Strain capable of producing carboxyethylhydantoinase and application thereof

A technology for the production of carboxyethyl hydantoin and bacteria, applied in the fields of bioengineering and enzyme engineering, can solve the problem that carboxyethyl hydantoin enzyme is blank, and achieve the effect of simple fermentation method and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: This experiment illustrates the screening process of natural strains producing carboxyethylhydantoinase.

[0024] Medium:

[0025] A. Broth medium (g / L): beef extract 3, peptone 10, NaCl5, agar 20, pH=7.2

[0026] B. Enrichment medium (g / L): carboxyethyl hydantoin 5, glucose 3, peptone 3, potassium dihydrogen phosphate 5, magnesium sulfate 0.5, ferrous sulfate 0.055, manganese sulfate 0.0045, pH7.0

[0027] C. Screening medium (g / L): add 20g L to the enrichment medium -1 agar powder

[0028] D. Seed medium (g / L): glucose 15, peptone 15, sodium chloride 3, yeast extract 5, potassium dihydrogen phosphate 2,

[0029] Magnesium sulfate 0.25, pH=7.0-7.2

[0030] E. Fermentation medium (g / L): glucose 10, peptone 10, yeast extract 10, sodium chloride 3, potassium dihydrogen phosphate 2, magnesium sulfate 0.25, cobalt chloride 0.05, carboxyethylhydantoin 2, pH= 7.0

[0031] All media were prepared with deionized water, 0.1MPa, sterilized at 121°C for 15 minutes...

Embodiment 2

[0036] Example 2: This experiment illustrates the identification of the biological properties of the carboxyethylhydantoinase-producing strain CW221.

[0037] Biological properties of carboxyethylhydantoinase-producing bacteria CW221: under high-power microscope observation, the cells are mainly oval, short rod-shaped, and the aspect ratio is about 2-3. There are also approximately spherical cells, and the cells are arranged irregularly. Exist alone, no clusters or clusters of cells exist. Gram-negative bacteria; the colonies grown on solid medium plates for 24 hours are round, with a diameter of about 1mm, smooth, milky white, opaque, with uneven edges and a slight protrusion in the middle; cultured on a slant, the colonies grow along the lines , the edge is not smooth and has small thorns; when cultured in shake flasks, the culture medium is milky white and opaque. Physiological and biochemical characteristics show that the bacteria is obligate aerobic, can not use glucose ...

Embodiment 3

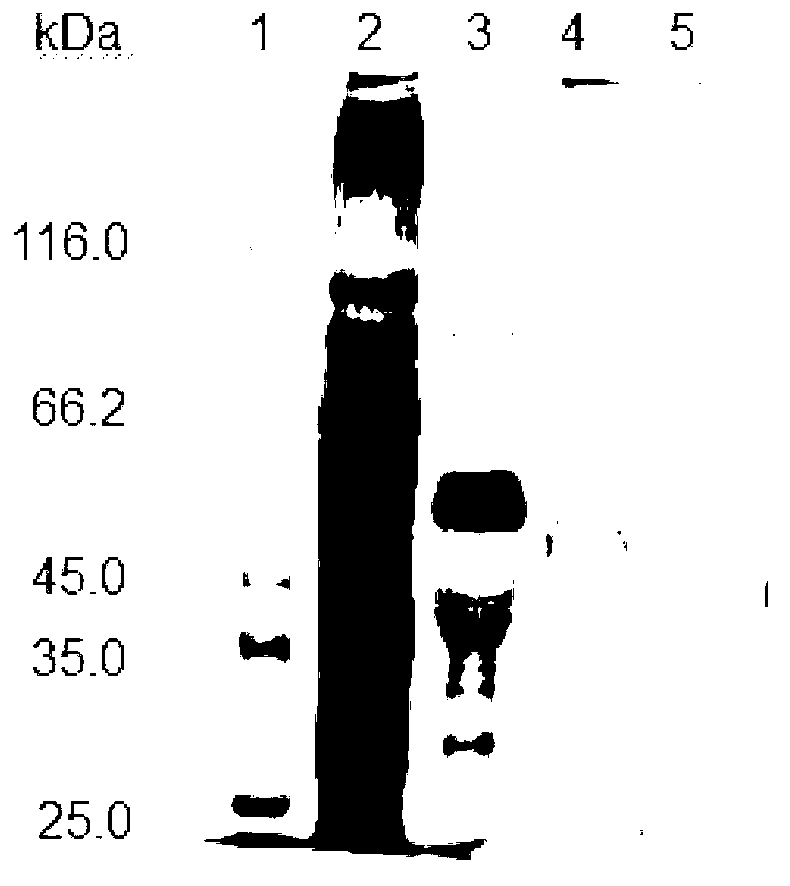

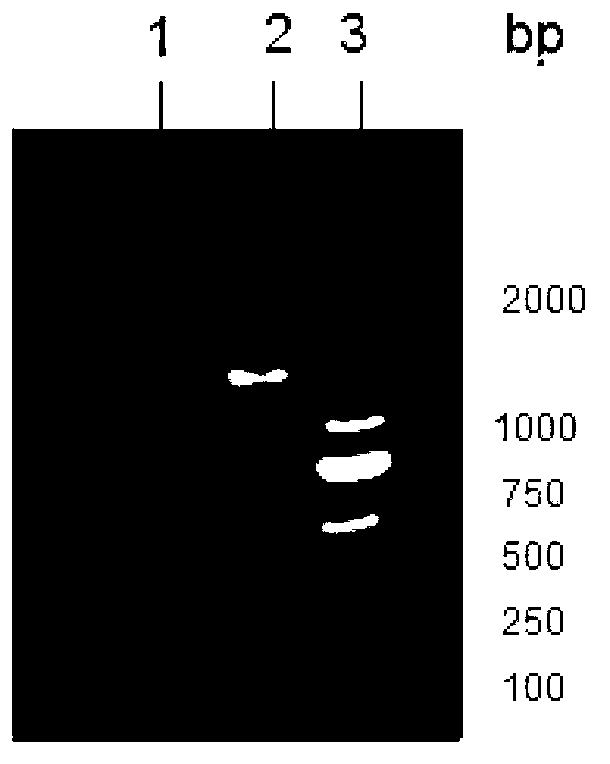

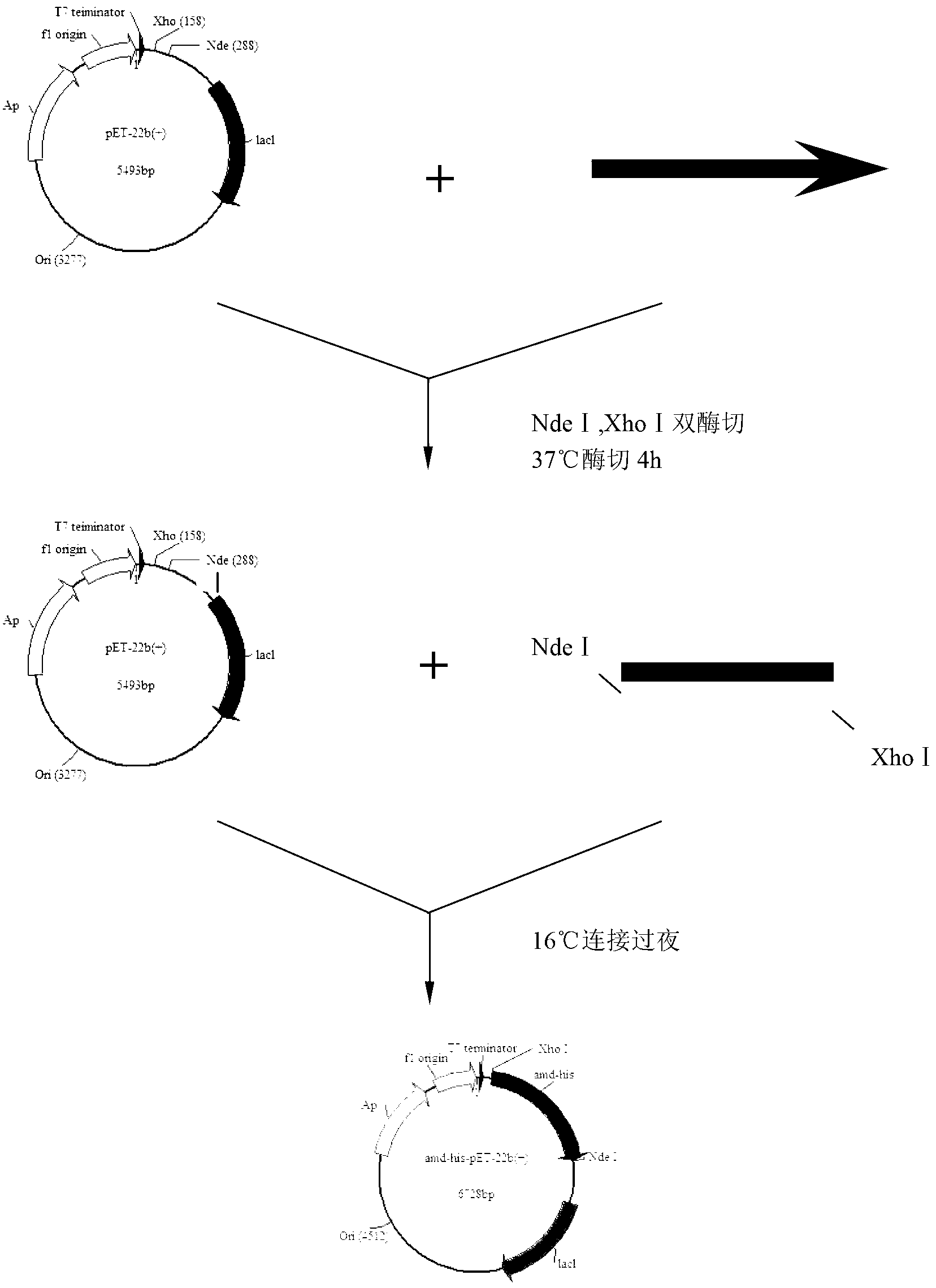

[0039] Example 3: This experiment illustrates the purification procedure of carboxyethylhydantoinase.

[0040] Buffer A: 0.02mol / L Tris-HCl, pH9.0,

[0041] Weigh 15 g of fermented bacteria (see the fermentation method of the screening process in Example 1 for details) and dissolve in 60 ml of buffer A to prepare a bacterial suspension. After ultrasonication (ultrasonic time 3s, intermittent time 5s, power 400W, protection temperature 25°C, whole process 10min, repeat 3 times), centrifuge at 10000r / min for 30min at 4°C, and collect the supernatant. After 20%, 40%, 60%, 80% saturation ammonium sulfate graded precipitation. The precipitate was collected by centrifugation, dissolved in buffer A, transferred to a dialysis bag, dialyzed with the same buffer at 4°C, and then concentrated with polyethylene glycol-20000. Take the concentrated sample and put it on the DEAESepharose F.F anion exchange column, use buffer A and 1mol / L NaCl for linear gradient elution, and collect the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com