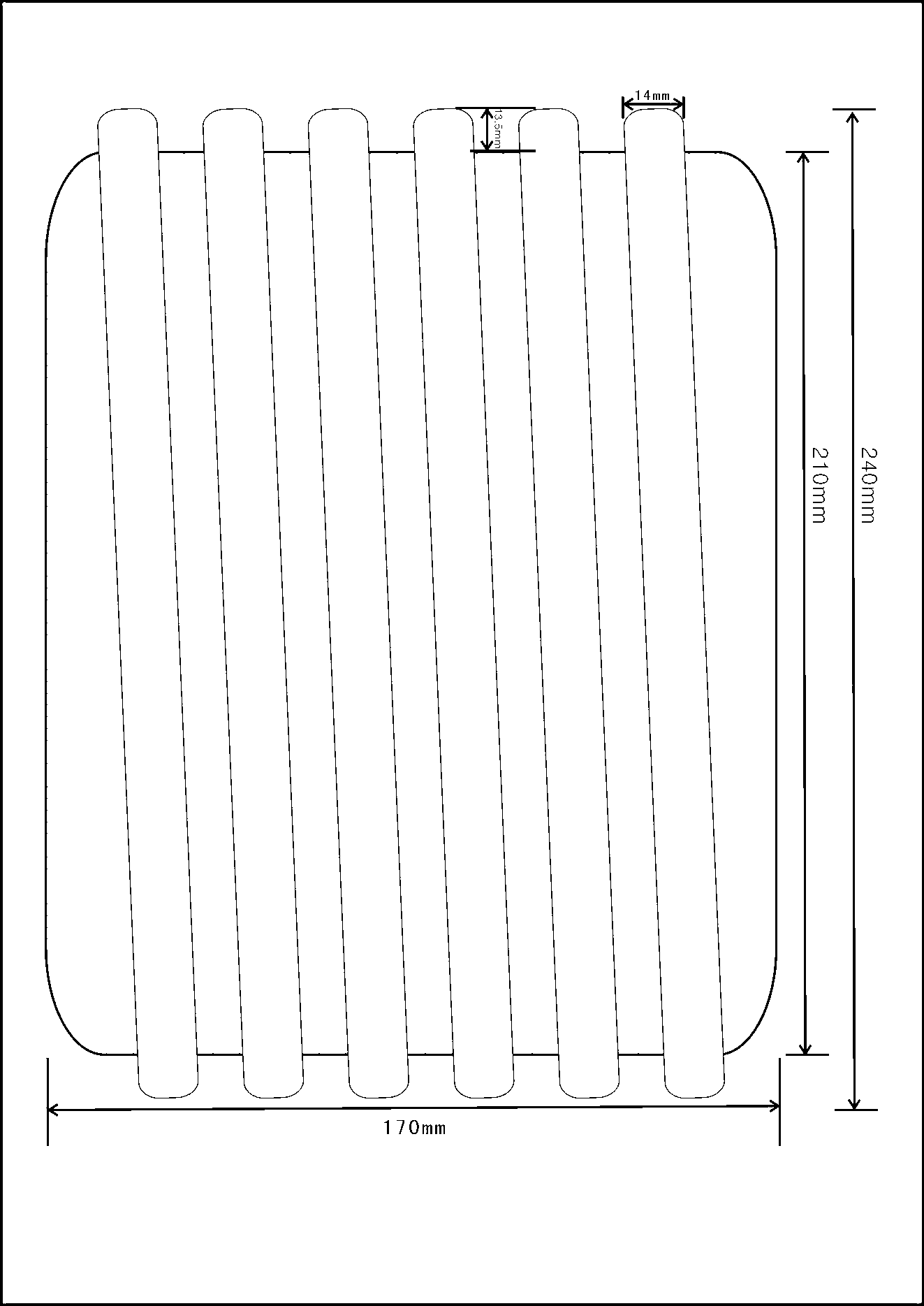

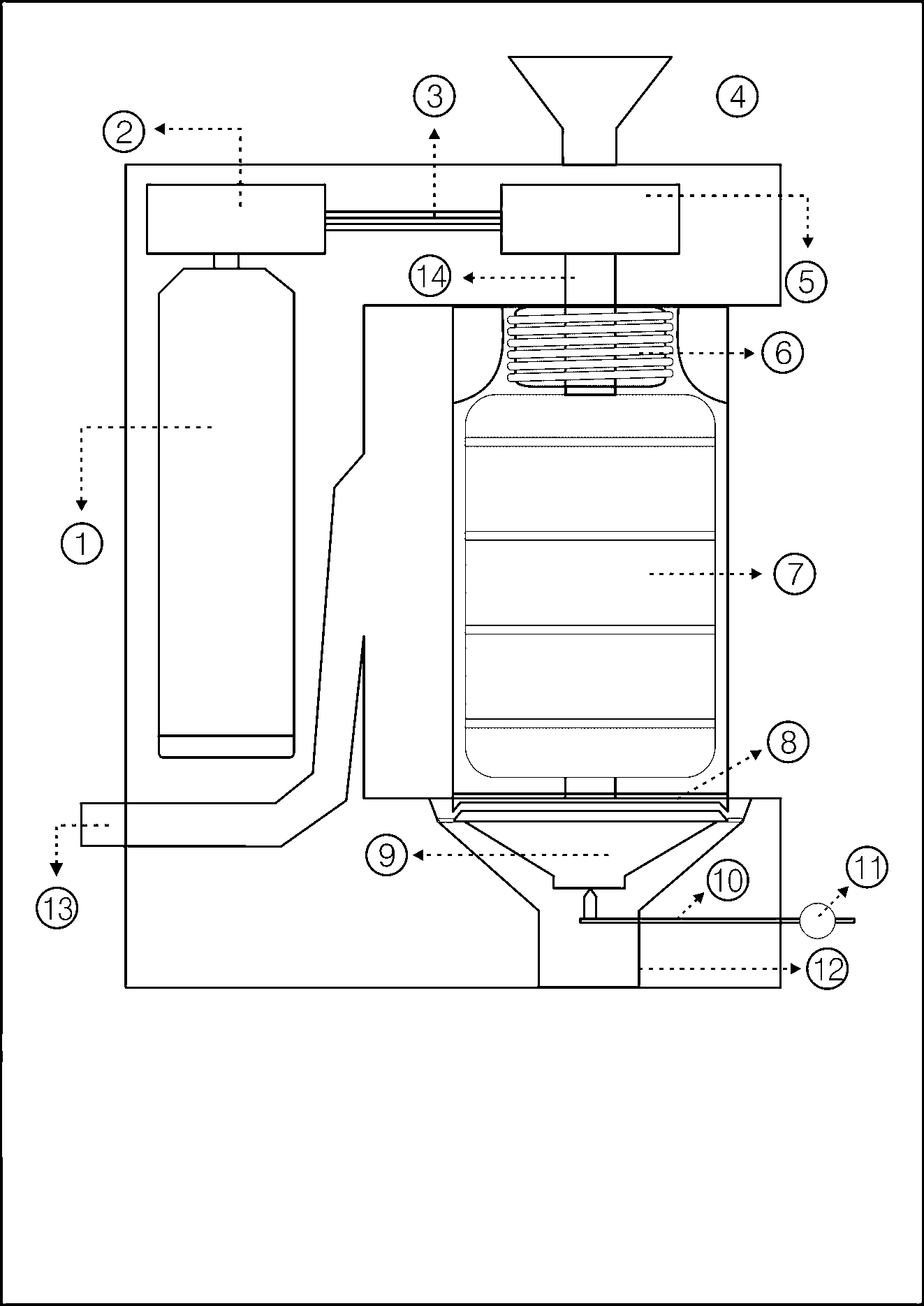

Method for processing milled rice with embryos and equipment thereof

A technology of germ rice and rice machine, which is applied in the direction of grain germ removal, grain processing, grain pod removal, etc., which can solve the problems of food waste, insufficient technology, and complicated processing methods and procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the present invention, the present invention will be described in detail below in conjunction with specific examples.

[0023] Grain sieve to magnetic separation is upgraded to grain air separator, and the grain air separator is upgraded to the first MNML25 rice machine, and the first emery roller speed is adjusted to 1120 rpm, and the rice machine exhaust fan Wind pressure adjustment 12 pa / cm 2 , The emery roller peels off the peel and seed coat of brown rice containing pesticide residues and grinds them. For example, before the adjustment of the operation process, the speed of the emery roller of the first rice machine is 980 rpm, and the air pressure of the rice machine exhaust fan is adjusted to 16-18 pa / cm 2 , When the rice grains are rough, remove 90% of the pericarp, seed coat, aleurone layer, and germ.

[0024] Elevate the rice grains ground and roughened by the first rice machine to the second MNML25 rice machine, adjust the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com