Processing method of rolling mill archway

A processing method and rolling mill archway technology, which is applied in the field of rolling mill archway processing, can solve the problems of long plum blossom hole length, time-consuming, scrapping of archway substrate, etc., and achieve the effect of zero scrapping rate and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

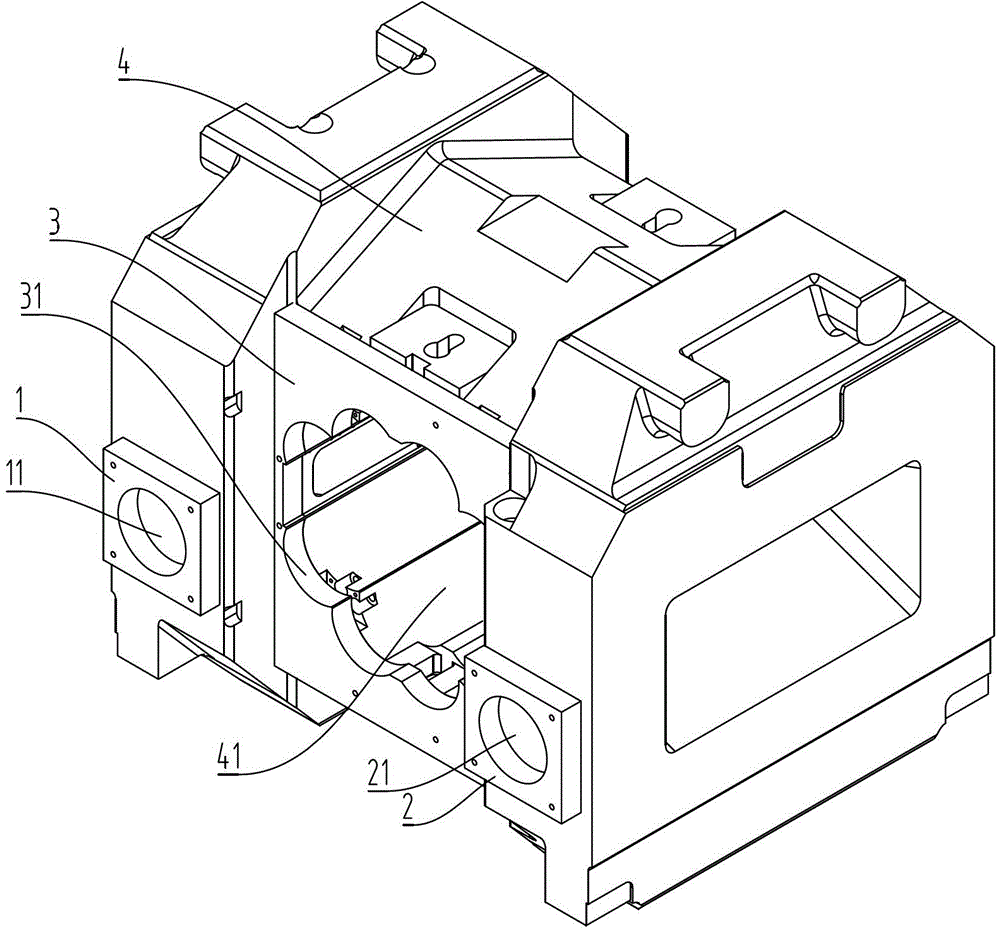

Image

Examples

Embodiment 1

[0034] When cutting, keep the ambient temperature at 25°C and keep the arch base temperature constant. The speed of the machine tool is 1500rpm, and the cutting is divided into multiple times. When the cutting radius is 260-320mm, the first cutting radius is 260mm. From the second cutting, each cutting radius is increased by 5mm compared with the previous cutting until the cutting radius reaches 320mm. ; η 2 The value is 0.05.

[0035] When the cutting radius is 320-350mm, each cutting radius increases by 1mm relative to the previous cutting, η 2 The value is 0.06.

[0036] When the cutting radius is 350-355mm, each cutting radius is increased by 0.5mm compared with the previous cutting, η 2 The value is 0.07

[0037] When the cutting radius is 355-360mm, each cutting radius is increased by 0.1mm compared with the previous cutting, η 2 The value is 0.08.

Embodiment 2

[0039]When cutting, keep the ambient temperature at 20°C and keep the temperature of the arch base constant. The speed of the machine tool is 2000rpm, and the cutting is divided into multiple times. When the cutting radius is 260-320mm, the first cutting radius is 260mm. From the second cutting, each cutting radius is increased by 3mm compared with the previous cutting until the cutting radius reaches 320mm. ; η 2 The value is 0.06.

[0040] When the cutting radius is 320-350mm, each cutting radius increases by 0.8mm compared with the previous cutting, η 2 The value is 0.065.

[0041] When the cutting radius is 350-355mm, each cutting radius increases by 0.4mm compared with the previous cutting, η 2 The value is 0.75

[0042] When the cutting radius is 355-360mm, each cutting radius increases by 0.08mm compared to the previous cutting, η 2 The value is 0.08.

Embodiment 3

[0044] When cutting, keep the ambient temperature at 22°C, and keep the arch base temperature constant. The speed of the machine tool is 2500rpm, and the cutting is divided into multiple times. When the cutting radius is 260-320mm, the first cutting radius is 260mm. From the second cutting, each cutting radius is increased by 4mm compared with the previous cutting until the cutting radius reaches 320mm. ; η 2 The value is 0.065.

[0045] When the cutting radius is 320-350mm, each cutting radius increases by 0.9mm compared with the previous cutting, η 2 The value is 0.07.

[0046] When the cutting radius is 350-355mm, each cutting radius is increased by 0.3mm compared with the previous cutting, η 2 The value is 0.75

[0047] When the cutting radius is 355-360mm, each cutting radius increases by 0.06mm compared with the previous cutting, η 2 The value is 0.08.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com