Orthodontic highly-transparent ceramic bracket and making method thereof

A technology of transparent ceramics and brackets, applied in the direction of brackets, etc., to achieve the effect of lowering sintering temperature, easy operation and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

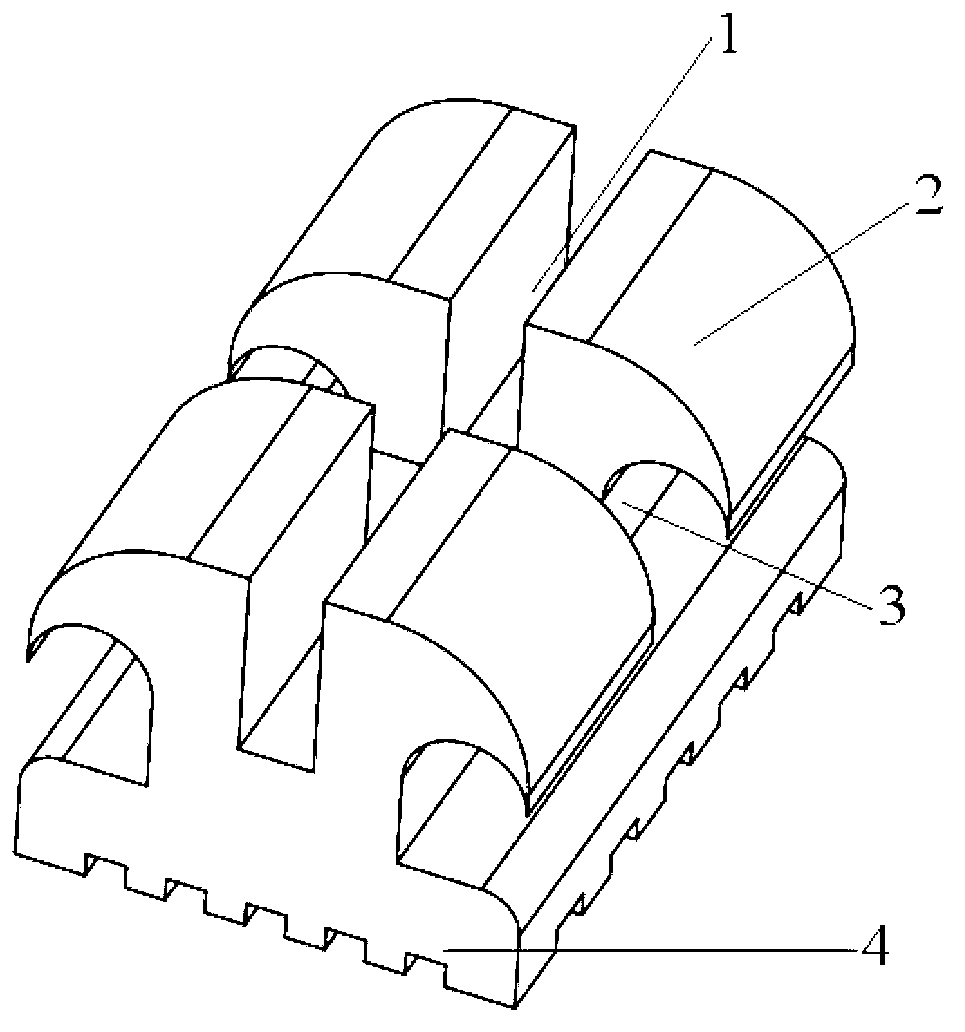

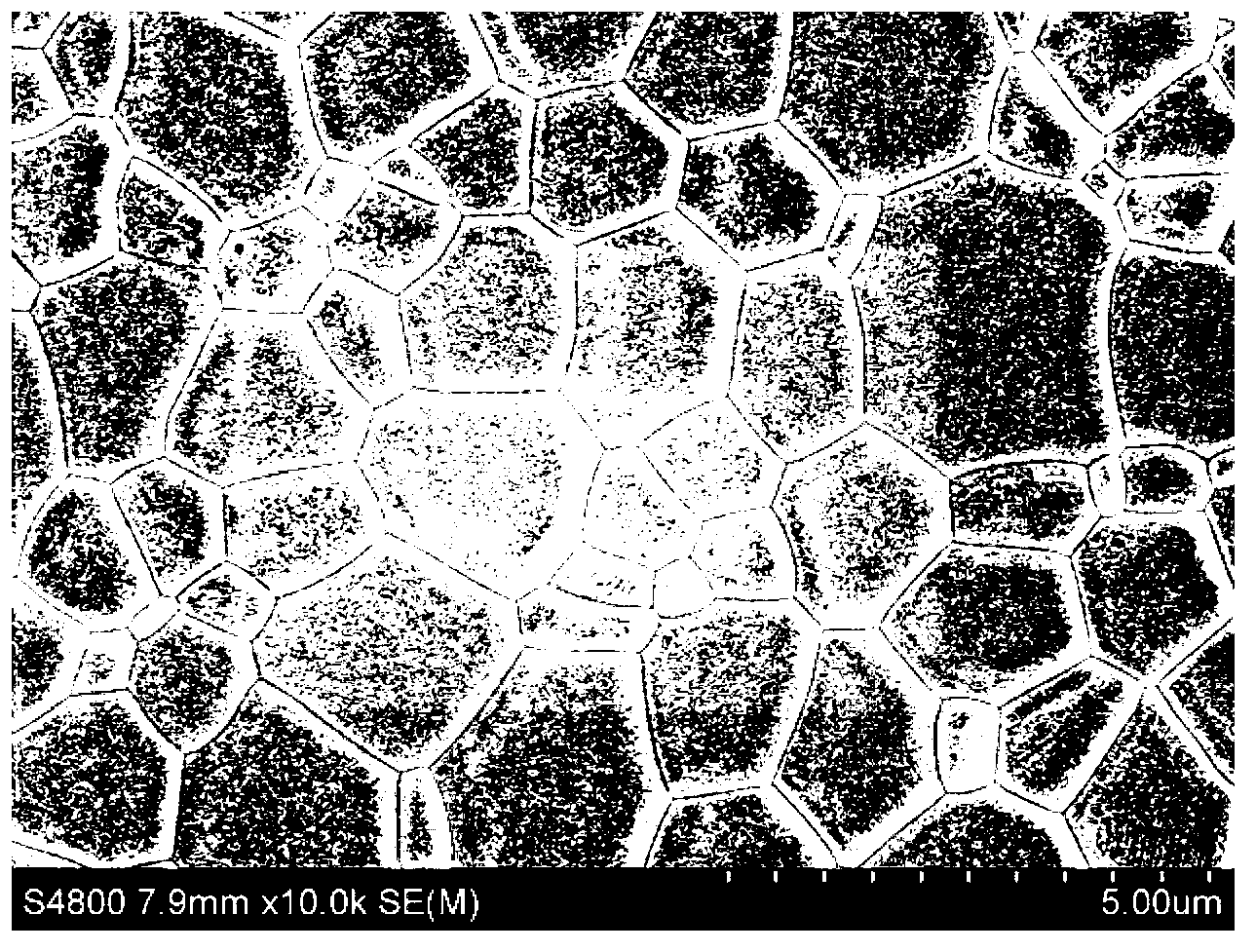

[0030] In the present embodiment, the process steps of preparing the highly transparent ceramic brackets for orthodontics are as follows:

[0031] (1) Preparation of yttrium aluminum garnet (YAG) transparent ceramic powder

[0032] With purity ≥ 99.0% Y (NO 3 ) 3 and NH with purity ≥99.5% 4 Al(SO 4 ) 2 ?12H 2 O is a raw material, and the Y(NO 3 ) 3 with NH 4 Al(SO 4 ) 2 ?12H 2 The molar ratio of O is 0.6:1, with NH 4 HCO 3 As a precipitating agent, the NH 4 HCO 3 with NH 4 Al(SO 4 ) 2 ?12H 2 The molar ratio of O is 1:0.1; Y(NO 3 ) 3 and NH 4 Al(SO 4 ) 2 ?12H 2 O was dissolved in deionized water and formulated as Y 3+ A mixed salt solution with a concentration of 0.1mol / L; the NH measured in the above molar ratio 4 HCO 3 Dissolved in deionized water, formulated as NH 4 HCO 3Precipitant solution with a concentration of 0.4mol / L; at normal pressure and 18°C, drop the prepared mixed salt solution into the prepared precipitant solution at a rate of 220 ...

Embodiment 2

[0043] In the present embodiment, the process steps of preparing the highly transparent ceramic brackets for orthodontics are as follows:

[0044] (1) Preparation of yttrium aluminum garnet (YAG) transparent ceramic powder

[0045] The difference between this preparation method and the preparation method of step (1) in Example 1 is that the YAG precursor is fired at 1100°C for 4 hours, and the average grain size of the prepared yttrium aluminum garnet transparent ceramic powder is is 50 nm.

[0046] (2) Preparation of slurry

[0047] The raw materials are yttrium aluminum garnet transparent ceramic powder with a purity ≥99.0% prepared in step (1), composite sintering aids, polyacrylic acid and deionized water, and the composite sintering aids are made of SiO 2 and MgO composition, SiO 2 The weight ratio to MgO is 4:1, the composite sintering aid is 0.28% of the weight of the yttrium aluminum garnet transparent ceramic powder, polyacrylic acid is 3% of the weight of the yttr...

Embodiment 3

[0056] In the present embodiment, the process steps of preparing the highly transparent ceramic brackets for orthodontics are as follows:

[0057] (1) Preparation of magnesium aluminum spinel (MgAl 2 o 4 ) transparent ceramic powder

[0058] MgSO with purity ≥99.0% 4 ?7H 2 O and NH with purity ≥99.5% 4 Al(SO 4 ) 2 ?12H 2 O is the raw material, the MgSO 4 ?7H 2 O and NH 4 Al(SO 4 ) 2 ?12H 2 The proportion of O is weighed according to the molar ratio of Mg and Al being 1:2. The weighed MgSO 4 ?7H 2 O and NH 4 Al(SO 4 ) 2 ?12H 2 O was put into a quartz cup, added deionized water and stirred to form a mixed solution (the amount of deionized water was submerged over MgSO 4 ?7H 2 O and NH 4 Al(SO 4 ) 2 ?12H 2 O can be), the mixed solution was placed in a muffle furnace, heated to 1100 °C at a rate of 10 °C / min and roasted for 4 hours, and then naturally cooled to room temperature to obtain white and fluffy MgAl 2 o 4 The powder is ground and sieved with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com