Reverse polymer solar cell with dual electron transport layer structure

A dual-electron transmission, solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as low power consumption, high photogenerated electron collection efficiency, and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

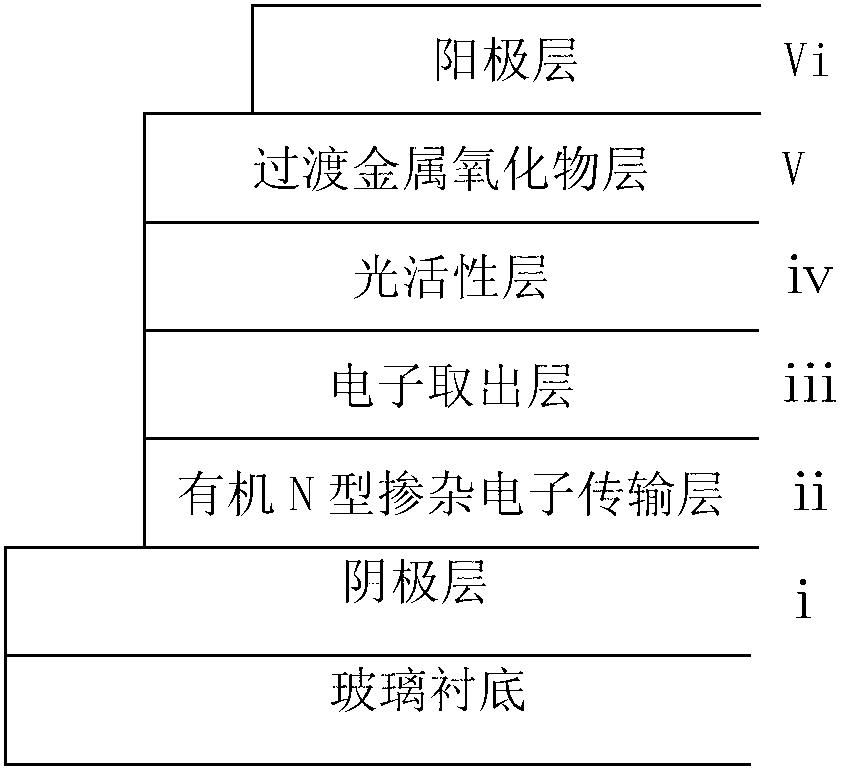

[0055] Prepare the structure as ITO with a thickness of 100nm / PMMA with a thickness of 10nm:C 60 :LCV=1:20:2 / Amorphous TiO with a thickness of 10nm 2 / P3HT:PC with a thickness of 80nm 61 BM=12:10 / MoO with a thickness of 10nm 3 A reverse polymer solar cell with a double electron transport layer structure of Al with a thickness of 100nm.

[0056] The reverse polymer solar cell with double electron transport layer structure is composed of a layer of ITO cathode layer with a thickness of 100nm on a glass substrate, a layer of PMMA with a thickness of 10nm deposited on the ITO cathode layer:C 60 : LCV thin film organic N-type doped electron transport layer, one layer deposited on PMMA:C 60 : Amorphous TiO with a thickness of 10nm on the organic N-type doped electron transport layer of LCV thin film 2 Thin-film electron extraction layer, a layer deposited on amorphous TiO 2 P3HT:PC with a thickness of 80nm on the thin film electron extraction layer 61 BM film photoactive layer...

Embodiment 2

[0083] The preparation structure is ITO with a thickness of 100nm / PMMA with a thickness of 20nm:C 60 :LCV=1:5:0.1 / Amorphous ZnO with a thickness of 10nm / PCPDTBT:PC with a thickness of 150nm 71 BM=12:10 / MoO with a thickness of 10nm 3 A reverse polymer solar cell with a double electron transport layer structure of Al with a thickness of 100nm.

[0084] The reverse polymer solar cell with double electron transport layer structure is composed of a layer of ITO cathode layer with a thickness of 100nm on a glass substrate, a layer of PMMA with a thickness of 20nm deposited on the ITO cathode layer:C 60 : LCV thin film organic N-type doped electron transport layer, one layer deposited on PMMA:C 60 : An amorphous ZnO thin film electron extraction layer with a thickness of 10nm on the organic N-type doped electron transport layer of the LCV film, a layer of PCPDTBT with a thickness of 150nm deposited on the amorphous ZnO thin film electron extraction layer:PC 71 BM film photoactive ...

Embodiment 3

[0102] The preparation structure is Ag / PMMA with a thickness of 20nm / thickness of 10nm:C 60 :AOB=1:20:2 / Amorphous ZnO with a thickness of 10nm / P3HT with a thickness of 80nm:PC 61 BM=12:10 / MoO with a thickness of 10nm 3 A reverse polymer solar cell with a double electron transport layer structure of Al with a thickness of 100nm.

[0103] The reverse polymer solar cell with double electron transport layer structure is composed of a layer of Ag ITO cathode layer with a thickness of 20nm on a glass substrate, and a layer of PMMA:C with a thickness of 10nm deposited on the ITO cathode layer. 60 :AOB thin film organic N-type doped electron transport layer, one layer deposited on PMMA:C 60:Amorphous ZnO thin film electron extraction layer with a thickness of 10nm on the organic N-type doped electron transport layer of AOB film, a layer of P3HT:PC with a thickness of 80nm deposited on the amorphous ZnO thin film electron extraction layer 61 BM film photoactive layer, a layer deposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com