Testing device for catalytic coefficient of thermal shielding material and method for testing catalytic coefficient of thermal shielding material by utilizing device

A technology of thermal protection material and catalytic coefficient, applied in material excitation analysis, thermal excitation analysis, etc., can solve the problems of complex experimental process and long experimental period, and achieve the effect of accurate calculation and simple test method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

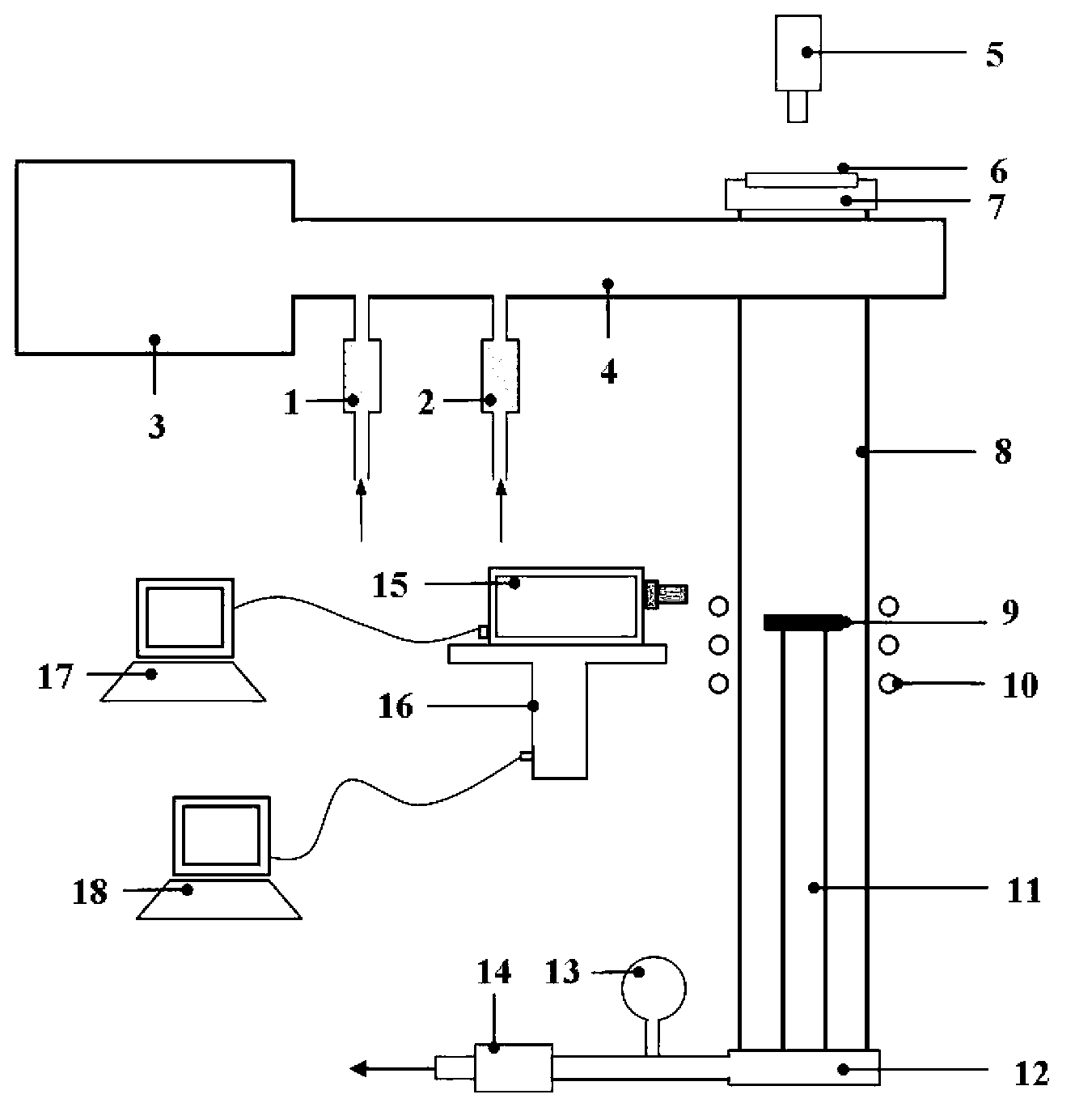

[0017] Specific implementation mode 1: Combination figure 1 , This embodiment is a thermal protection material catalytic coefficient testing device, including a carrier gas flow meter 1, an inert gas flow meter 2, a microwave power source 3, a waveguide 4, a double color pyrometer 5, calcium fluoride glass 6, a A mechanical seal part 7, a quartz tube 8, an electromagnetic induction heating coil 10, a zirconia bracket 11, a second mechanical seal part 12, a pressure gauge 13, a vacuum pump 14, a spectrometer 15, a mechanical lift table 16, a spectrometer signal receiving computer 17 and machinery Lifting platform control computer 18; the carrier gas flowmeter 1 and the inert gas flowmeter 2 are respectively connected to the waveguide 4, the microwave power source 3 and the waveguide 4 are connected together to form a plasma generation system, the quartz tube 8 and the waveguide 4 is connected, the calcium fluoride glass 6 is sealed and fixed on the upper part of the quartz tube ...

specific Embodiment approach 2

[0019] Specific implementation manner two: combination figure 1 This embodiment is a method for testing the catalytic coefficient of a thermal protective material by using a thermal protective material catalytic coefficient test device, which is specifically completed as follows:

[0020] 1. First, put the sample 9 to be tested on the zirconia support 11 of the thermal protection material catalytic coefficient test device, and then charge the carrier gas into the waveguide 4 through the carrier gas flow meter 1 at a flow rate of 10mL / min~300mL / min At the same time, fill the waveguide 4 with inert gas through the inert gas flowmeter 2 at a flow rate of 1mL / min~50mL / min, and control the flow rate of the inert gas to the carrier gas flow rate to 1:(4~99), control the waveguide 4 The internal gas pressure is 1Pa~1000Pa; 2. Start the electromagnetic induction heating coil 10 through the quartz tube 8 to heat the sample 9 to be tested, and heat the sample 9 to be tested from room tempe...

specific Embodiment approach 3

[0021] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the carrier gas described in step 1 is oxygen, nitrogen or air. Others are the same as the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com