Small block model pressing equipment for simulating rock mass structure

A technology for simulating rock masses and blocks, which is applied in the field of fine and rapid pressing equipment, can solve the problems of restricting the progress of geomechanical model tests and technology development, the shape of molds, single size, and huge workload, so as to improve the production speed and Quality, masonry processing is convenient, and the effect of reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

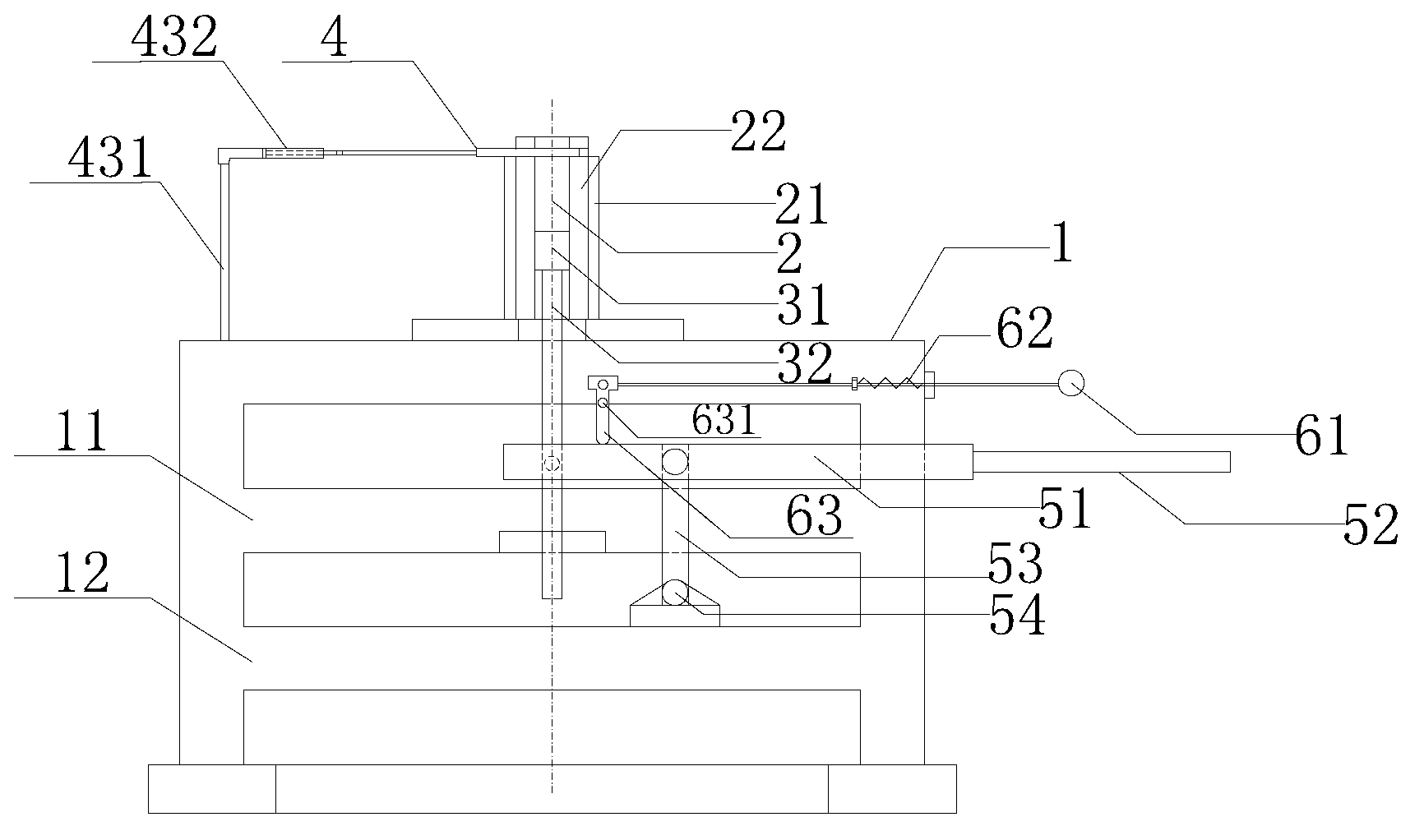

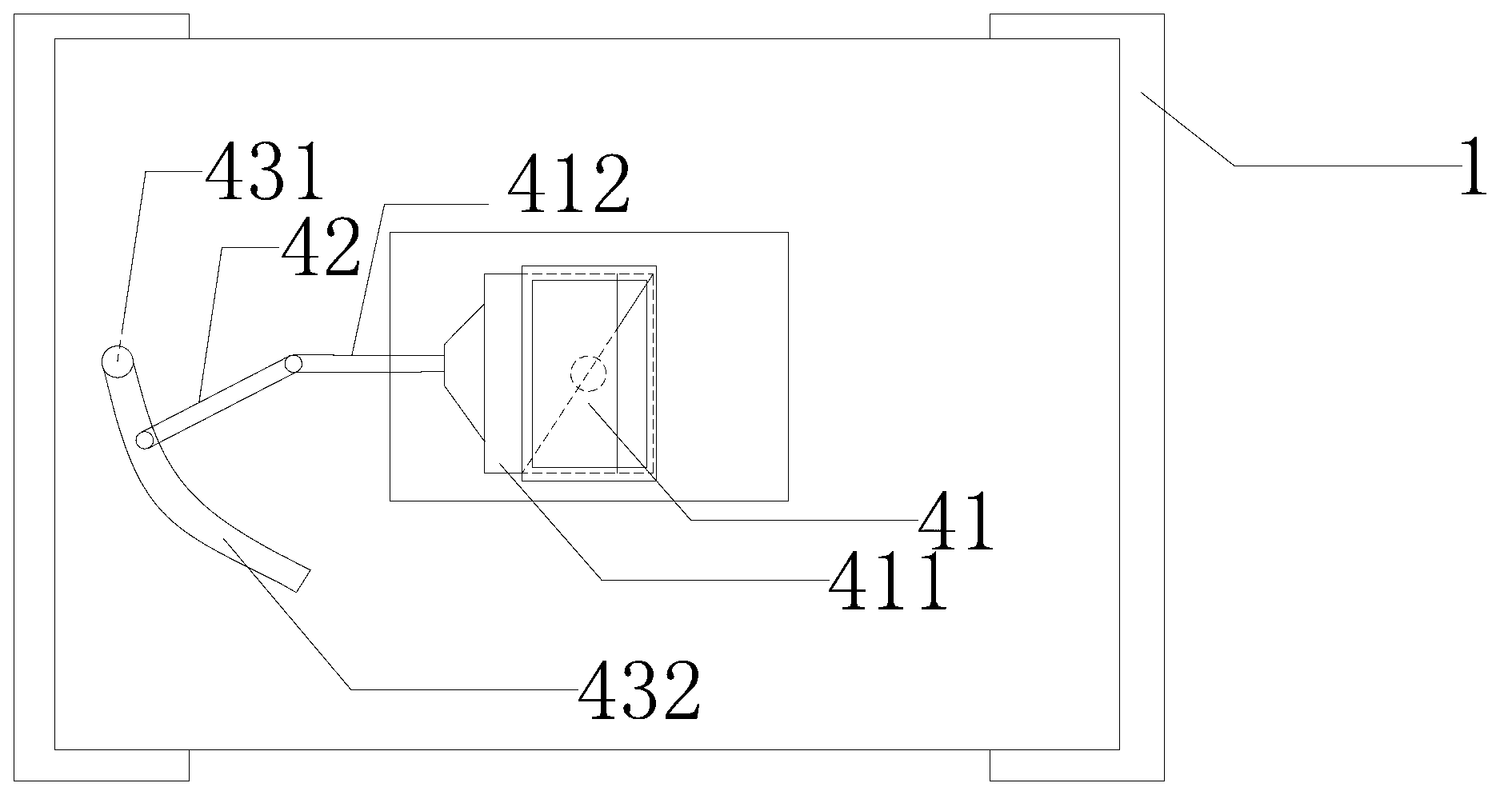

[0014] The present invention proposes a fine and fast compaction device for a small block model simulating rock mass structure, which is described in detail in conjunction with the accompanying drawings and embodiments as follows:

[0015] Pressing equipment structure of the present invention such as figure 1 As shown, the device includes a frame base 1, a small block mold 2 fixed on the frame base 1, a top block 3 on the mold, a push-pull cover plate 4, a pressure lever 5 and a limiter pull rod 6; wherein, the small block The mold 2 and the push-pull cover plate 4 are installed on the upper surface of the frame-type base 1, and the top block 3 of the mold is arranged on the lower part of the small block mold 2, and its upper end surface is inserted into the cavity of the small block mold 2 simulating the rock mass. Pull rod 6 places pressure lever 5 one ends.

[0016] An example of this device is figure 1 , figure 2 As shown, the specific implementation of each part is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com