Red and green phosphorescent OLED device and manufacturing method thereof

A technology of red and green phosphorescence and a manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve problems such as quenching of light-emitting excitons, achieve high luminous efficiency and brightness, improve lifespan, and improve lifespan. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

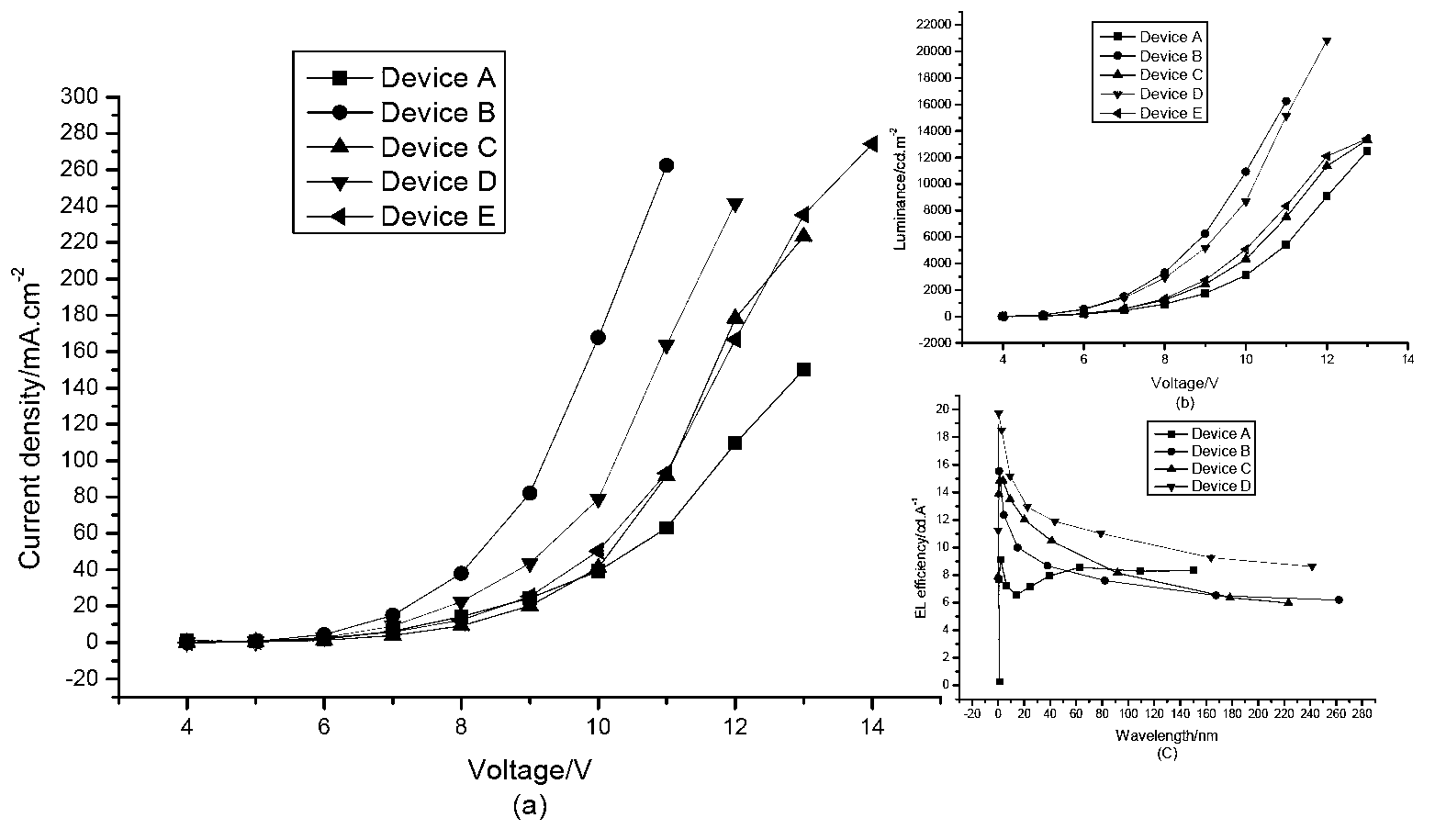

[0033] Device A:

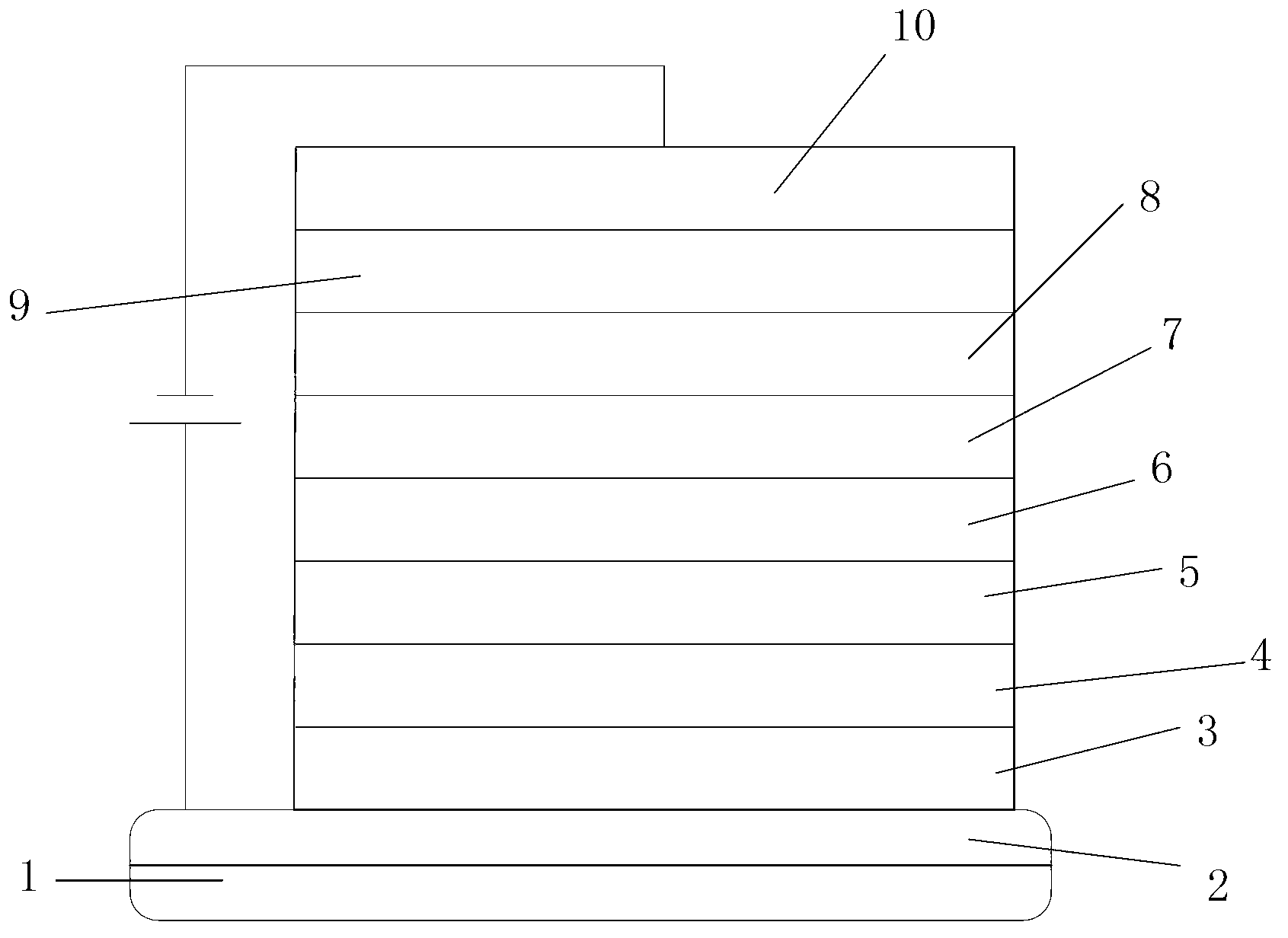

[0034] ITO / MoO 3 (40nm) / NPB (40nm) / TCTA (10nm) / CBP:2%R-4b (2.5nm) / CBP:14%GIr1 (25nm) / CBP:2%R-4b (2.5nm) / BCP (10nm ) / Alq 3 (40nm) / LiF (1nm) / Al (100nm)

Embodiment 2

[0036] Device B:

[0037] ITO / MoO 3 (40nm) / NPB (40nm) / TCTA (10nm) / CBP:14%GIr1 (25nm) / CBP:2%R-4b (5nm) / BCP (10nm) / Alq 3 (40nm) / LiF (1nm) / Al (100nm)

Embodiment 3

[0039] Device C:

[0040] ITO / MoO 3 (40nm) / NPB (40nm) / TCTA (10nm) / CBP:2%R-4b (5nm) / CBP:14%GIr1 (25nm) / BCP (10nm) / Alq 3 (40nm) / LiF (1nm) / Al (100nm)

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com