of large particle size of calcium carbonate inorganic particles, inability to control particle size, and lack of flexibility. , to achieve good application effect, good biological functionality, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

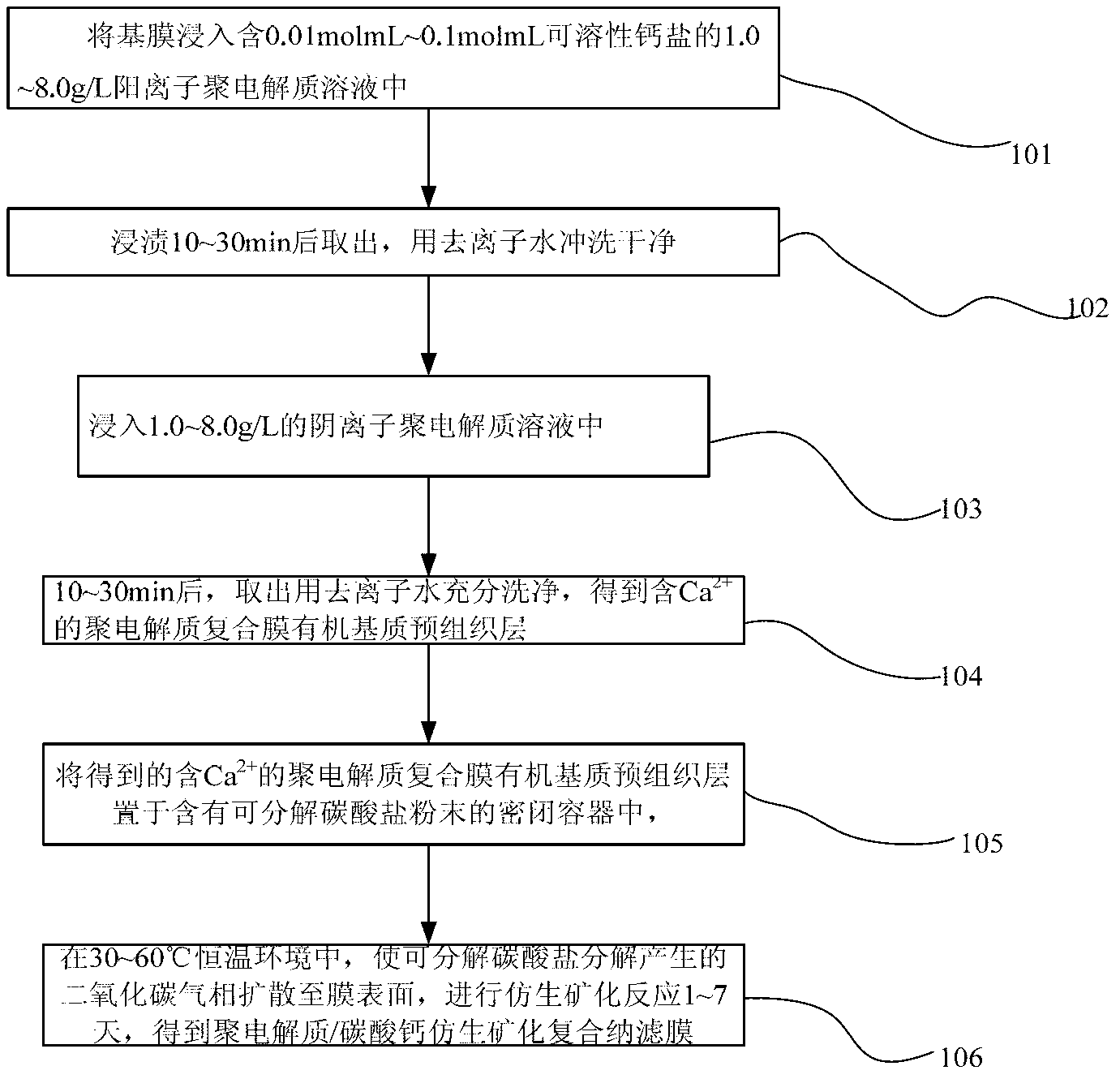

[0025] A biomimetic mineralization preparation method of polyelectrolyte / calcium carbonate composite nanofiltration membrane, such as figure 1 shown, including the following steps:

[0026] Step 101: immerse the base film in a 1.0-8.0 g / L cationic polyelectrolyte solution containing 0.01 mol / mL-0.1 mol / mL soluble calcium salt;

[0027] Step 102: After 10-30 minutes, rinse with deionized water;

[0028] Step 103: immerse in 1.0-8.0 g / L anionic polyelectrolyte solution;

[0029] Step 104: After 10-30 minutes, take it out and wash it thoroughly with deionized water to obtain Ca-containing 2+ Polyelectrolyte composite membrane organic matrix pre-organized layer;

[0030] Step 105: placing the obtained polyelectrolyte composite membrane organic matrix pre-organized layer in an airtight container containing decomposable carbonate powder;

[0031] Step 106: In a constant temperature environment of 30-60°C, the gas phase diffusion of carbon dioxide produced by the decomposition of...

Embodiment 2

[0034] A preparation method for biomimetic mineralization of a polyelectrolyte / calcium carbonate composite nanofiltration membrane, comprising the steps of:

[0035] Step 100: using a polyacrylonitrile ultrafiltration membrane with a molecular weight cut-off of less than 100,000 as the base membrane, treating the base membrane with 0.5 mol / L sodium hydroxide solution for 2 hours, and then washing with deionized water until neutral;

[0036] Step 101: immerse the polyacrylonitrile-based membrane treated in step 100 in 8.0 g / L PEI polyelectrolyte solution containing 0.1 mol / mL calcium acetate;

[0037] Step 102: After 10 minutes, rinse with deionized water;

[0038]Step 103: immerse in 8.0g / L PSS polyelectrolyte solution again;

[0039] Step 104: Take it out after 10 minutes, and wash it thoroughly with deionized water. Repeat the above operation once to obtain the polyelectrolyte composite membrane Ca 2+ pre-organization layer;

[0040] Step 105: the polyelectrolyte composi...

Embodiment 3

[0044] This embodiment is roughly the same as Embodiment 2, except that the following steps are added between step 100 and step 101, specifically as follows:

[0045] Immerse the polyacrylonitrile-based membrane treated in step 100 in 8.0g / L polyethyleneimine (PEI) polyelectrolyte solution, take it out after immersion for 10min, and wash it fully with deionized water; then place it in 8.0g / L polyelectrolyte solution Sodium styrene sulfonate (PSS) polyelectrolyte solution, take it out after 10min, fully wash with water, dry and set aside to obtain polyelectrolyte composite membrane;

[0046] The calcium carbonate inorganic matter in the polyelectrolyte / calcium carbonate composite film obtained by this method has a structure closer to that of the inorganic matter in living organisms (such as shells), has better biological functionality, and has a uniform structure and stable performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com