Semi-solid state metal molding multi-direction extrusion mold for refrigerator and air-conditioning compressor crankshafts

An air-conditioning compressor, semi-solid metal technology, applied in the direction of metal extrusion dies, etc., can solve the problems of pressure attenuation, high scrap rate, large material surplus, etc., and achieve shrinkage shrinkage defects, good mechanical properties, and large size high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings.

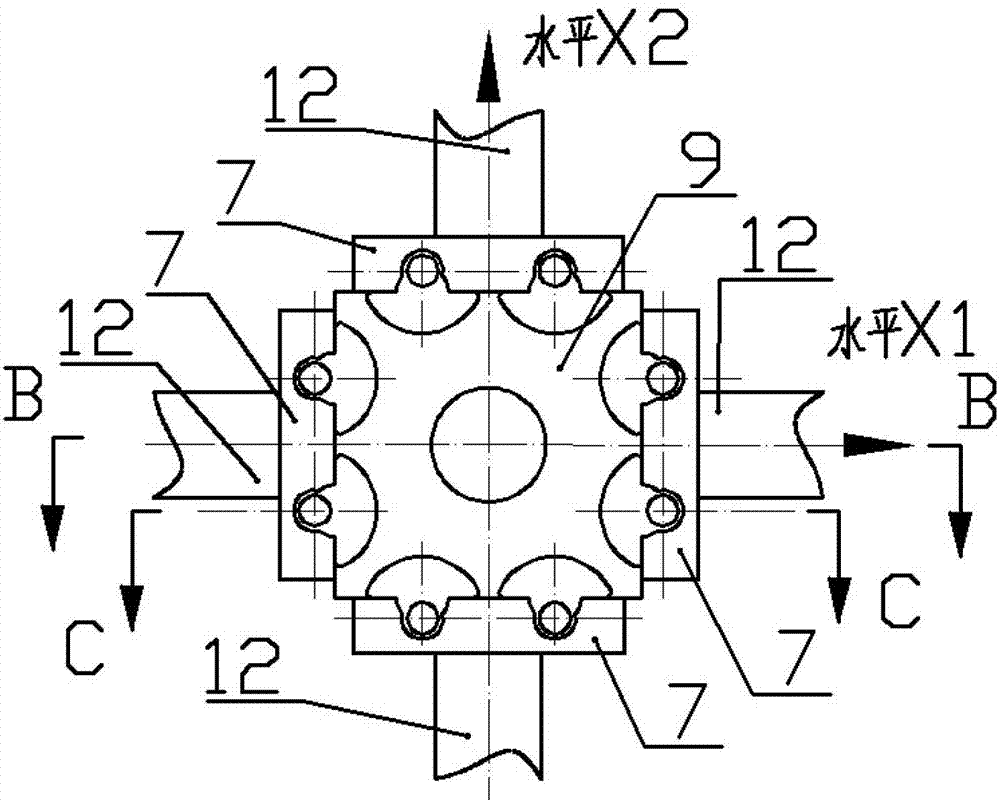

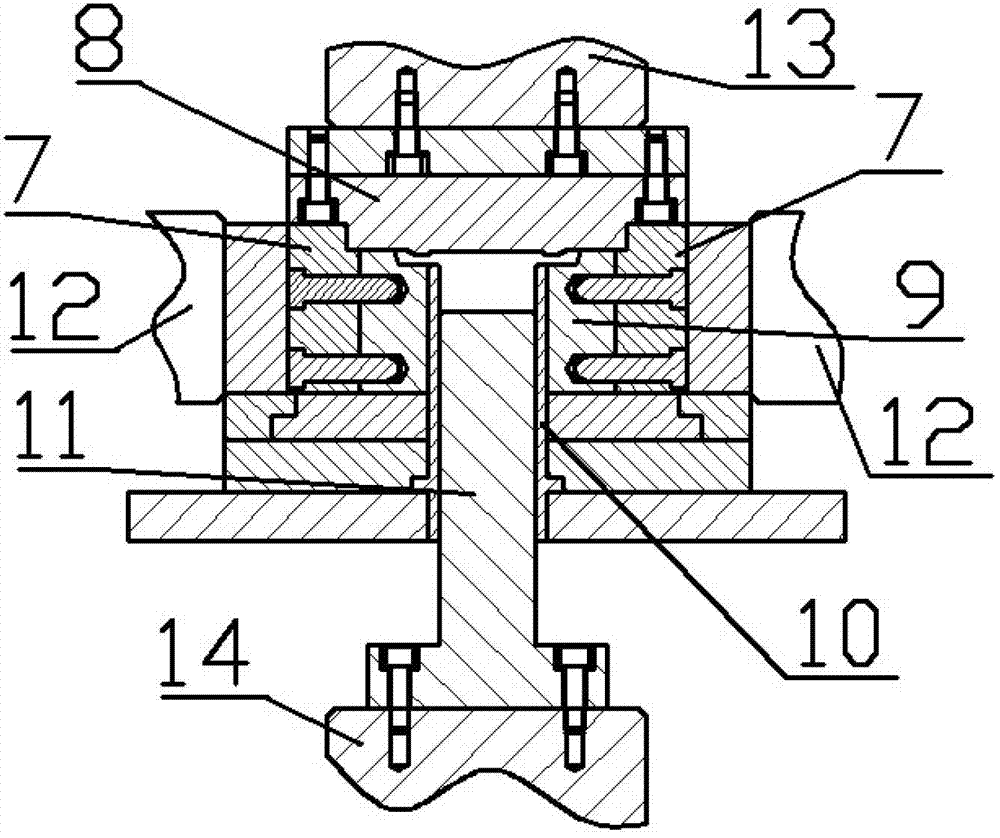

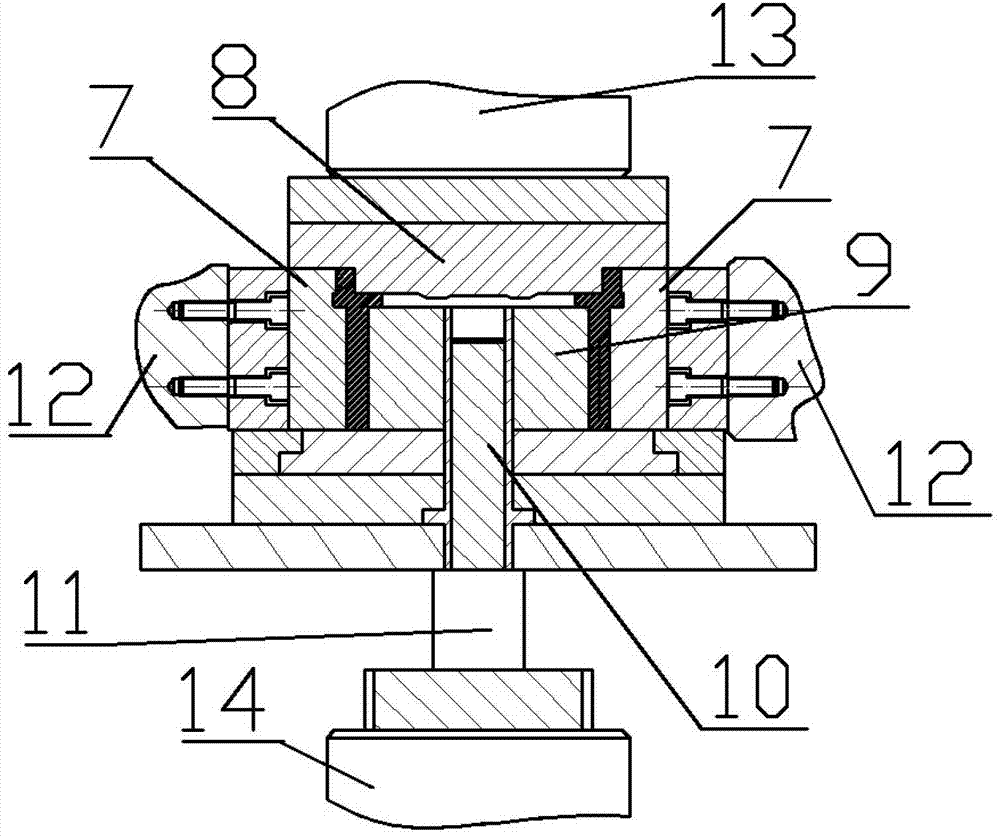

[0015] refer to figure 1 , figure 2 with image 3 , a refrigerator and air conditioner compressor crankshaft semi-solid metal forming multi-directional extrusion die, including a central fixed die 9, the upper end of the central fixed die 9 is inserted into a vertical movable die 8, the vertical movable die 8 and the top hydraulic cylinder piston rod 13 Connected, the central fixed mold 9 is symmetrically installed with horizontal movable molds 7 along the first horizontal X1 and second horizontal X2 directions respectively, the first horizontal X1 and the second horizontal X2 directions are perpendicular to each other, and the horizontal movable molds 7 are respectively and symmetrically distributed in the first The piston rods 12 of the horizontal hydraulic cylinders in the horizontal X1 and the second horizontal X2 directions are connected, and the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com