Double-steel-sheet and concrete combined core-tube structure with built-in corrugated steel sheets

A corrugated steel plate and concrete-filled steel tube technology, which is applied to building components, building structures, earthquake-proof and other directions, can solve the problem of failure to meet the requirements of seismic ductility structural measures for shear walls of super high-rise buildings, unreliable stress of tensile structure construction measures, and manual construction. Large workload and other problems, to avoid the construction of dense studs or bolts, reduce the construction workload, and achieve the effect of good energy consumption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

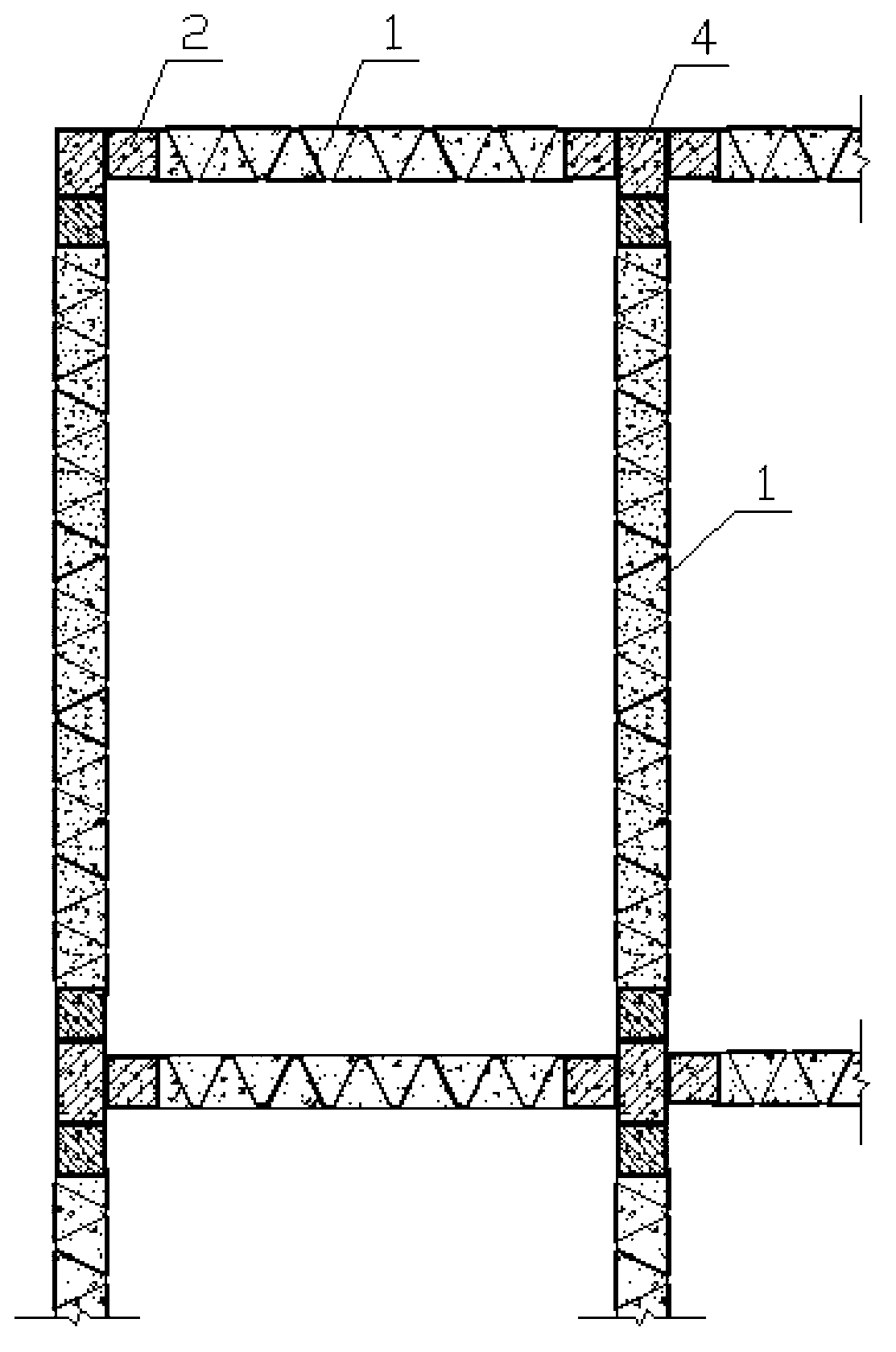

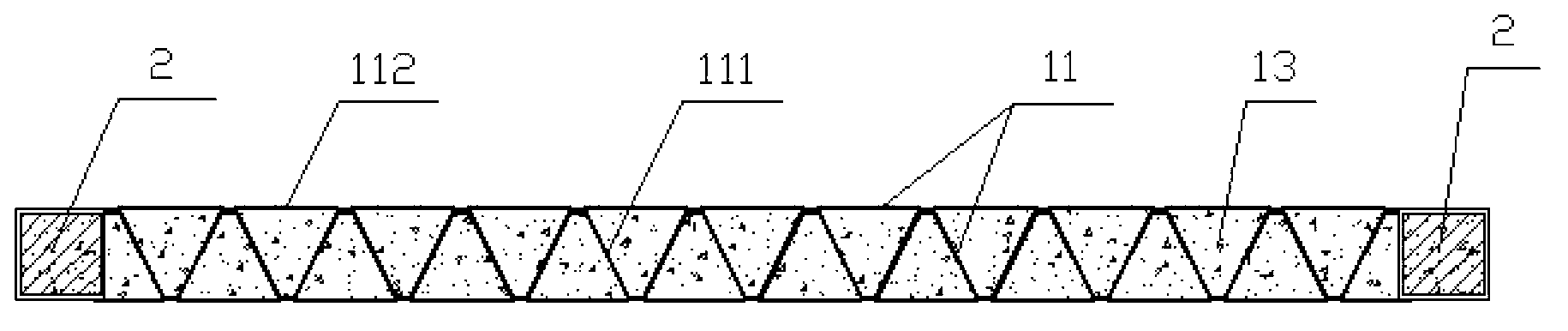

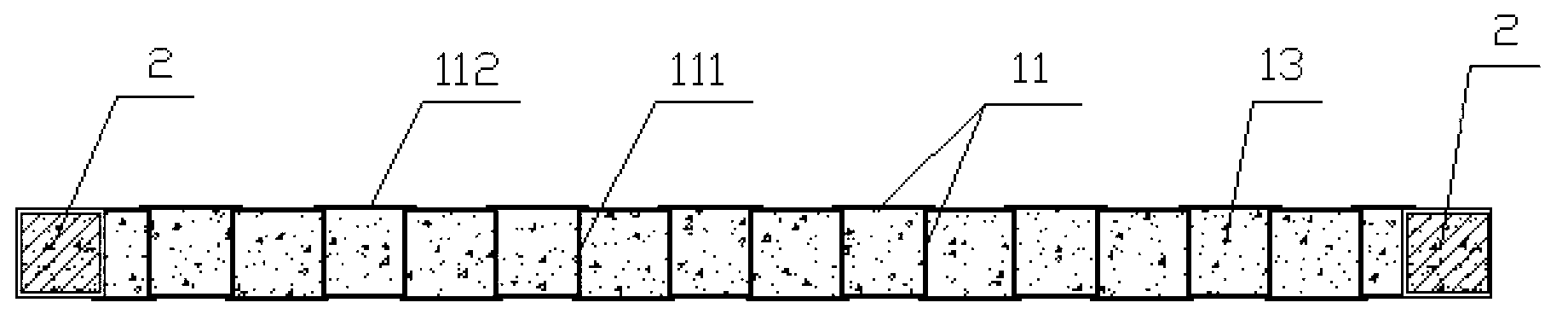

[0043] The double-steel-steel-concrete composite core tube structure with built-in corrugated steel plates of the present invention includes a strip-shaped grid-steel-concrete-concrete composite shear wall 1 , edge steel columns 2 , edge steel beams 3 , and end-part concrete-steel tube concrete core columns 4 . The long strip grid steel pipe concrete composite shear wall 1 is composed of a long strip grid steel pipe wall panel 11, a pipe inner tie bolt 12 and a pipe inner concrete column 13, and the long strip grid steel pipe wall The steel plate 111 and the steel strip cover plate 112 covering the vertical groove of the corrugated steel plate 111 are formed. The vertical groove of the corrugated steel plate 111 is covered by the steel strip cover plate 112 to form a cavity, and the concrete column 13 in the pipe is arranged in the cavity. The horizontal ends of the long grid steel tube concrete composite shear wall 1 are respectively connected with an edge steel column 2, and ...

Embodiment 2

[0046] The construction method of the double steel plate concrete composite core tube structure with built-in corrugated steel plate includes the following steps:

[0047] The first step: According to the design requirements, the corrugated steel plate 111 and the steel strip cover plate 112 are blanked. The inner surfaces of the corrugated steel plate 111 and the steel strip cover plate 112 are closely packed and welded with the tie bolts 12 in the pipe, and then the steel strip cover plate 112 Completely cover the groove of the corrugated steel plate 111, and weld the connection firmly to form a strip-shaped grid steel pipe wall plate 11 with tie bolts 12 in the welded pipe;

[0048] Step 2: Pour self-compacting high-strength concrete into the cavity formed by the steel strip cover plate 112 covering the groove of the corrugated steel plate 111 on the elongated grid steel pipe wall plate 11 to form the concrete column 13 in the pipe, and the concrete is hardened Afterwards, ...

Embodiment 3

[0052] An 80-story super high-rise steel structure building adopts a steel frame-core tube structure system. The bottom three floors are 4.8 meters high, and the rest are 3.6 meters high. Because it is a super high-rise building, in order to increase the seismic ductility requirements and reduce the wall thickness of the core tube shear wall structure, the core tube structure adopts a double steel plate concrete composite core tube structure with built-in corrugated steel plates to form a steel frame—a new composite structure core tube structure system. The design thickness of the shear wall of the core tube is 600mm. Since the building is an 80-story super high-rise building, it is necessary to greatly strengthen the binding capacity of the double steel plates. The long grid steel pipe concrete shear wall composed of V-shaped corrugated steel plates is selected. . The dimensions of the built-in V-shaped corrugated steel plate are 800mm in wavelength, 600mm in wave height, 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com