Marinated mushroom making method

A technology of braised mushrooms and a production method, which are applied in the fields of food microorganism fermentation and food processing, can solve the problems of insufficient development and utilization of mushroom stems, high degree of fibrosis of mushroom stems, and little research on mushrooms, and the like. The effect of easy industrial production, improved quality stability and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with specific examples, but the present invention is not limited to these examples.

[0023] Embodiments 1-8 are all based on the parts by weight of the raw materials described in Table 1, and prepare stewed shiitake mushrooms according to the following steps:

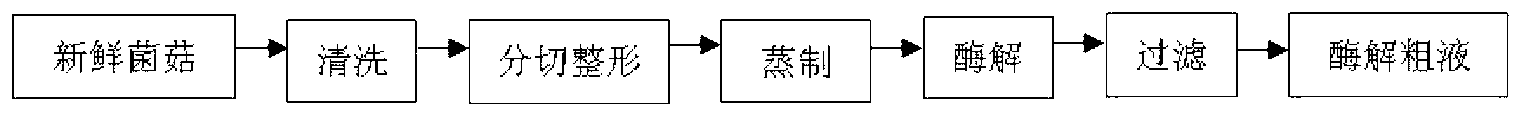

[0024] Step 1: Cleaning, cutting and shaping the fresh shiitake mushrooms, steaming and curing them to obtain the matured raw materials;

[0025] Step 2: Prepare the prepared aging raw material and water according to the recipe amount, and add various enzymes in the recipe amount during the preparation process, and carry out the enzymolysis reaction at 30-55°C for 1-24 hours to obtain the enzymolysis crude liquid;

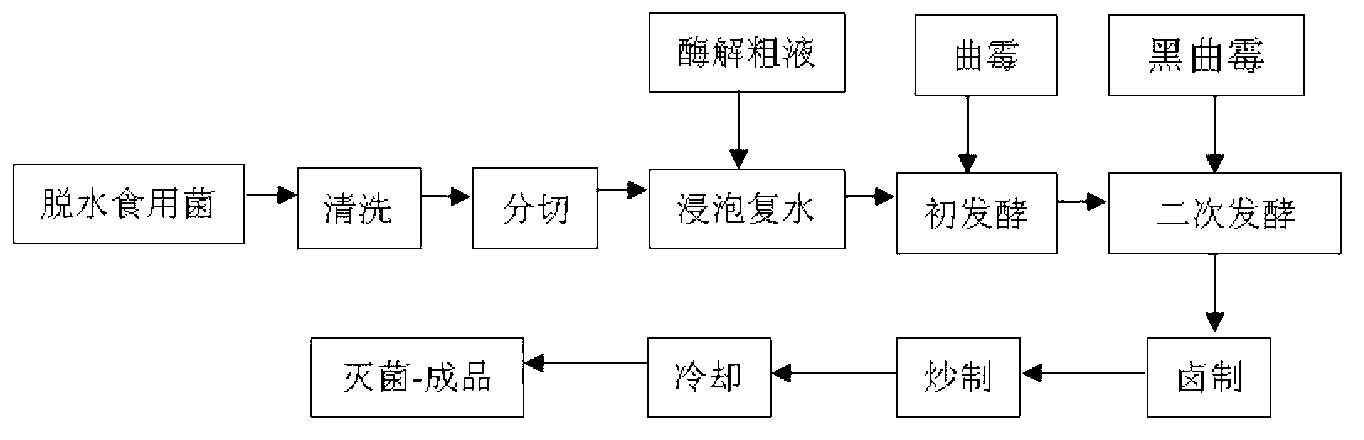

[0026] Step 3: first use the enzymolysis crude liquid to rehydrate the dehydrated shiitake mushrooms at 30-55°C, and the rehydration time is 1-6h; when the rehydration rate reaches 200-300%, divide the rehydrated shiitake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com