Water turbine with multiple vanes

A water turbine and blade technology, which is applied in the fields of water turbine design and manufacture and mechanical design and manufacture, can solve problems such as complex adjustment, and achieve the effects of reducing cost, low production cost and simple manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is further described by the following examples. This example is only used to further illustrate the present invention, but it cannot be interpreted as limiting the protection scope of the present invention. Essential improvements and adjustments belong to the protection scope of the present invention.

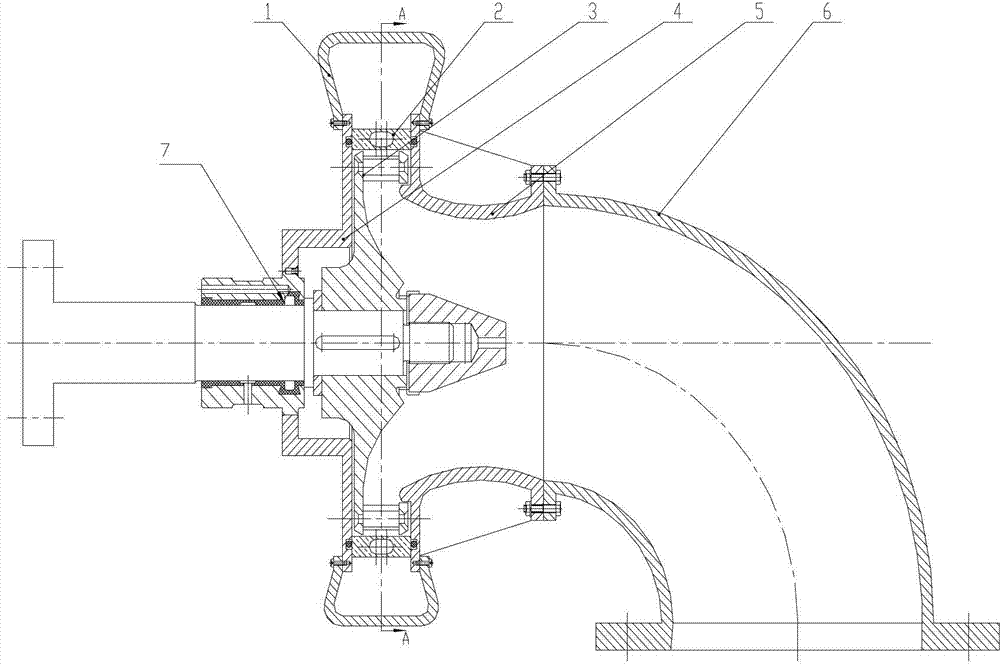

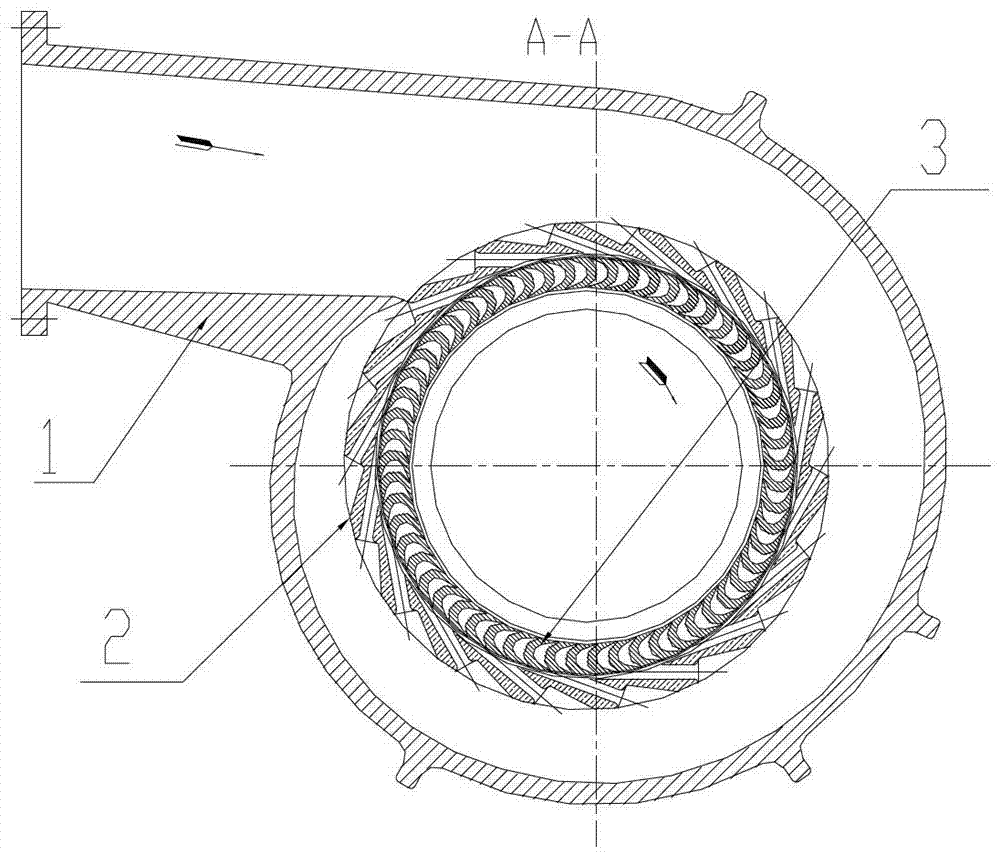

[0037] combine Figure 1 to Figure 12 .

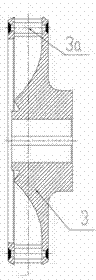

[0038] A multi-blade water turbine, including a volute 1, a runner 3, a support cover 4, a bearing 7, a bottom ring 5 and a discharge pipe 6, which form the turbine, and nozzles are arranged in the spiral flow channel of the volute 1 and the radial periphery of the runner 3 Ring 2, the nozzle ring 2 has nozzle holes 2a arranged at uniform intervals to drive the runner 3 by the spray liquid flow.

[0039] There are vanes 3a arranged at uniform intervals on the circumference of the runner 3, and an arc-shaped flow channel 3b matching the spraying liquid flow of the spray hole 2a is formed between the vanes 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com