LED photonic crystal containing left-handed material and preparation method

A technology of left-handed materials and photonic crystals, applied in semiconductor devices, electrical components, circuits, etc., can solve problems that do not involve applications, achieve the effects of simplifying process steps, improving the quality of epitaxial structures, and reducing defect density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

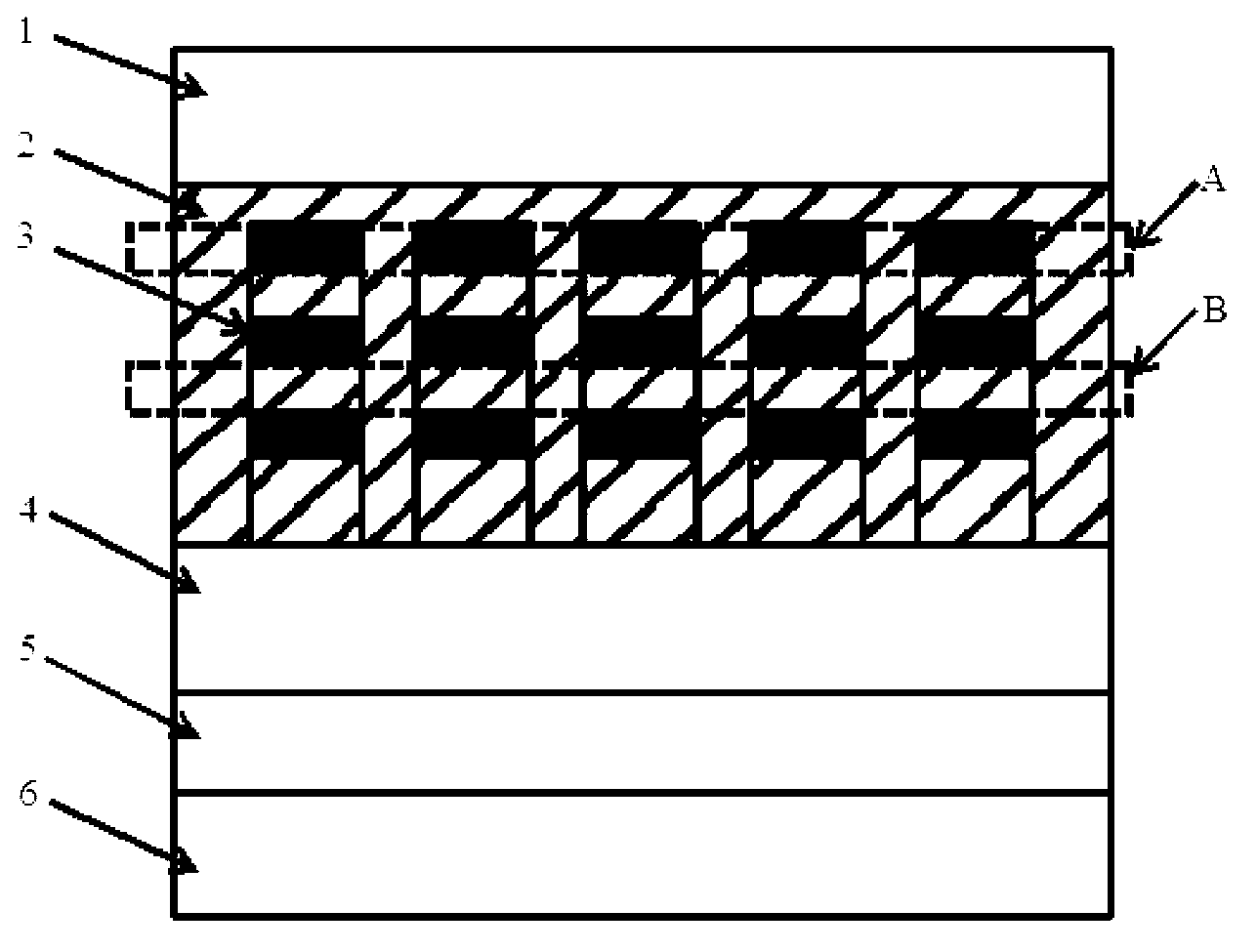

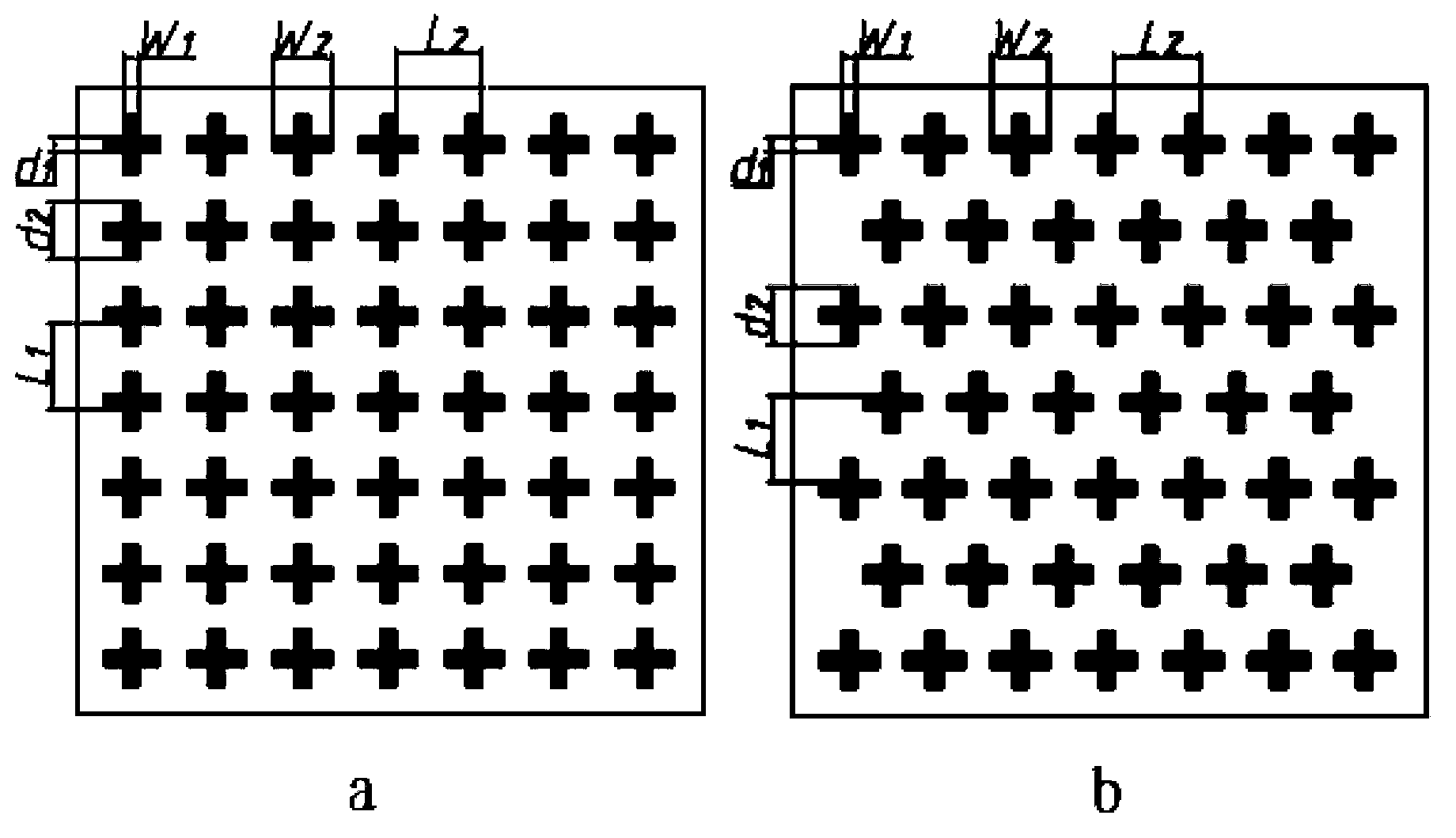

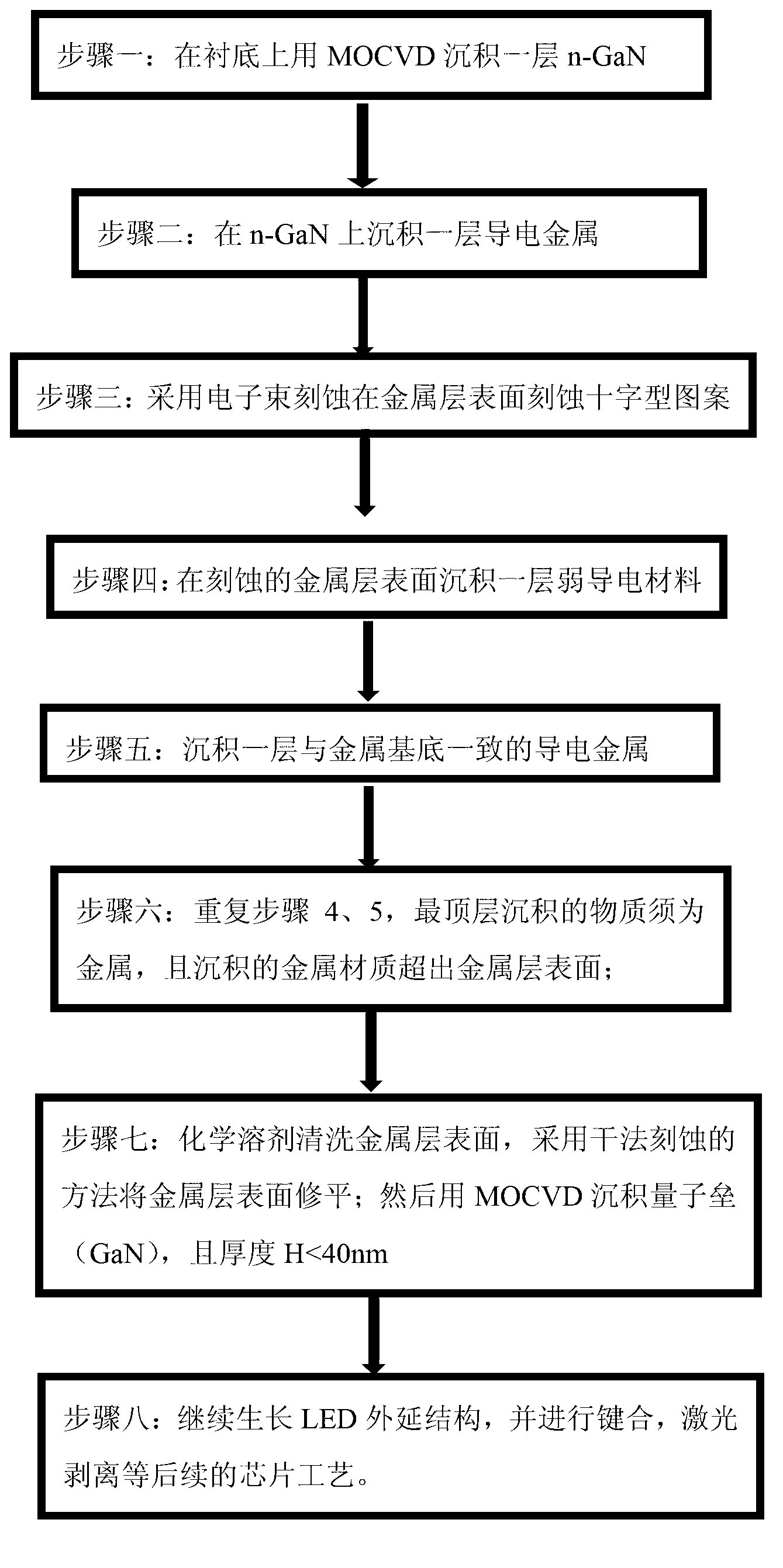

[0039] see figure 1 figure 2 , a LED photonic crystal containing left-handed materials, characterized in that, from top to bottom, it includes an n-GaN layer 1, a conductive metal substrate 2, a multi-quantum well active layer 4, a p-GaN layer 5, and a bonding metal layer 6. Among them, there is a quantum barrier GaN between the conductive metal substrate and the multi-quantum well active layer; the lower surface of the conductive metal substrate is etched upward with a "Swiss cross" void array with a depth greater than 100nm, and the plane of the "Swiss cross" void array is Upper rectangular distribution or triangular distribution, each cross gap is alternately filled with weakly conductive material 3 and conductive metal material homogeneous to the conductive metal base, each layer of weakly conductive material forms a left-hand material area A on the plane; each layer of conductive metal material The right-hand material area B on the plane is formed, and the left-hand mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com