DC-DC converter

A DC-DC converter technology, applied in the field of DC-DC converters, can solve problems such as poor anti-noise ability, large package area, and increased cost, and achieve the goals of improving anti-noise ability, simplifying circuit structure, and reducing chip cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

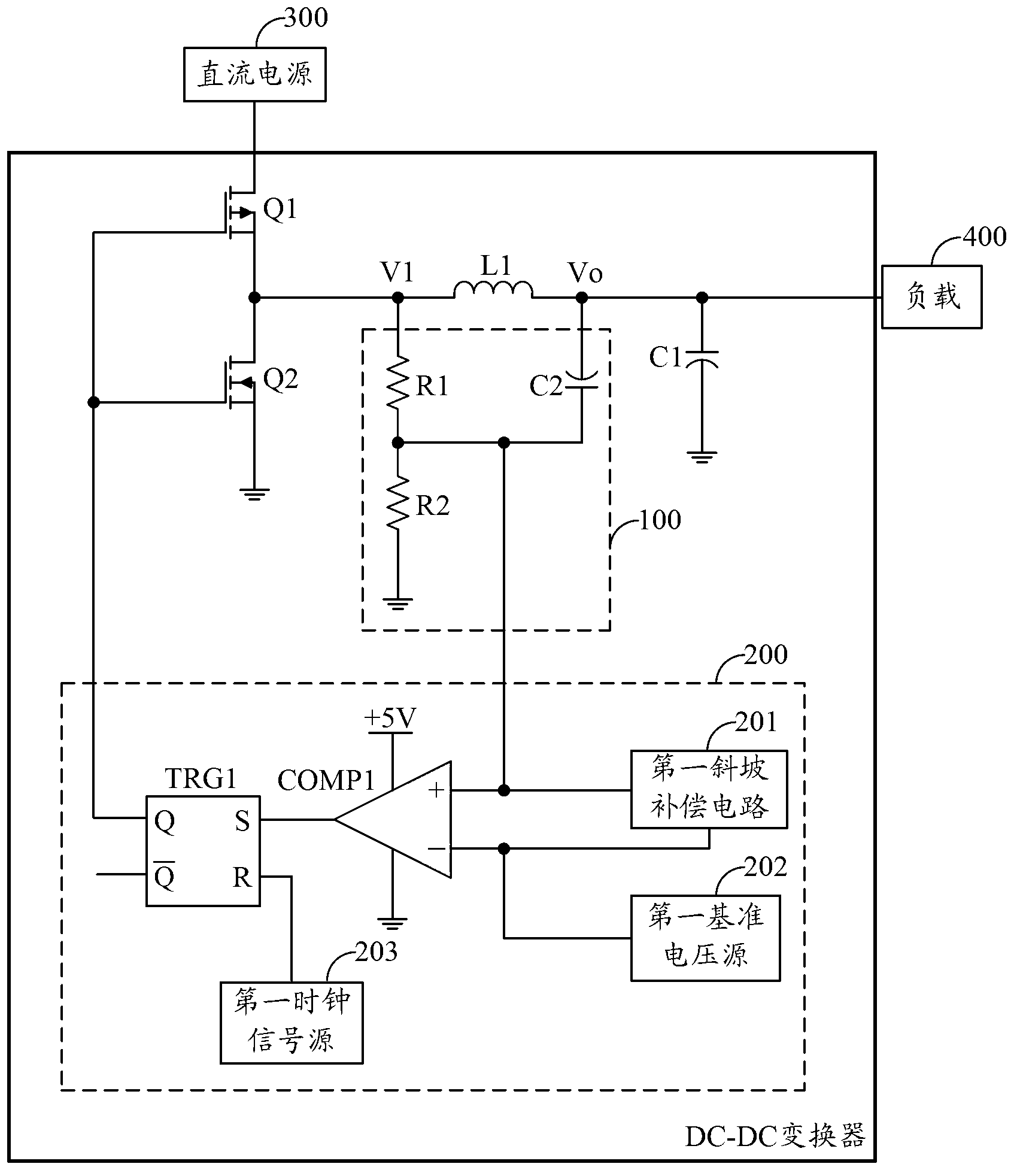

[0024] figure 2 An example circuit structure of the DC-DC converter provided by the first embodiment of the present invention is shown. For the convenience of description, only the parts related to the first embodiment of the present invention are shown, and the details are as follows:

[0025] As an embodiment of the present invention, the triangular wave generating module 100 includes a resistor R1, a resistor R2 and an energy storage capacitor C2, the first end of the resistor R1 is connected to the first input end of the triangular wave generating module 100, and the second end of the resistor R1 is connected to the resistor R2. The first end of the resistor R2 is connected to the positive pole of the energy storage capacitor C2, the second end of the resistor R2 is grounded, and the positive pole and the negative pole of the energy storage capacitor C2 are respectively connected to the output end and the second input end of the triangular wave generating module 100.

[0...

Embodiment 2

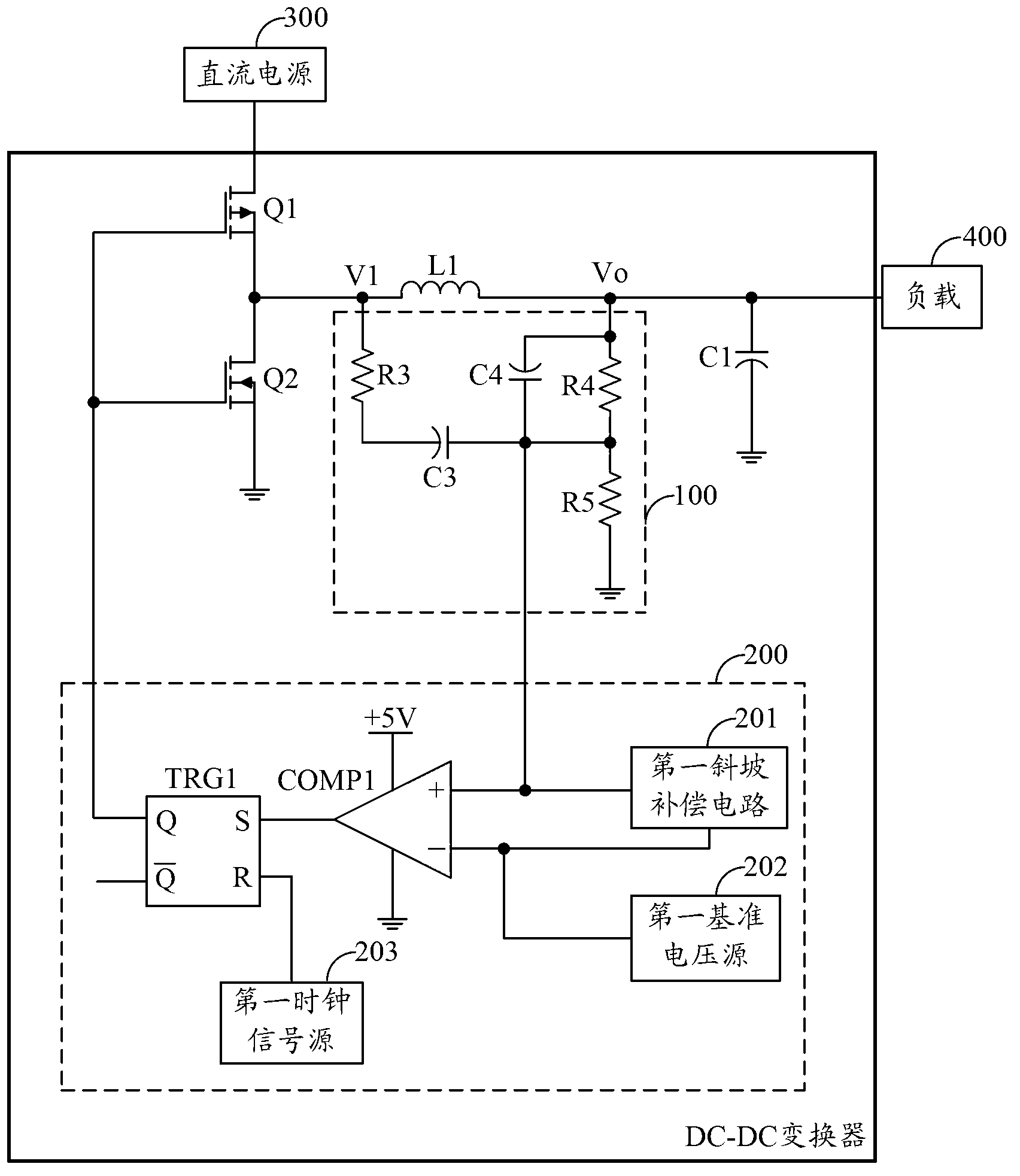

[0035] image 3 An example circuit structure of the DC-DC converter provided by the second embodiment of the present invention is shown. For the convenience of description, only the parts related to the second embodiment of the present invention are shown, and the details are as follows:

[0036] As an embodiment of the present invention, the triangular wave generating module 100 includes:

[0037] Resistor R3, energy storage capacitor C3, energy storage capacitor C4, resistor R4 and resistor R5;

[0038] The first end of the resistor R3 is connected to the first input end of the triangular wave generating module 100, the second end of the resistor R3 is connected to the negative pole of the energy storage capacitor C3, and the positive pole of the energy storage capacitor C3 is connected to the output end of the triangular wave generating module 100. The negative electrode of the energy storage capacitor C4 is connected to the first end of the resistor R4, the first end of t...

Embodiment 3

[0045] Figure 4 The example circuit structure of the DC-DC converter provided by the third embodiment of the present invention is shown. For the convenience of description, only the parts related to the third embodiment of the present invention are shown, and the details are as follows:

[0046] The internal structure of the triangular wave generating module 100 in the DC-DC converter provided in this embodiment is the same as the internal structure of the triangular wave generating module 100 provided in the first embodiment of the present invention, so details are not repeated here.

[0047] As an embodiment of the present invention, the switch control module 200 includes:

[0048] The second comparator COMP2, the second RS flip-flop TRG2, the second slope compensation circuit 210, the second reference voltage source 220 and the second clock signal source 230;

[0049] The inverting input terminal of the second comparator COMP2 is connected to the input terminal of the swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com