Long-service-life LED energy-saving lamp

An energy-saving lamp and long-life technology, which is applied in the direction of lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems that the service life of LED lamps is not as good as the theoretical value, increase the cost of using LED energy-saving lamps, and prevent horizontal convection of air. Achieve the effect of good heat dissipation, simple structure and small thermal shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

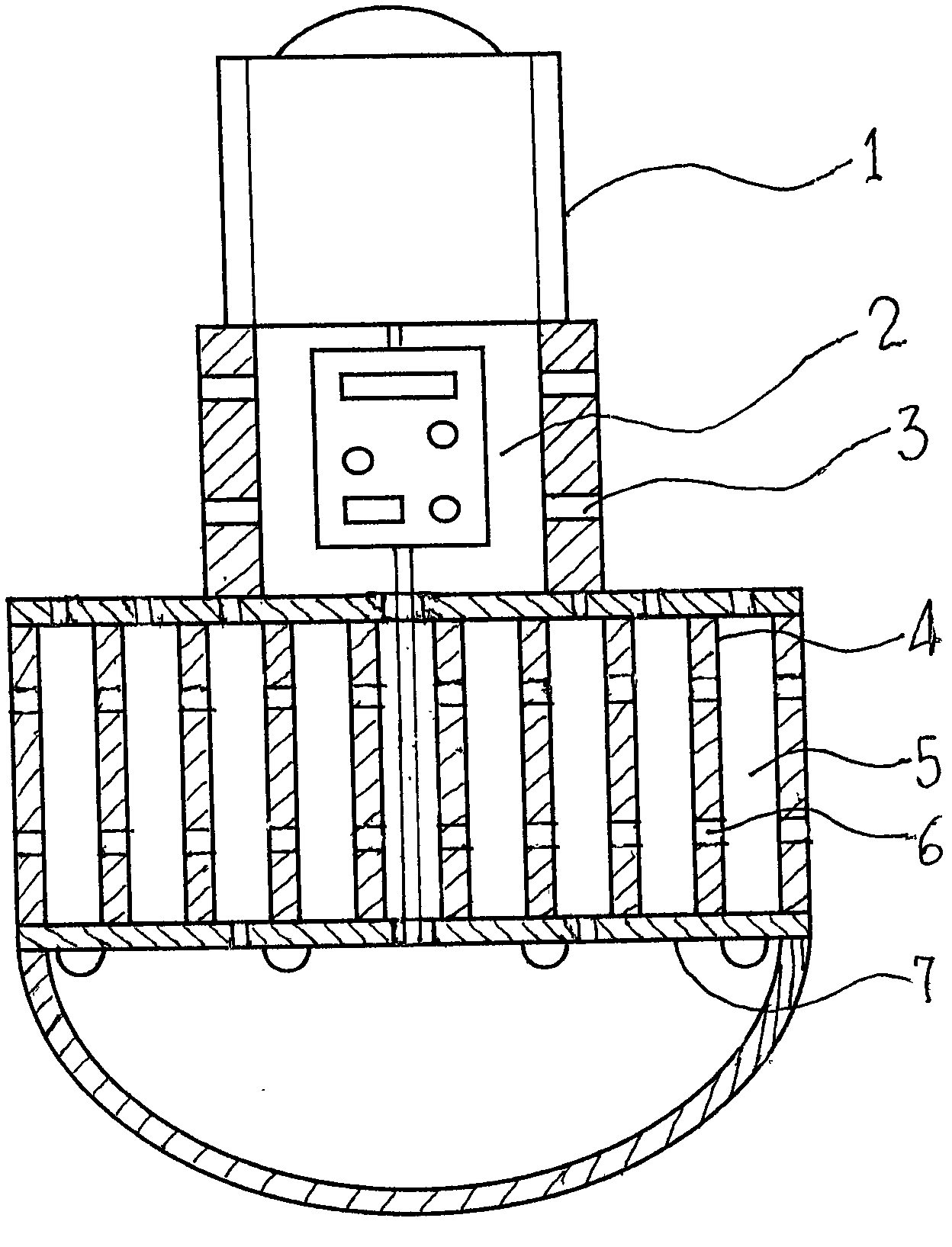

[0015] As shown in the figure, the LED long-life energy-saving lamp of the present invention includes a lamp cap assembly 1, an LED core board 7, and a heat dissipation mechanism connected to the lamp cap assembly 1 and the LED core board 7 respectively, and the feature is that the heat dissipation mechanism has a heat sink 4 1. There are heat dissipation passages 5 penetrating from one side to the other between each of the heat dissipation fins 4, and the whole heat dissipation mechanism has heat dissipation passages 5 penetrating from one side to the other side, and the heat dissipation fins 4 have heat dissipation ports 6. The lamp head assembly has a drive power supply assembly cavity 2, which is arranged at the lower part of the lamp cap assembly 1, the lower end of the drive power supply assembly cavity is connected to the heat dissipation mechanism, and the cavity wall of the drive power supply assembly cavity 2 It has cavity cooling vent 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com