Preparation method of high-dielectric film

A high-dielectric and dielectric technology, applied in the field of preparing high-dielectric polymer composite films, can solve the problems of high dielectric breakdown strength, difficult to process films, low dielectric constant values, etc., and achieve excellent mechanical properties and cost. Effects of low and high dielectric constant values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

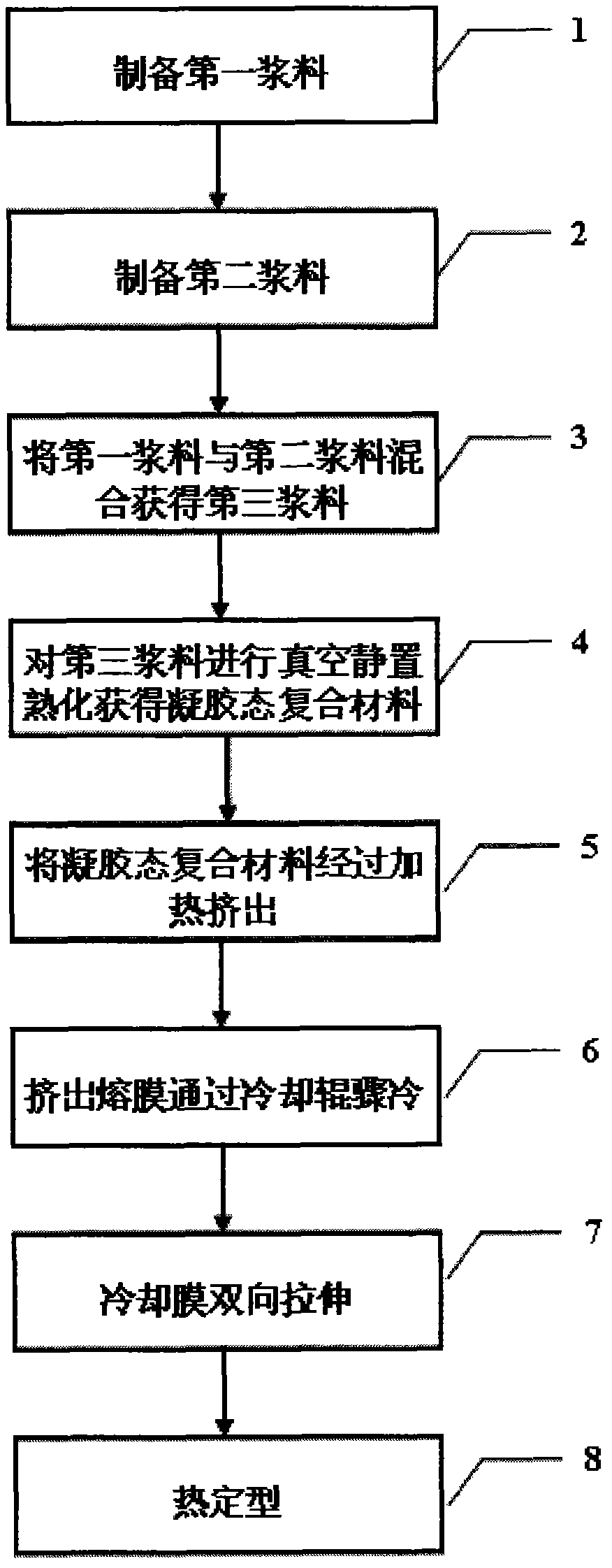

Method used

Image

Examples

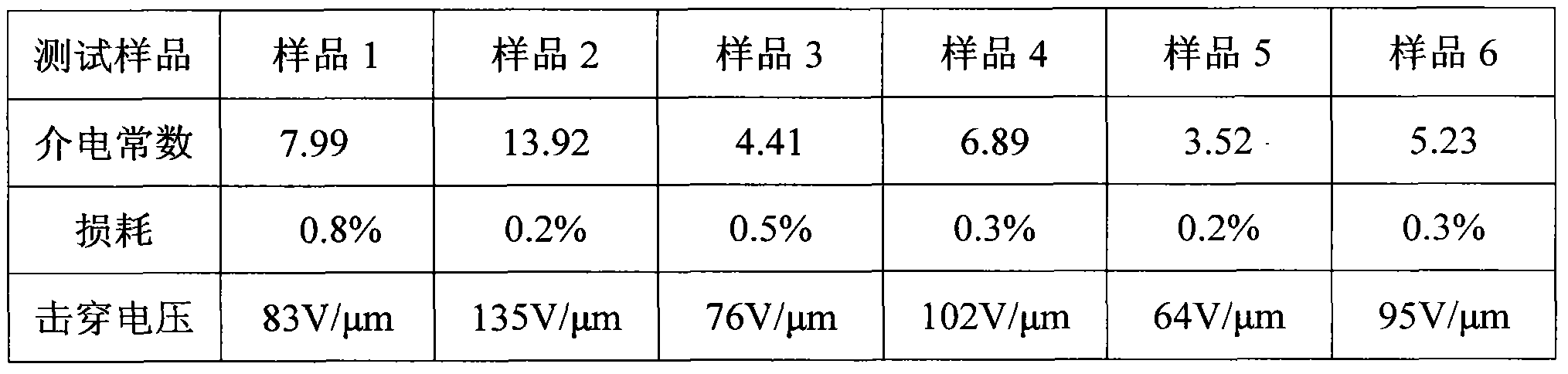

Embodiment 1

[0052] Weigh 500g polyvinylidene fluoride powder and 100g N,N-dimethylformamide ball mill and mix for 8-10h. The organic dielectric main material A is fully mixed with N, N-dimethylformyl to obtain the first slurry; the first slurry is subjected to vacuum static aging treatment for 2 to 4 hours, and the gel state composite material Film sample 1 (pure polyvinylidene fluoride film, no compounding) was obtained by heating extrusion, cooling and quenching, bidirectional film drawing, and heat setting.

Embodiment 2

[0054] Weigh 500g polyvinylidene fluoride powder and 100g N,N-dimethylformamide ball mill and mix for 1-4h. Make polyvinylidene fluoride powder and N,N-dimethylformyl fully mixed to obtain the first slurry; weigh 25g of polyprothoquinone and mix it with 100g of ethanol, and ultrasonically treat it for 1 to 4 hours to make polyprothoquinone Uniformly disperse in ethanol to obtain the second slurry; ball mill and mix the first slurry and the second slurry for 8-10 hours, so that the mixed slurry is fully and uniformly mixed to obtain the third slurry; vacuum the third slurry After aging treatment for 2-4 hours, the gel-state composite material was heated and extruded, cooled and quenched, bidirectionally stretched, and heat-set to obtain film sample 2 (polyvinylidene fluoride / polyhydroquinone composite film).

Embodiment 3

[0056] Weigh 500g polyethersulfone powder and 100g acetone ball mill and mix for 8-10h. The polyether sulfone and acetone are fully mixed to obtain the first slurry; the first slurry is subjected to vacuum standing and aging treatment for 2 to 4 hours, and the gel state composite material is heated and extruded, cooled and quenched, and bidirectionally drawn. Film and heat setting to obtain film sample 3 (pure polyethersulfone film, no compounding).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com