Method for synthesizing propylene by using methanol

A technology for methanol synthesis and propylene, applied in chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, molecular sieve catalysts, etc., can solve the problems of inability to meet industrial application requirements, low propylene selectivity, and low propylene selectivity, etc. Achieve the effect of improving service life, slow catalyst deactivation and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

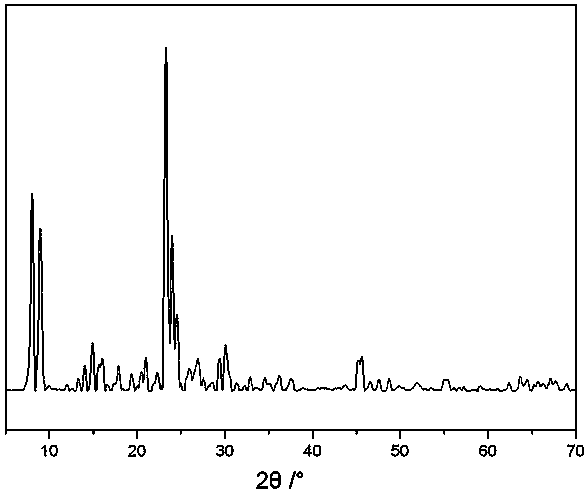

Image

Examples

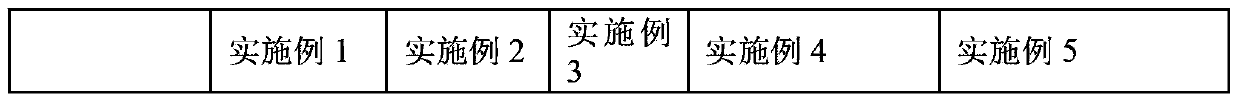

Embodiment 1

[0039] Add methanol solution to the first fixed bed reactor, catalyze with dimethyl ether catalyst, the mass ratio of water and methanol in the added methanol solution is 2:1, and the mass space velocity of the methanol solution is 1h -1 , the reaction temperature catalyzed by the dimethyl ether catalyst is 300°C, and the reaction generates an intermediate mixture. Among them, the dimethyl ether catalyst used was purchased from Southwest Chemical Research and Design Institute Co., Ltd.

[0040] The intermediate mixture is sent to the second fixed-bed reactor, and the ZSM-5 molecular sieve catalyst with a silicon-aluminum ratio of 50 is used for catalytic reaction. The temperature in the second fixed-bed reactor is 400°C, and the pressure is increased to 0.1MPa to form a mixed Hydrocarbon, the consumption of catalyst is 10 grams.

[0041] The mixed hydrocarbons are sent to the separator for separation, propylene is separated, and the remaining components are returned to the se...

Embodiment 2

[0045] Add methanol solution to the first fixed bed reactor, catalyze with dimethyl ether catalyst, the mass ratio of water and methanol in the added methanol solution is 2:1, and the mass space velocity of the methanol solution is 1h -1 , the reaction temperature catalyzed by the dimethyl ether catalyst is 300°C, and the reaction generates an intermediate mixture. Among them, the dimethyl ether catalyst used was purchased from Southwest Chemical Research and Design Institute Co., Ltd.

[0046] The intermediate mixture is sent to the second fixed-bed reactor, and the ZSM-5 molecular sieve catalyst with a silicon-aluminum ratio of 75 is used for catalytic reaction. The temperature in the second fixed-bed reactor is 420°C, and the pressure is increased to 0.05MPa to form a mixed Hydrocarbon, the consumption of catalyst is 10 grams.

[0047] The mixed hydrocarbons are sent to the separator for separation, propylene is separated, and the remaining components are returned to the s...

Embodiment 3

[0051] Add methanol solution to the first fixed bed reactor, catalyze with dimethyl ether catalyst, the mass ratio of water and methanol in the added methanol solution is 2:1, and the mass space velocity of the methanol solution is 1h -1 , the reaction temperature catalyzed by the dimethyl ether catalyst is 300°C, and the reaction generates an intermediate mixture. Among them, the dimethyl ether catalyst used was purchased from Southwest Chemical Research and Design Institute Co., Ltd.

[0052] The intermediate mixture is sent to the second fixed-bed reactor, and the ZSM-5 molecular sieve catalyst with a silicon-aluminum ratio of 250 is used for catalytic reaction. The temperature in the second fixed-bed reactor is 490°C, and the pressure is increased to 0.5MPa to form a mixed Hydrocarbon, the consumption of catalyst is 10 grams.

[0053] The mixed hydrocarbons are sent to the separator for separation, propylene is separated, and the remaining components are returned to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com