Non-oil-stick triple-combination piston oil ring and fabrication method thereof

A combination of piston and non-stick oil technology, which is applied in the direction of piston rings, mechanical equipment, engine components, etc., can solve the problem of oil consumption that is prone to carbon deposits, and achieve good heat resistance and corrosion resistance, good non-stick oil performance, and acceleration The effect of mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

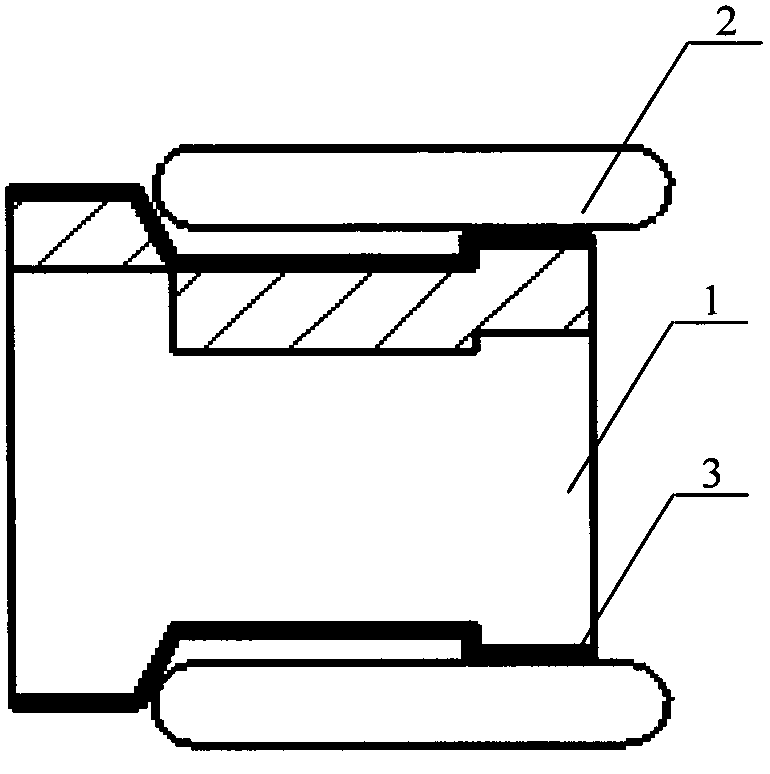

[0023] Specific implementation mode one: see figure 1 , The non-stick oil piston ring oil ring provided by the present invention includes a backing ring 1 , a wiper ring 2 , and a non-stick oil coating 3 coated on the upper and lower sides of the backing ring 1 . The implementation steps are as follows:

[0024] Step 1: Ultrasonic cleaning the lining ring to be coated to remove the oil stain on the surface of the lining ring.

[0025] Step 2: Carry out pre-chemical treatment on the surface of the lining ring, put the lining ring into the manganese phosphate solution for phosphating treatment, and form a thin phosphating layer on the surface of the lining ring, the treatment time is 3 to 5 minutes, and the temperature is 60~ 80℃, the thickness of phosphating layer is 1-3μm;

[0026] Step 3: After the phosphating treatment, wash the lining ring in pure water for 1 minute, and the water temperature is 60-70°C.

[0027] Step 4: After cleaning, put it into a drying oven for dryi...

specific Embodiment approach 2

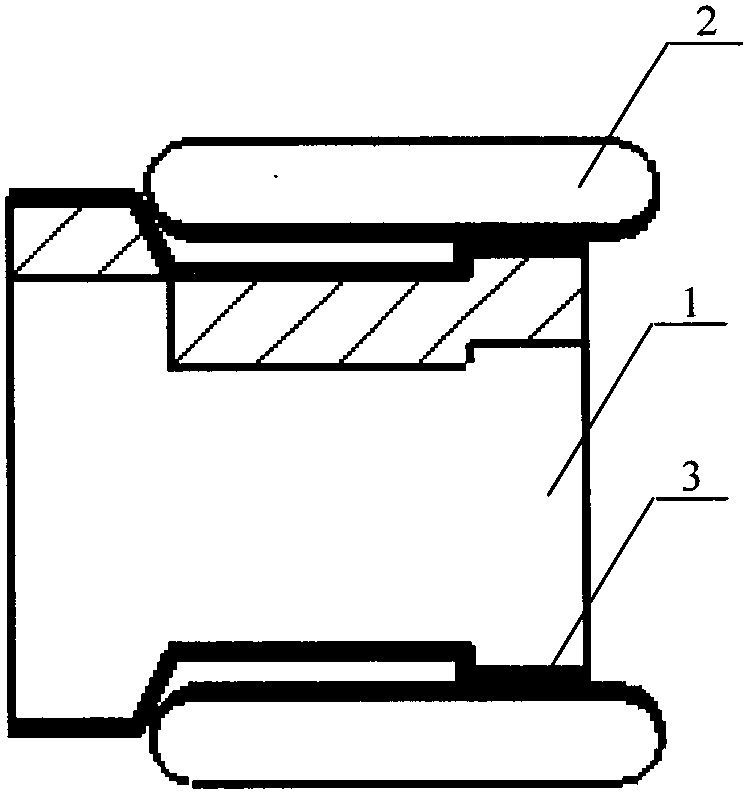

[0032] Specific implementation mode two: see figure 2 The non-stick oil piston ring oil ring provided by the present invention includes a backing ring 1, a scraper ring 2, and a non-stick oil coating coated on the upper and lower sides of the backing ring 1 and the scraper ring surface in contact with the backing ring. Layer 3. The implementation steps are as follows:

[0033] Step 1: Ultrasonic cleaning the lining ring and scraper to be coated to remove the oil on the surface of the lining ring.

[0034] Step 2: Carry out pre-chemical treatment on the surface of the backing ring and scraper, put the backing ring and scraper into the manganese phosphate solution for phosphating treatment, and form a thin phosphating layer on the surface of the backing ring and scraper, and treat The time is 3 to 5 minutes, the temperature is 60 to 80°C, and the thickness of the phosphating layer is 1 to 3 μm;

[0035] Step 3: After the phosphating treatment, put the lining ring and scraper...

specific Embodiment approach 3

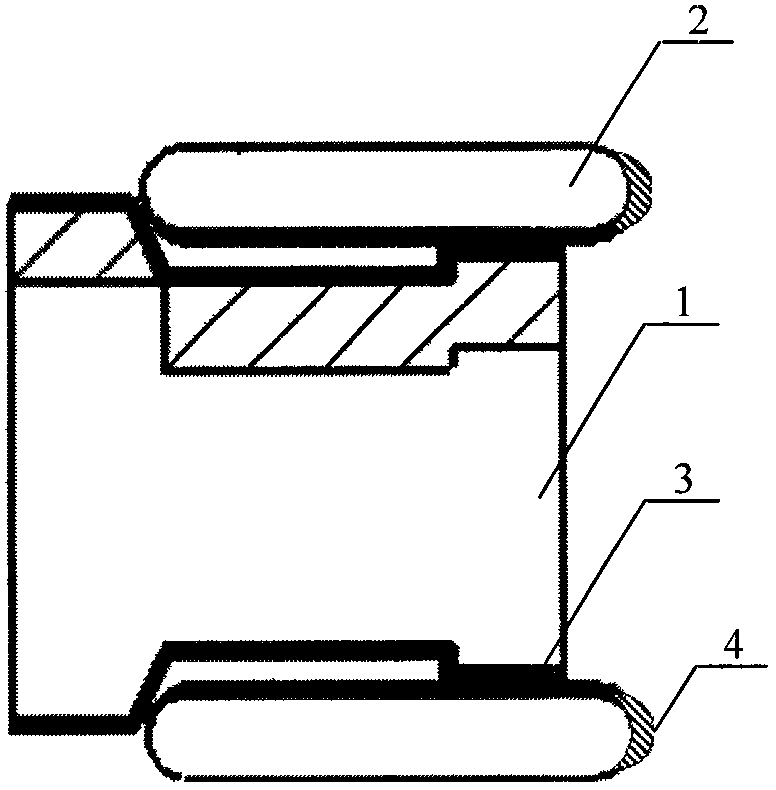

[0041] Specific implementation mode three: see image 3 The non-stick oil piston ring oil ring provided by the present invention includes a backing ring 1, a scraper ring 2, and a non-stick oil coating coated on the upper and lower sides of the backing ring 1 and the scraper ring surface in contact with the backing ring. Layer 3 is a plasma nitriding layer 4 formed on the outer surface of the wiper ring 2 by means of plasma nitriding. The implementation steps are as follows:

[0042] Step 1: Plasma nitriding the outer surface of the scraper ring by plasma nitriding;

[0043] Step 2: Ultrasonic cleaning the lining ring and scraper to be coated to remove the oil on the surface of the lining ring.

[0044]Step 3: Carry out pre-chemical treatment on the surface of the backing ring and scraper, put the backing ring and scraper into the manganese phosphate solution for phosphating treatment, and form a thin phosphating layer on the surface of the backing ring and scraper, and trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com