Metal complex liquid crystal polymer and preparation method thereof

A liquid crystal polymer and metal coordination technology, applied in the field of polymer chemistry, can solve the problems of non-volatility, difficulty, low fluorescence efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A metal-complexed liquid crystal polymer, the general structure of which is:

[0054]

[0055]

[0056] The preparation method of this compound is:

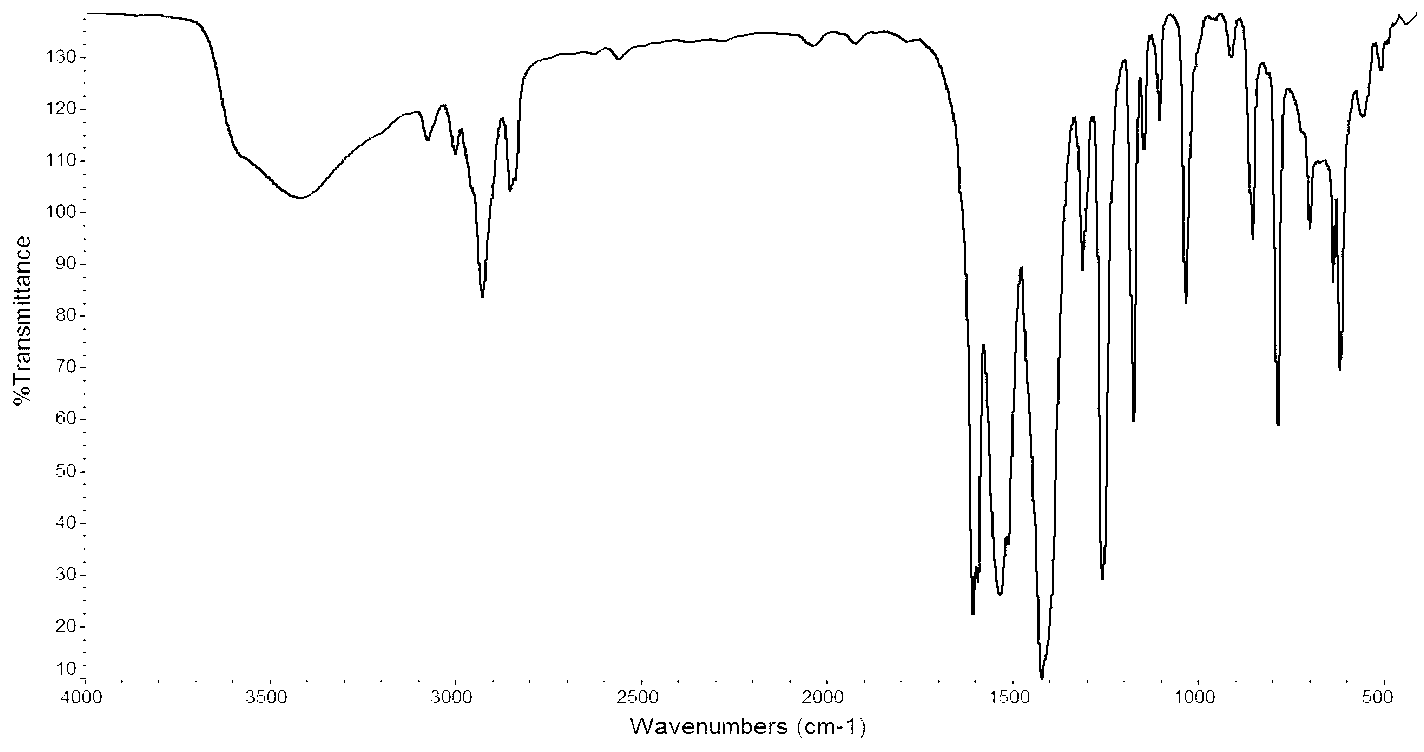

[0057] 4-(4-allyloxybenzoyloxy)-biphenoxyyl cholesteryl valerate (Ch) and allyloxybenzoic acid (I) and hydrogen-containing siloxane (PMHS) dissolved in toluene Among them, according to the molar ratio Ch: I: hydrogen-containing siloxane (PMHS): toluene is 50%: 50%: 10: 1, 50 ℃ constant temperature 4h, add the Pt / C catalyst of 8% of the total mass of reactants, React at 80°C for 24h. Monitor the reaction process with an infrared spectrometer, when the Si-H bond in PMHS is at 2166cm -1 The reaction was considered complete when the stretching vibration peak at the point disappeared completely. The reaction mixture was poured into methanol for precipitation and filtered with suction. The filter cake is washed with hot ethanol to remove unreacted monomers, and dried to obtain liquid crystal ionomer products.

[0058]...

Embodiment 2

[0067] A metal-complexed liquid crystal polymer, the general structure of which is:

[0068]

[0069] R 2 for

[0070] The preparation method of this compound is:

[0071] Menthyl 4-allyloxybenzoate (Ch) and allyloxybenzoic acid (I) and hydrogen-containing siloxane (PMHS) are dissolved in xylene, wherein according to the molar ratio Ch: I: hydrogen-containing Siloxane (PMHS):Xylene is 99.9%:0.1%:1:6, constant temperature at 100°C for 2.5h, add catalyst Pd / C catalyst with 0.05% of the total mass of reactants, and react at 130°C for 72h. The reaction process was monitored by an infrared spectrometer. When the stretching vibration peak of the Si-H bond in PMHS at 2166cm-1 completely disappeared, the reaction was considered complete. The reaction mixture was poured into methanol for precipitation and filtered with suction. The filter cake is washed with hot ethanol to remove unreacted monomers, and dried to obtain liquid crystal ionomer products.

[0072] In a 100mL sing...

Embodiment 3

[0080] A metal-complexed liquid crystal polymer, the general structure of which is:

[0081]

[0082] R 3 for

[0083] Cholesteryl 4-allyloxybenzoate (Ch) and allyloxybenzoic acid (I) and hydrogen-containing siloxane (PMHS) are dissolved in toluene according to the molar ratio Ch:I:hydrogen-containing siloxane Alkanes (PMHS): toluene ratio 20%: 80%: 1: 30, constant temperature at 90°C for 1h, add hexachloroplatinic acid catalyst with 2.2% of the total mass of reactants, and react at 15°C for 18h. The reaction process was monitored by an infrared spectrometer. When the stretching vibration peak of the Si-H bond in PMHS at 2166cm-1 completely disappeared, the reaction was considered complete. The reaction mixture was poured into methanol for precipitation and filtered with suction. The filter cake is washed with hot ethanol to remove unreacted monomers, and dried to obtain liquid crystal ionomer products.

[0084] In a 100mL single-necked bottle, the metal chloride salt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com