Pipeline connection invisible variable-diameter bushing and method of use thereof

A core-filling and invisible technology, applied in the direction of pipes/pipe joints/fittings, passing components, mechanical equipment, etc., can solve the problems of prolonging the pipeline construction period, waste of steel pipe wall thickness, high cost, etc., and achieve stable and reliable sealing system, sealing system Robust, inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

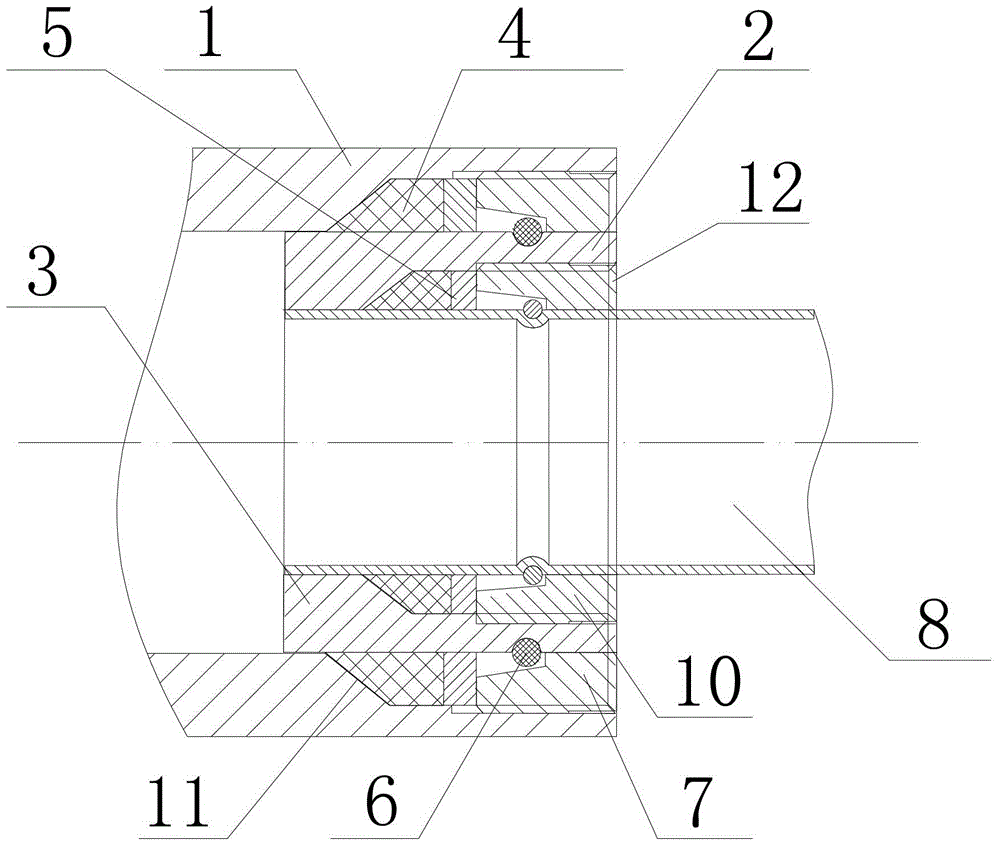

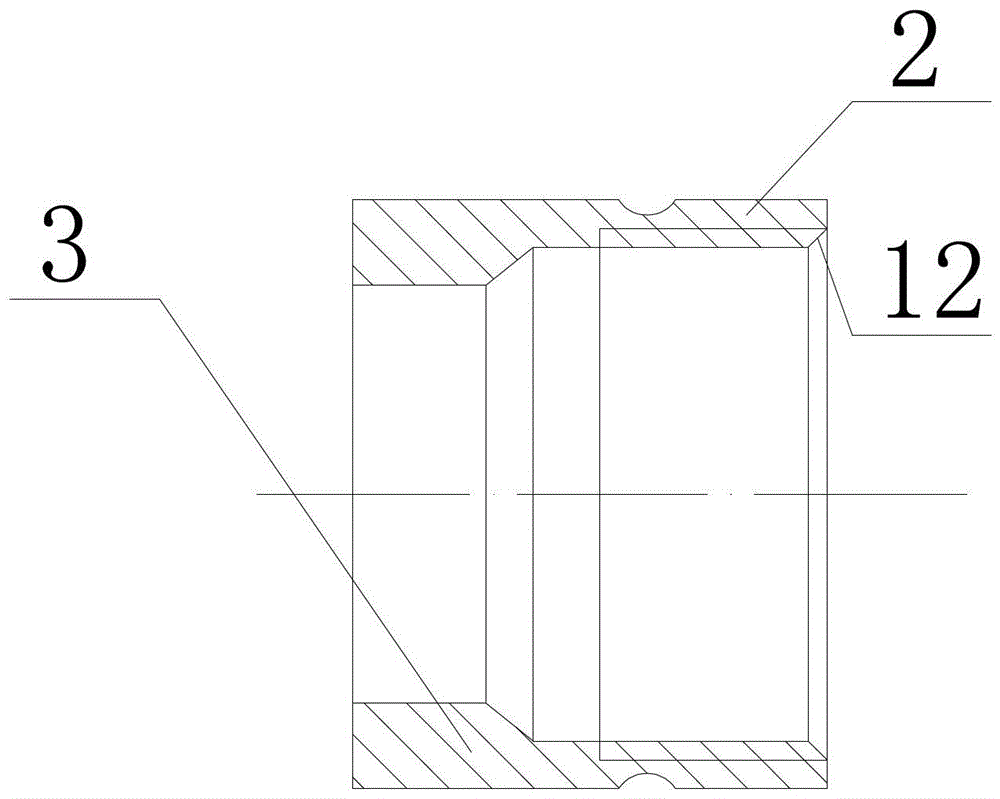

[0019] Such as Figure 1-Figure 2 The shown pipe connection invisible variable-diameter bushing includes a pipe fitting 1 and a bushing body 2, and the bushing body includes a stainless steel part 3; the stainless steel part 3 is provided with a first sealing ring 4 in sequence , a gasket 5, a snap ring 6 and a first compression nut 7, the snap ring is set in the groove on the surface of the stainless steel part; the first compression nut 7 is screwed to the pipe fitting 1.

[0020] The pipe connection invisible variable-diameter bushing also includes a smaller-diameter pipe body 8, and the smaller-diameter pipe body 8 is also sequentially provided with a second sealing ring, a gasket 5, a snap ring 6 and a second compression ring. Nut 10, the snap ring is set in the groove on the surface of the smaller diameter pipe body 8; the second compression nut 10 is screwed to the stainless steel part 3.

[0021] The outer inclined surface 11 of the first sealing ring 4 cooperates wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com