Thermal-insulating and decorating surface layer integrating vacuum thermal-insulating plate and roof tile

A vacuum insulation and decorative surface layer technology, which is applied to roofs, roofs, and roof coverings using tiles/slate tiles, can solve problems such as cracking, falling off, and hollowing of the decorative surface layer, and achieve rich materials and reduce construction procedures , the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

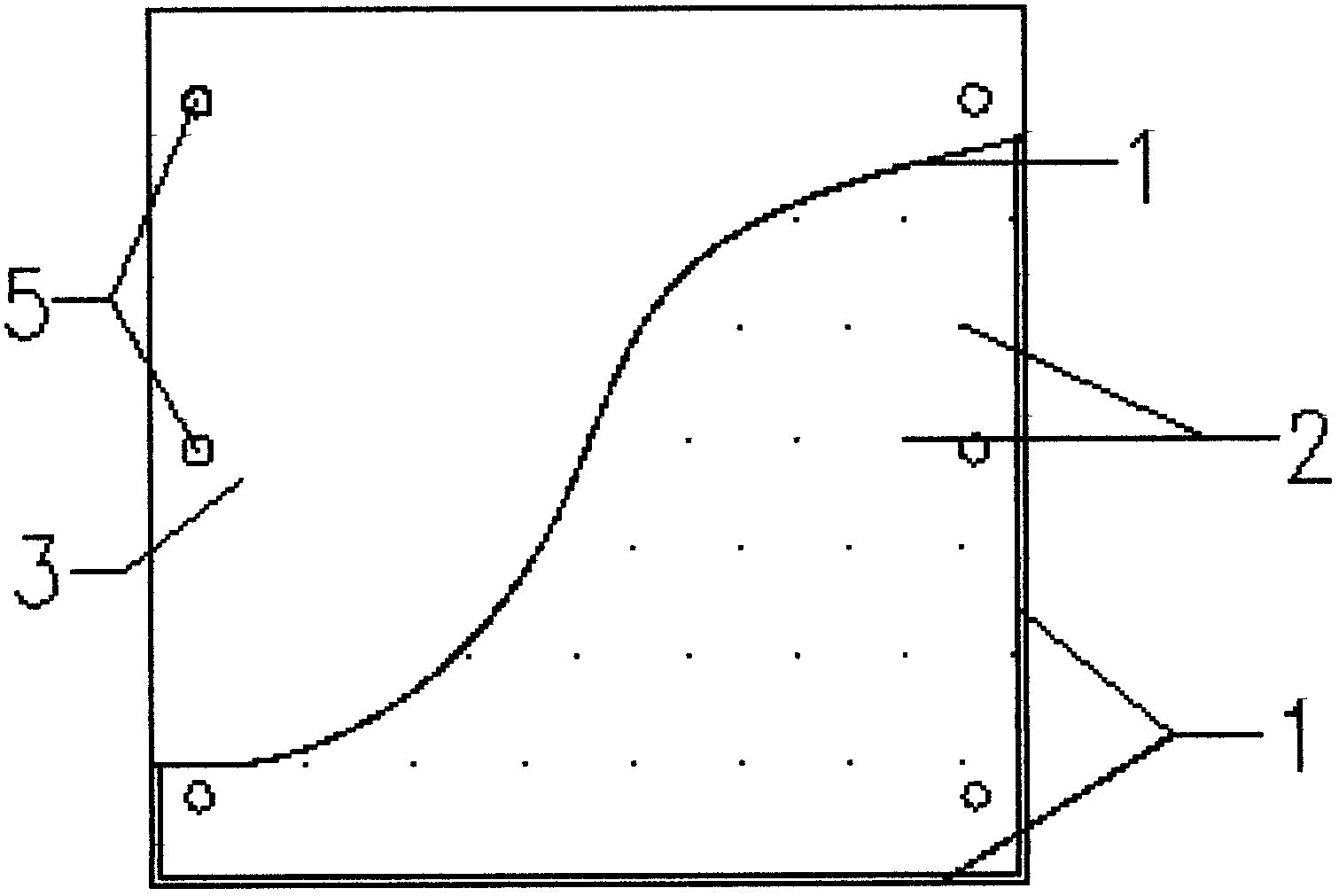

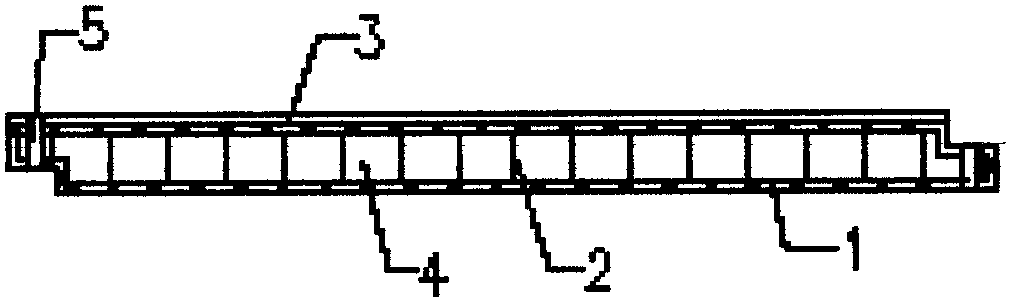

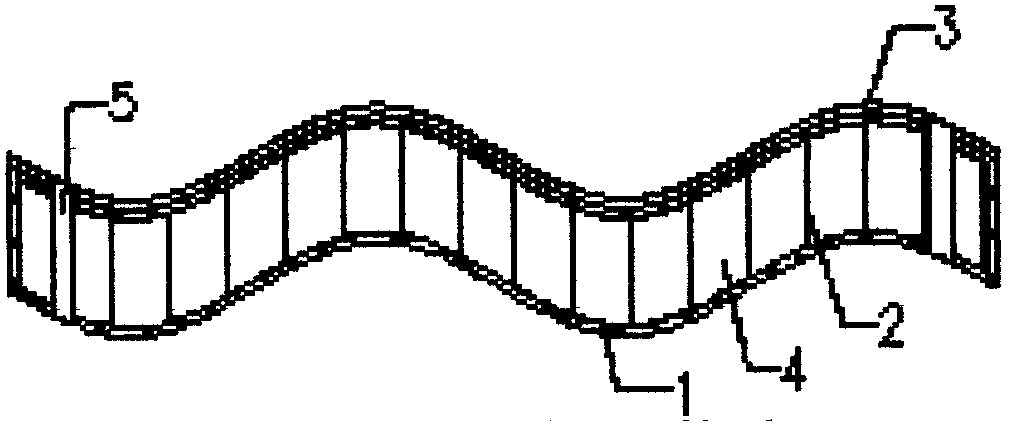

[0021] figure 1 and figure 2 Middle: 1. The metal frame of the vacuum insulation board is formed by splicing two metal plates, and the seams must be tightly sealed. 2 The internal support points of the vacuum insulation board are made of organic or inorganic substances that are not easy to conduct heat. 3. The outer decorative surface layer of the vacuum insulation board can be made into various architectural decorative surface layers by methods such as painting, baking varnish, spraying, electroplating, and making enamel materials. The design and color of the surface layer can be made into imitation tiles, imitation stone, drawing various patterns, stamping into various relief patterns, etc. 4 Vacuum layer inside the vacuum insulation board, inside the vacuum insulation board, the vacuum space formed after the air is pumped out. 5 The reserved holes for vacuum insulation boards, vacuum insulation roof tiles and keels are fixed, and bolts are used to pass through the reser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com