Method for passivating amorphous silicon and polycrystalline silicon film interfaces and manufacturing single junction polycrystalline silicon amorphous silicon (SPA) structure heterojunction with intrinsic thin-layer (HIT) cell

A technology of polysilicon thin film and amorphous silicon, which is applied in the field of solar cells, can solve the problem of many defect states, achieve the effects of reducing recombination, reducing interface state density, and improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

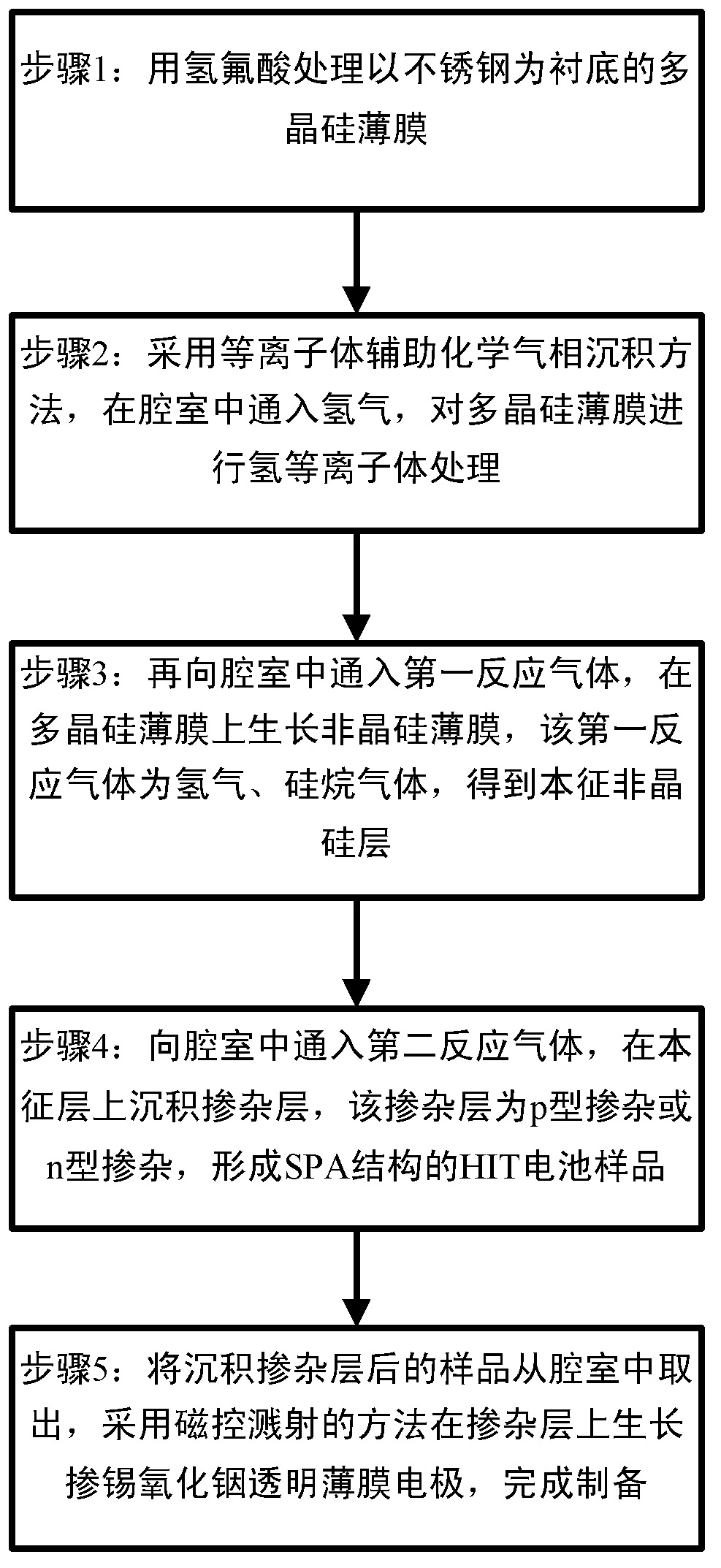

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0029] The passivation method of solar cell amorphous silicon and polysilicon film interface provided by the present invention is to adopt plasma enhanced chemical vapor deposition (Plasma Enhanced Chemical Vapor Deposition, PECVD), under the situation of passing into chamber hydrogen, to solar cell The interface between amorphous silicon and polysilicon film is passivated. Wherein, the specific process of passivating the interface between the amorphous silicon and the polysilicon film of the solar cell is as follows: the polysilicon film sample to be treated is placed in a plasma-enhanced chemical vapor deposition device with a radio frequency of 13.56 MHz, and the Put hydrogen gas into the equipment, the flow rate of hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com