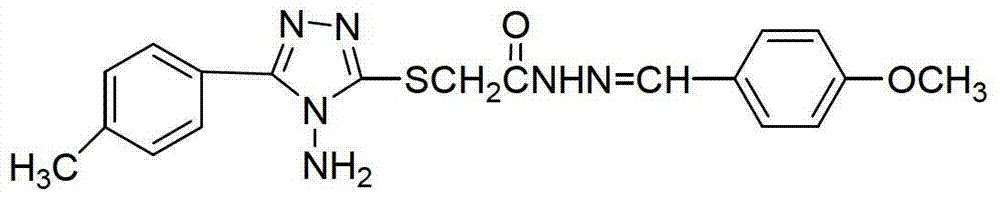

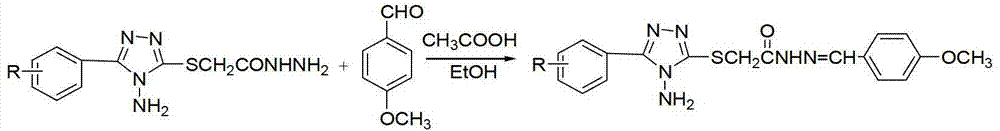

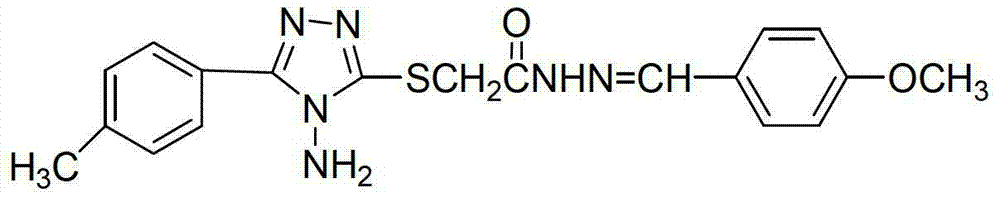

Application of triazole compound containing anisic aldehyde as efficient corrosion inhibitor

A technology of anisaldehyde and compounds, applied in the application field of high-efficiency corrosion inhibitors, can solve the problems of scarcity of corrosion inhibitors, copper corrosion damage, poor activity, etc., and achieve excellent corrosion inhibition performance, low cost, and good durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The experimental material is red copper (99.999%). The compound of formula 1 is formulated as a corrosion inhibitor. The medium is 3.5% sodium chloride solution. The red copper product is immersed in the medium with the corrosion inhibitor at a temperature of 25°C and a pH of 7.5. The amount of medium used is 100L, the amount of the compound of formula 1 in the medium is 0.5g, the temperature is 25°C, pH=6.5, and the immersion time is 14 days.

[0029] Corrosion inhibitor is: the compound of formula one is dissolved in cyclohexane, and it and cyclohexane (C 4 h 12 ) in a weight ratio of 1:10, then ultrasonically disperse the mixed solution for 20 minutes at room temperature with an ultrasonic disperser to make it completely dissolved; then, add the fully dissolved solution to the OP-10 emulsifier (C 34 h 62 o 11 ) (Tianjin Damao Chemical Instrument Supply Station), the amount of OP-10 emulsifier added is the same as that of cyclohexane (C 4 h 12 ) in a weight ratio...

Embodiment 2

[0032] The experimental material is red copper (99.999%). The compound of formula 1 is formulated as a corrosion inhibitor. The medium is 3.5% sodium chloride solution. The red copper product is immersed in the medium with the corrosion inhibitor at a temperature of 25°C and a pH of 7.5. The amount of medium used is 100L, the amount of the compound of formula 1 in the medium is 1.0g, the temperature is 25°C, pH=6.5, and the immersion time is 14 days.

[0033] Corrosion inhibitor is: the compound of formula one is dissolved in cyclohexane, and it and cyclohexane (C 4 h 12 ) in a weight ratio of 1:10, then ultrasonically disperse the mixed solution for 20 minutes at room temperature with an ultrasonic disperser to make it completely dissolved; then, add the fully dissolved solution to the OP-10 emulsifier (C 34 h 62 o 11 ) (Tianjin Damao Chemical Instrument Supply Station), the amount of OP-10 emulsifier added is the same as that of cyclohexane (C 4 h 12 ) in a weight ratio...

Embodiment 3

[0036] The experimental material is red copper (99.999%). The compound of formula 1 is formulated as a corrosion inhibitor. The medium is 3.5% sodium chloride solution. The red copper product is immersed in the medium with the corrosion inhibitor at a temperature of 25°C and a pH of 7.5. The amount of medium used is 100L, the amount of the compound of formula 1 in the medium is 2.0g, the temperature is 25°C, pH=6.5, and the immersion time is 14 days.

[0037] Corrosion inhibitor is: the compound of formula one is dissolved in cyclohexane, and it and cyclohexane (C 4h 12 ) in a weight ratio of 1:10, then ultrasonically disperse the mixed solution for 20 minutes at room temperature with an ultrasonic disperser to make it completely dissolved; then, add the fully dissolved solution to the OP-10 emulsifier (C 34 h 62 o 11 ) (Tianjin Damao Chemical Instrument Supply Station), the amount of OP-10 emulsifier added is the same as that of cyclohexane (C 4 h 12 ) in a weight ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com