Red fluorescent luminescent material and preparation method thereof

A luminescent material and red fluorescence technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of different decay times of long afterglow phosphors, lack of long afterglow fluorescent luminescent materials, etc., and achieve stable product chemical properties and low production costs. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a preparation method of the red fluorescent luminescent material described in the above technical solution, comprising the following steps:

[0040] mixing a Ba-containing compound, an Eu-containing compound, an Al-containing compound and silicon dioxide to obtain a mixture;

[0041] The molar ratio of Ba element, M element, Eu element, R element, Al element, Ga element and silicon element in the mixture is (3.8-5.9999): (0-1): (0.0001-0.6): (0-0.6 ): (17~18): (0~1): 2;

[0042] The mixture is sintered in a reducing atmosphere to obtain a red fluorescent material.

[0043] Above in the present invention, at first various raw materials are mixed, obtain mixture, wherein:

[0044] The Ba-containing compound is preferably barium oxide, nitrate or hydroxide; the Al-containing compound is aluminum-containing oxide, nitrate or hydroxide.

[0045] The R-containing compound, the R-containing compound is an R-containing oxide or oxalate. The...

Embodiment 1

[0057] To analyze pure BaCO 3 , Analytical pure Al 2 o 3 , Analytical pure SiO 2 As raw material, with analytically pure B 2 o 3 As flux, BaCO 3 、Al 2 o 3 , SiO 2 and B 2 o 3 The molar ratio between them is 6:9:2:0.5. Accurately weigh the above substances, fully grind them evenly in an agate mortar, put them into a corundum crucible, then put them into a large corundum crucible, fill them with carbon rods, put them into Roast in a high-temperature furnace at 1350°C for 5 hours, cool naturally to room temperature, take out and grind to obtain a white powder sample, the actual composition of which is Ba 6 Al 18 Si 2 o 37 .

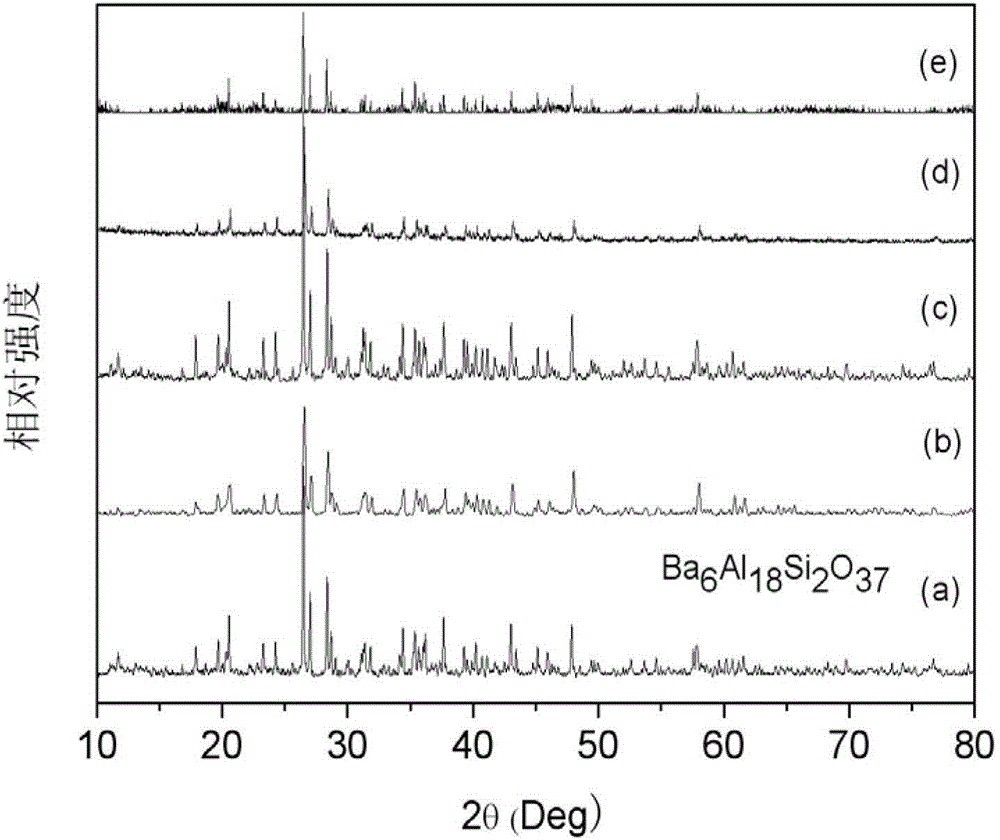

[0058] Carry out X-ray diffraction analysis to the sample that embodiment 1 obtains, instrument used is German Bruker / D8-FOCUS X-Ray Diffractometer, and radiation source is Cu Kα1 (λ=1.5405nm), scanning range: 2θ=10 °-80 ° , scan speed 10° / min. figure 1 For the XRD diffraction pattern of the red fluorescent luminescent material prepared in em...

Embodiment 2

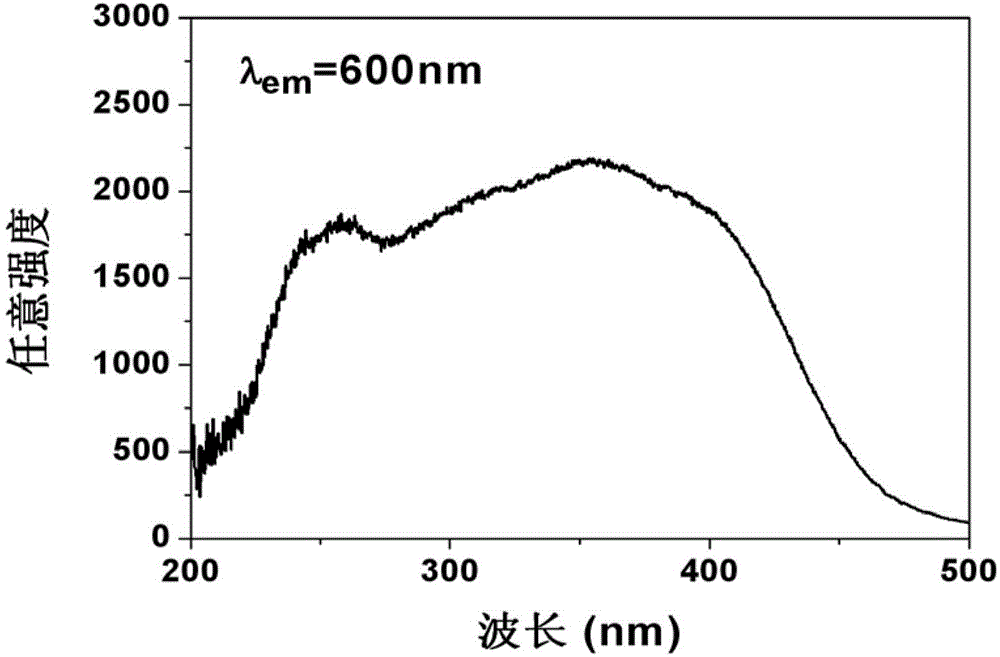

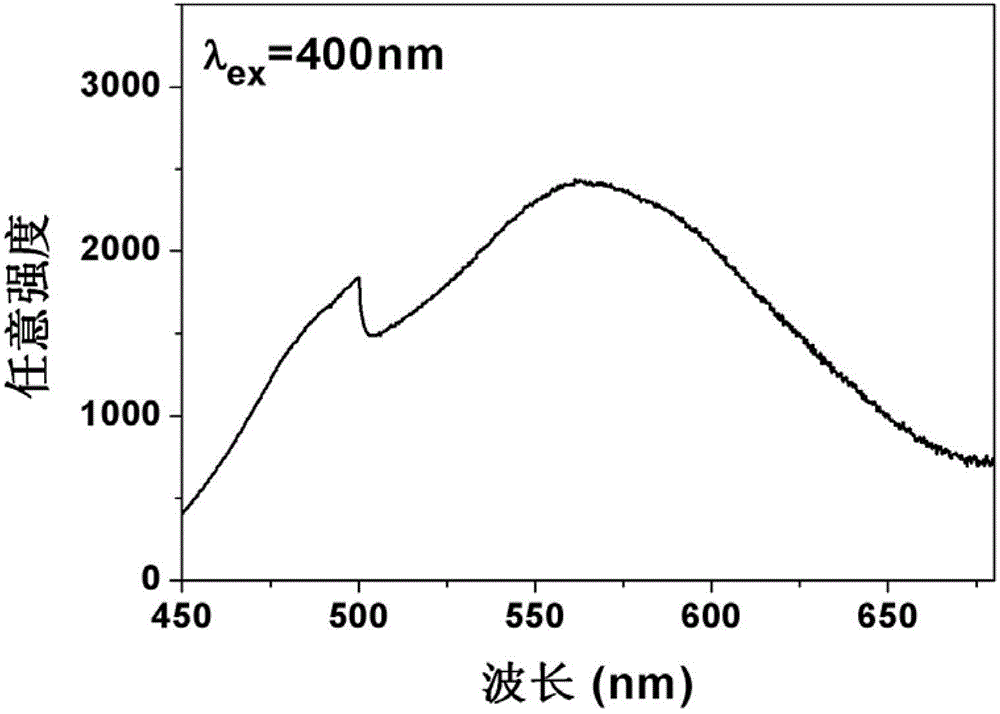

[0060] BaCO 3 (analytical pure), Al 2 o 3 (analytical pure), SiO 2 (analytical pure), Eu 2 o 3 (99.99%), with B 2 o 3 (Analytical pure) is the flux, and the molar ratio between them is 5.9998:9:2:0.0001:0.5. The above raw materials are accurately weighed, fully ground in an agate mortar, put into a corundum crucible, and then put into a large Fill a corundum crucible with carbon rods, put it into a high-temperature furnace and bake at 1350°C for 5 hours, cool it down to room temperature naturally, take it out and grind it, and then you can get a light yellow powder sample, the actual composition is Ba 5.9998 Eu 0.0002 Al 18 Si 2 o 37 . Its excitation peak is as figure 2 As shown, its emission spectrum is broadband emission, and the maximum emission wavelength is located near 600nm. The sample is exposed to sunlight for 10 minutes, and the sample emits a long red afterglow. After the test of the ST-86LA screen luminance meter, the afterglow time can last for about...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com