Method for determining Laves phase content in steel

A phase content and workpiece technology, applied in the field of metallurgy, can solve the problems of complex sample preparation process of transmission electron microscope, troublesome carbide extraction and experimental process, randomness of test, etc., so as to improve the probability of successful test, save test time, Eliminates the troublesome effect of transmission sample preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

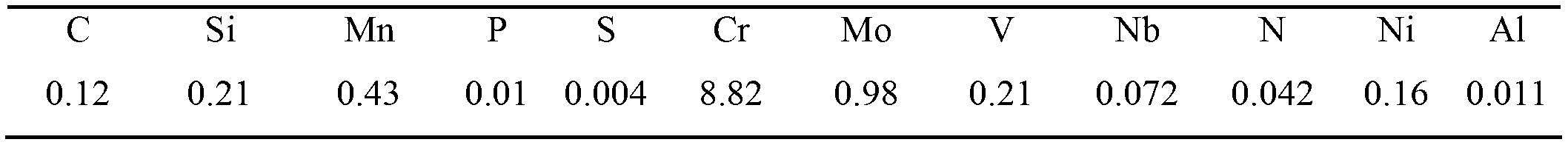

[0030] The composition is shown in Table 1. Samples were taken from T91 pipes with a specification of Ф60mm*10mm. The samples were subjected to an accelerated aging test at 675°C and 70MPa for 900 hours. After aging, the Laves phase content of the samples was quantitatively determined.

[0031] Table 1 is the standard composition of T91 steel in the implementation example

[0032]

[0033] The determination method is as follows:

[0034] Step 1: Use wire cutting to take out the sample from the pipe, wash it with alcohol acetone, blow dry, and use a small file to slowly file the material from the small sample into small particles. Be busy during the file to ensure that the temperature will not rise too high.

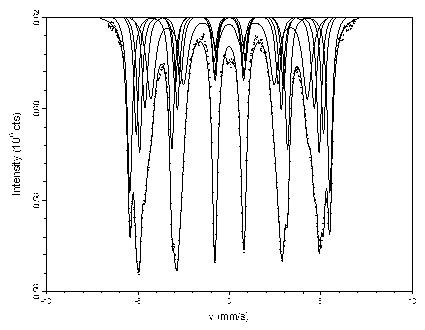

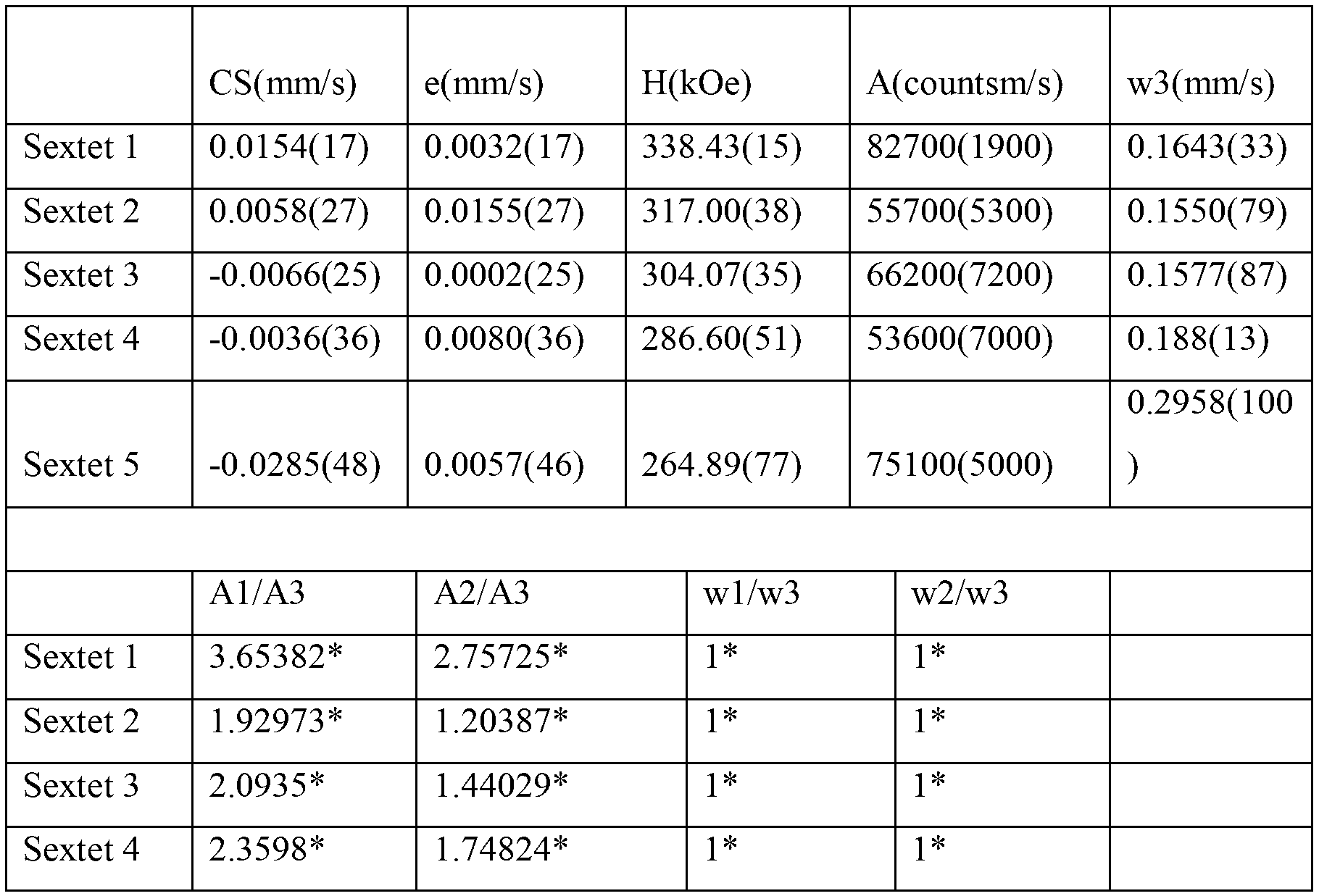

[0035] Step 2: Take the small particles and place them in the sample chamber of the Mössbauer instrument. The Mössbauer instrument adopts the transmission constant acceleration mode to measure the relationship between the gamma ray count and the modulation energy that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com