Method for preparing modified polyether sulfone hollow fiber membrane

A fiber membrane, polyethersulfone technology, applied in the field of polymer materials, can solve the problems of membrane strength damage, shedding, membrane pollution, etc., and achieve the effects of improving hygroscopic performance, reducing surface tension, and lasting hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

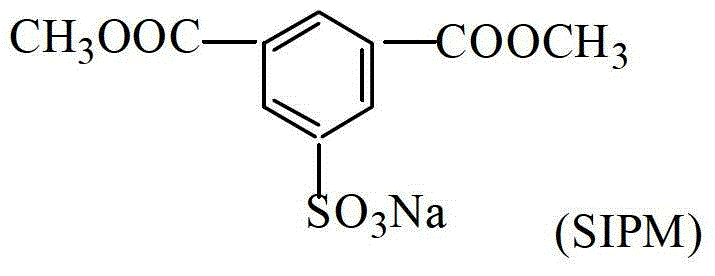

[0025] Preparation of sulfonated polyester: Add 5-sulfonate sodium isophthalate (SIPE), terephthalic acid (TPA), isophthalic acid (IPA), polyethylene glycol during polyester synthesis (PEG) was used as a modifying monomer to synthesize sulfonated polyesters. The third monomer commonly used in sulfonated polyesters is sodium dimethyl sulfoisophthalate (SIPM). Has the following molecular formula:

[0026]

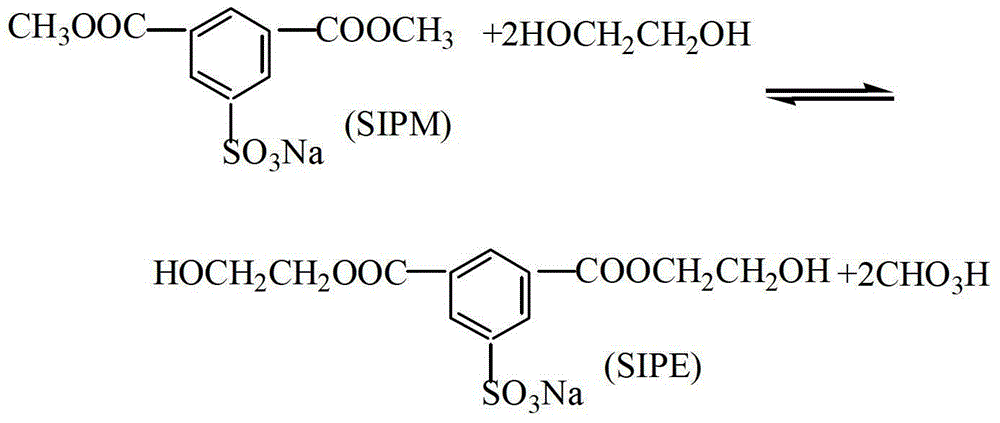

[0027] First carry out transesterification with ethylene glycol, make ethylene glycol sulfonate isophthalate solution, its reaction is as follows:

[0028]

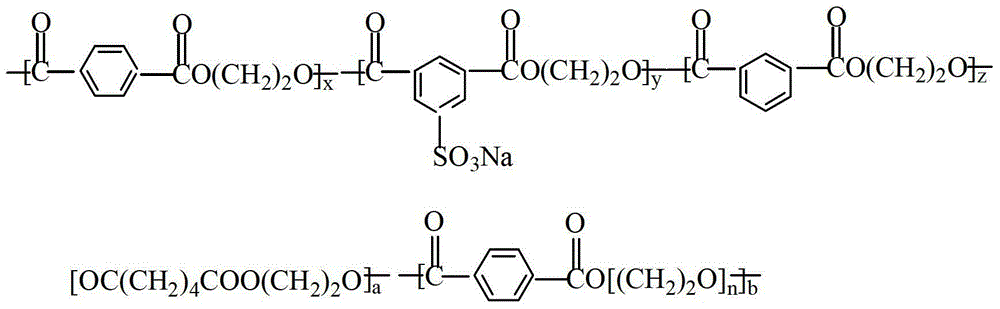

[0029] Then through esterification and polycondensation reaction to synthesize sulfonated polyester, the chemical structure formula is as follows.

[0030]

[0031] (where x, y, z, n, a, b represent the degree of polymerization x: 100~120; y: 5~30; z: 5~20; a: 0~5; b: 0~5; n: 5 ~10)

[0032] Due to — SO 3 Na is a polar hydrophilic group, and the hydrophilicity of the polymer increases with the increase of SIP...

Embodiment 1

[0036] The formula of sulfonated polyester raw material is:

[0037]

[0038] The molar ratio of ethylene glycol (EG) to the total amount of all the above acids is controlled at 1.6:1; the esterification temperature is controlled at 220-240°C, and the esterification pressure is controlled at 0.1-0.3MP. After the end of the esterification process, the system pressure was gradually reduced for 30 minutes under normal pressure to carry out the polycondensation reaction. The polycondensation temperature is controlled at 240-280°C. The polycondensation is subject to the stirring power reaching a predetermined value. This stirring power corresponds to a viscosity-average molecular weight of sulfonated polyester of 18,000. Medium cast belt, pelletized.

[0039] Mix polyethersulfone and sulfonated polyester mechanically at a ratio of 95:5wt%, as a solute, N,N-dimethylacetamide (DMAc) as a solvent, and dissolve the solute and solvent at a ratio of 15:85wt% , The dissolution proces...

Embodiment 2

[0043] The formula of sulfonated polyester raw material is:

[0044]

[0045] The molar ratio of ethylene glycol (EG) to the total amount of all the above acids is controlled at 1.6:1; the esterification temperature is controlled at 220-240°C, and the esterification pressure is controlled at 0.1-0.3MP. After the end of the esterification process, the system pressure was gradually reduced for 30 minutes under normal pressure to carry out the polycondensation reaction. The polycondensation temperature is controlled at 240-280°C, and the polycondensation is subject to the stirring power reaching a predetermined value. As the addition of SIPE increases, the apparent viscosity of the melt increases. This stirring power corresponds to a viscosity-average molecular weight of sulfonated polyester of about 15,000. After the polycondensation is completed, fill the vacuum with nitrogen and press out the polymer, and cast it in cold water. , Diced.

[0046] Mix polyethersulfone and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com