A sleeve-type helium temperature-controlled deposition sampling device for high-temperature gas-cooled reactors

A high-temperature gas-cooled reactor and sampling device technology, applied in cooling devices, control of nuclear reactions, reactors, etc., can solve the problems of single type of depositable fission products, low efficiency, contrast and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below with reference to the accompanying drawings and through the description of the embodiments. It should be noted that the "front end" and "rear end" herein are both defined with respect to the flow direction of the sample gas flow, wherein the "front end" refers to the upstream of the flow direction of the sample gas flow.

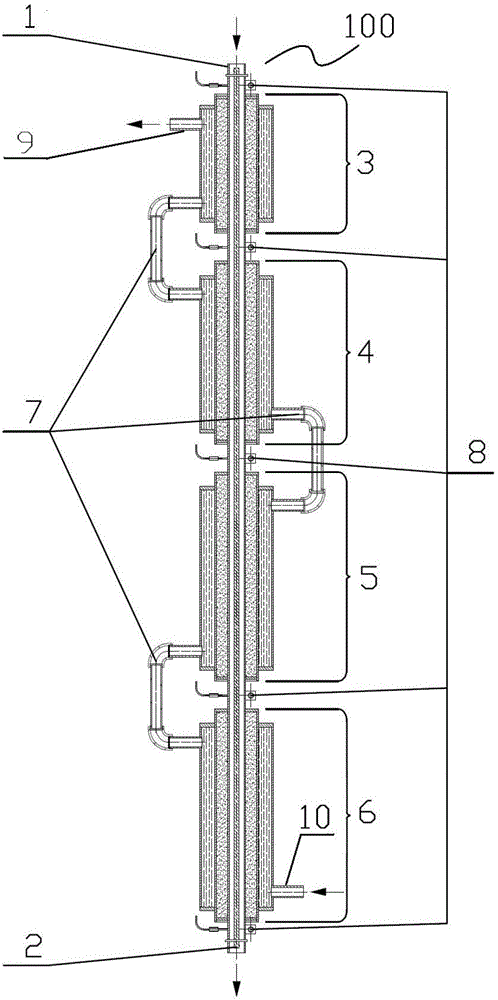

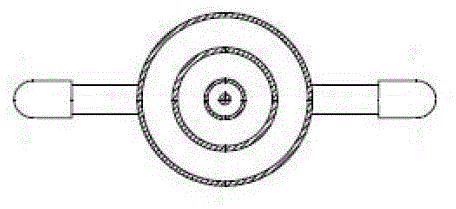

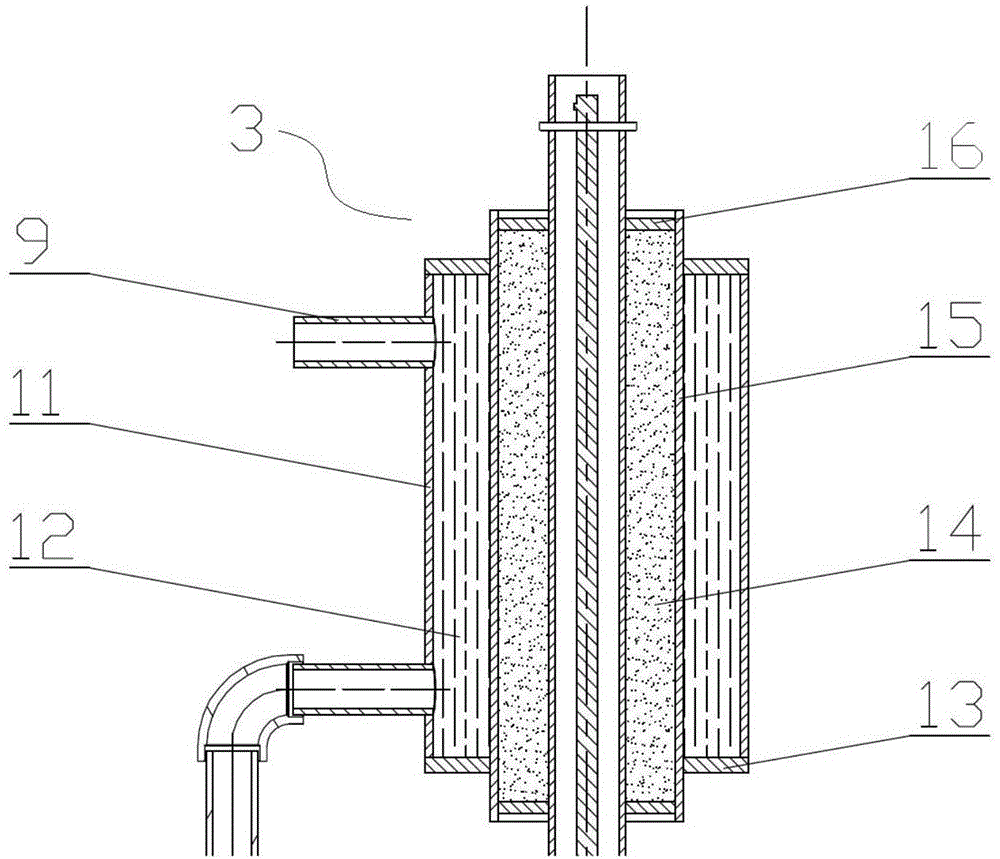

[0024] figure 1 , figure 2 Shown is a sleeve-type high-temperature helium temperature-controlled deposition sampling device 100 according to the present invention, which device includes a deposition sampling sleeve 1, a deposition sampling core fixed in the deposition sampling sleeve 1 and extending axially The rod 2 is fixed to the temperature control front unit 3, the first temperature control cascade unit 4, the second temperature control cascade unit 5 and the temperature control end unit 6 on the outer wall of the deposition sampling casing 1 at intervals along the axial direction....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com