Hot-rolled steel strip vertical stripe defect eliminating method

A technology of longitudinal stripes and hot-rolled strip steel, which is applied in the field of steel rolling, can solve the problems of material safety reduction, accelerated steel plate corrosion, resource waste, etc., and achieve the effect of eliminating longitudinal stripe defects, reducing contact pressure and improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

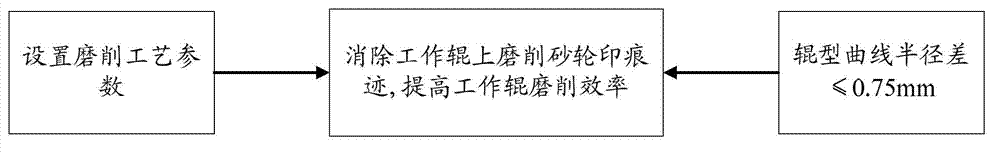

[0020] see figure 1 , a method for eliminating longitudinal stripe defects of hot-rolled steel strip provided in an embodiment of the present invention, comprising:

[0021] ①. Set the grinding process parameters:

[0022]

[0023] ;

[0024] By reducing the speed of the grinding wheel, increasing the speed of the rolls in the rough grinding and fine grinding stages, reducing the speed of the rolls in the first semi-finishing stage, increasing the speed of the rolls in the second and third semi-finishing stages, reducing the speed of the pallet, reducing the grinding wheel and roller Surface contact pressure and increase the number of fine grinding passes to eliminate the grinding wheel marks on the work roll;

[0025] ②. The grinding efficiency can be improved by setting the radius difference of the CVC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com