Hydrolysis hydrogen production device with internal integrated feeding tank and layered heat conduction and drying architecture

A technology of hydrogen production device and material pool, which is applied in the directions of hydrogen production and energy input, can solve the problems of reducing energy utilization rate, short response time, difficult to carry, etc., to achieve full utilization, improve utilization efficiency, and increase airflow passages Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

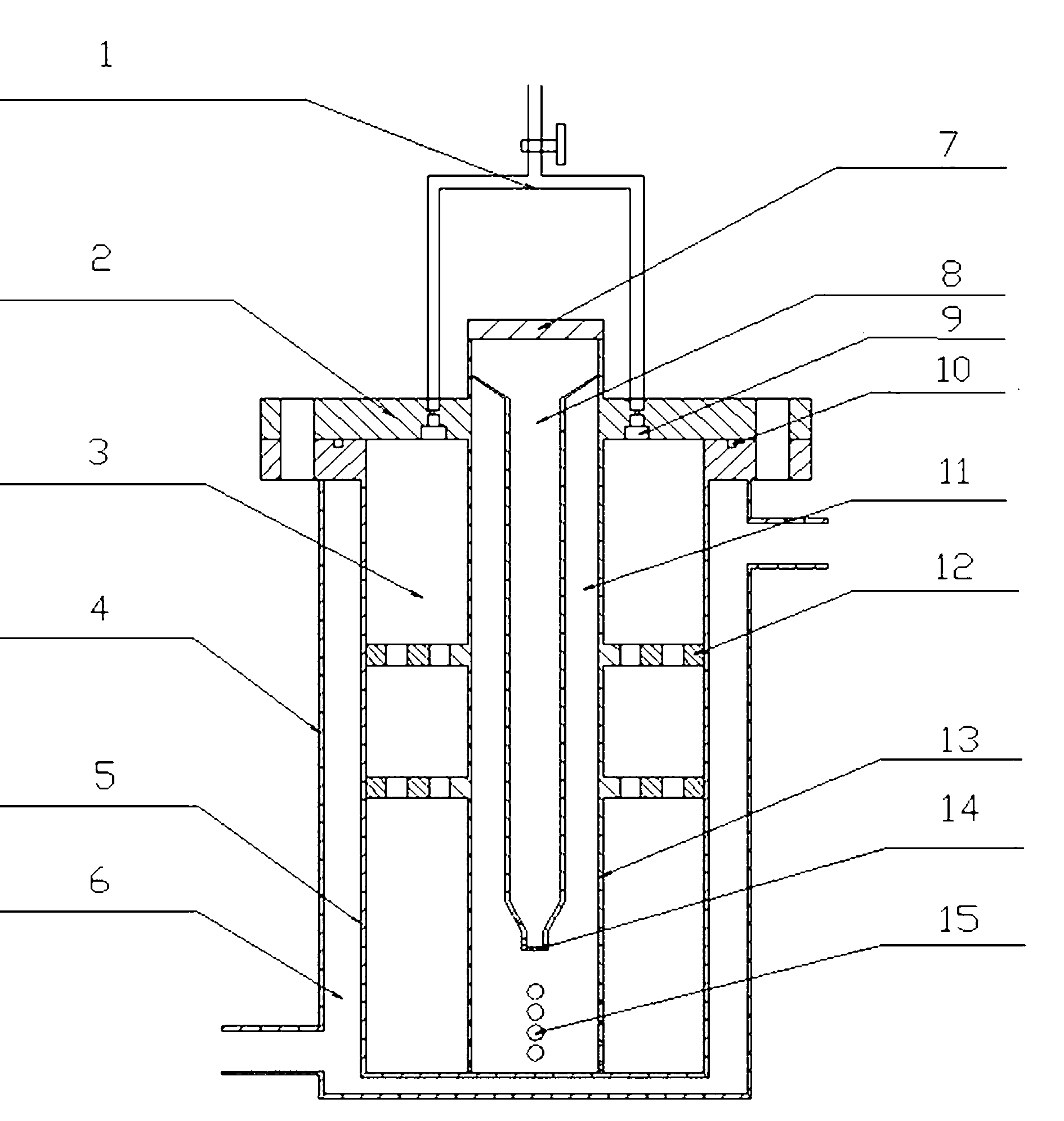

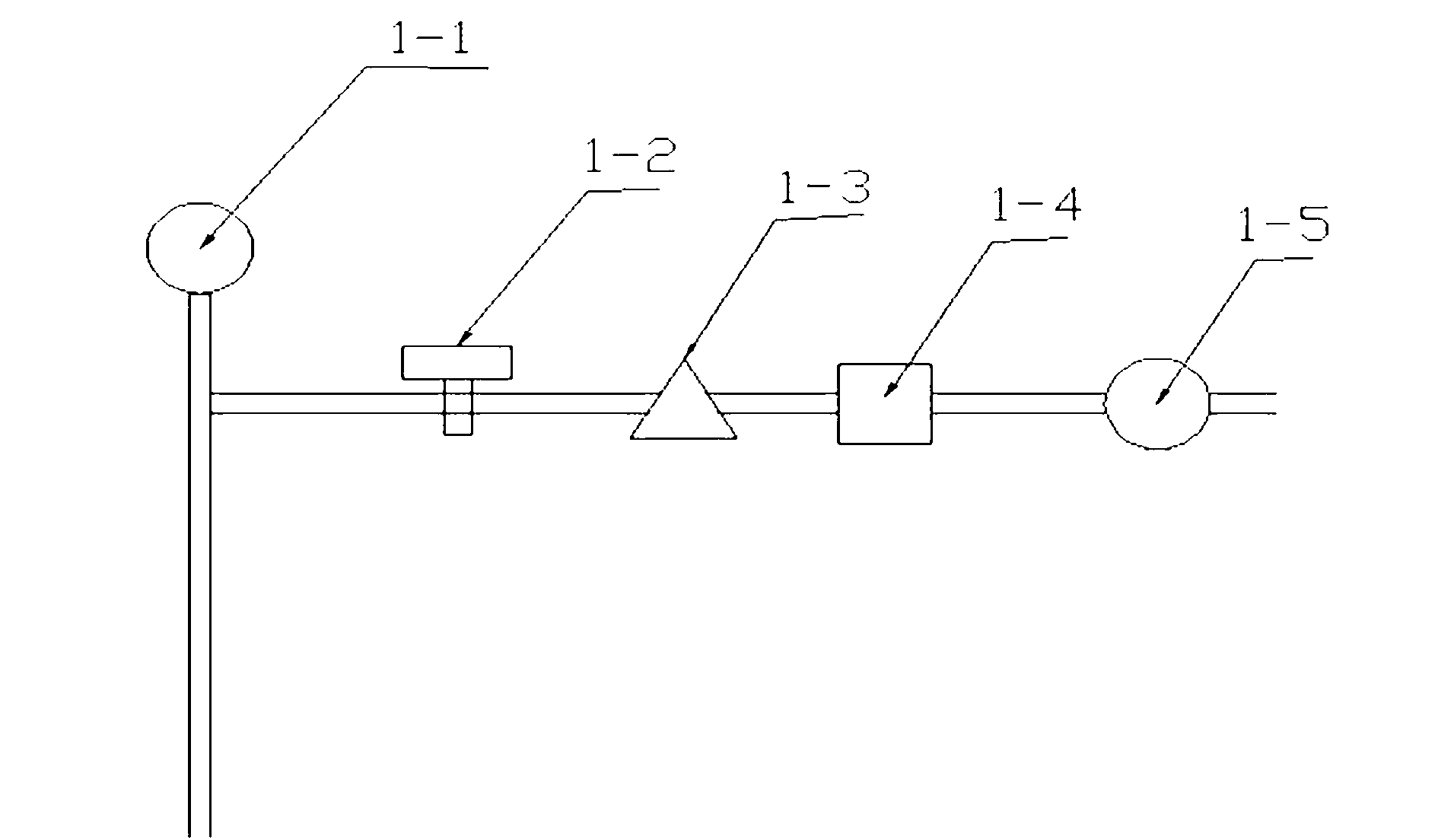

[0022] attached figure 1 It is an overall cross-sectional view of the solid-state hydrogen storage device in this embodiment, including the peripheral hydrogen discharge gas circuit system 1, the top sealing cover 2, the gas drying chamber 3, the outer shell 4, the inner tank 5 inside the outer shell 4, the outer shell 4 and the inner tank The external circulating water system 6 between 5, the sealing plug 7 on the feeding tank 8, the feeding tank 8, the air outlet valve 9, the groove 10 of the sealing gasket, the gas buffer chamber 11, and the heat conduction drying structure 12 reasonably arranged in the inner tank 5 , a cylindrical sleeve 13, an electronically controlled one-way valve 14, a through hole 15 on the cylindrical sleeve 13.

[0023] The internal structure is as attached Figure 5 shown. It includes a cylindrical sleeve, a heat conduction drying tray, a top sealing cover and an internal feeding pool, wherein the heat conducting drying tray and the top sealing c...

Embodiment 2

[0028] The overall connection of this embodiment is the same as that of Embodiment 1, except that the hydrolyzed powder material contains a variety of different components, which can affect the rate and amount of hydrogen production.

Embodiment 3

[0030] The overall link of this embodiment is the same as that of Embodiment 1, except that the hydrogen production device adds multiple hydrogen discharge branches, which can be used by multiple fuel cells at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com