Anticorrosion smoke waste heat recycling device of heat pipe structure

A technology of a flue gas waste heat and recovery device, applied in the field of waste heat recovery heat pipes, can solve the problems of increasing flow resistance, affecting the safe operation of equipment, affecting heat transfer effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

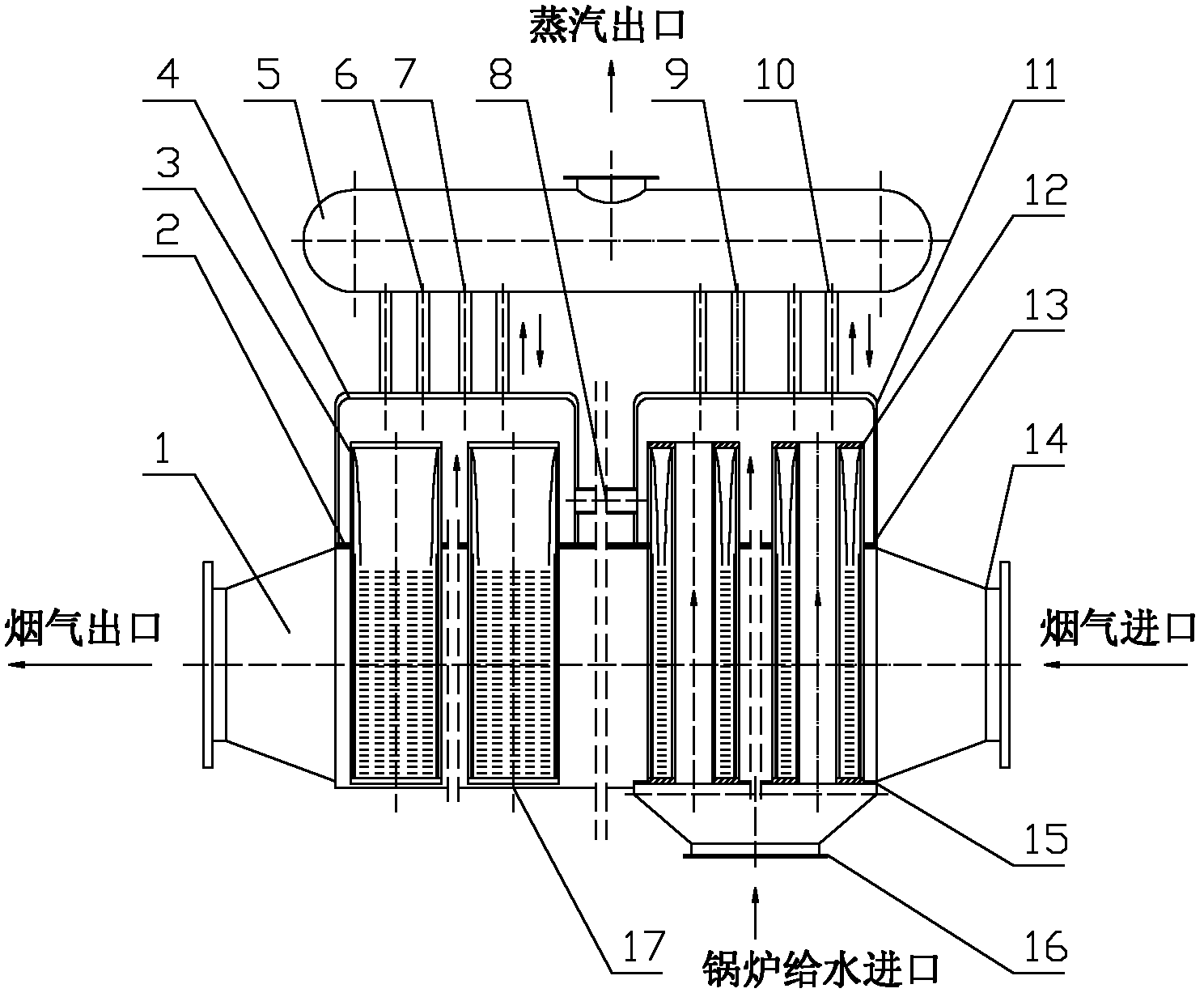

[0027] A corrosion-resistant flue gas waste heat recovery device with a heat pipe structure of the present invention adopts a sleeve-type heat pipe structure in the primary steam generator, which changes the cold water circulation path and form of the existing heat exchanger.

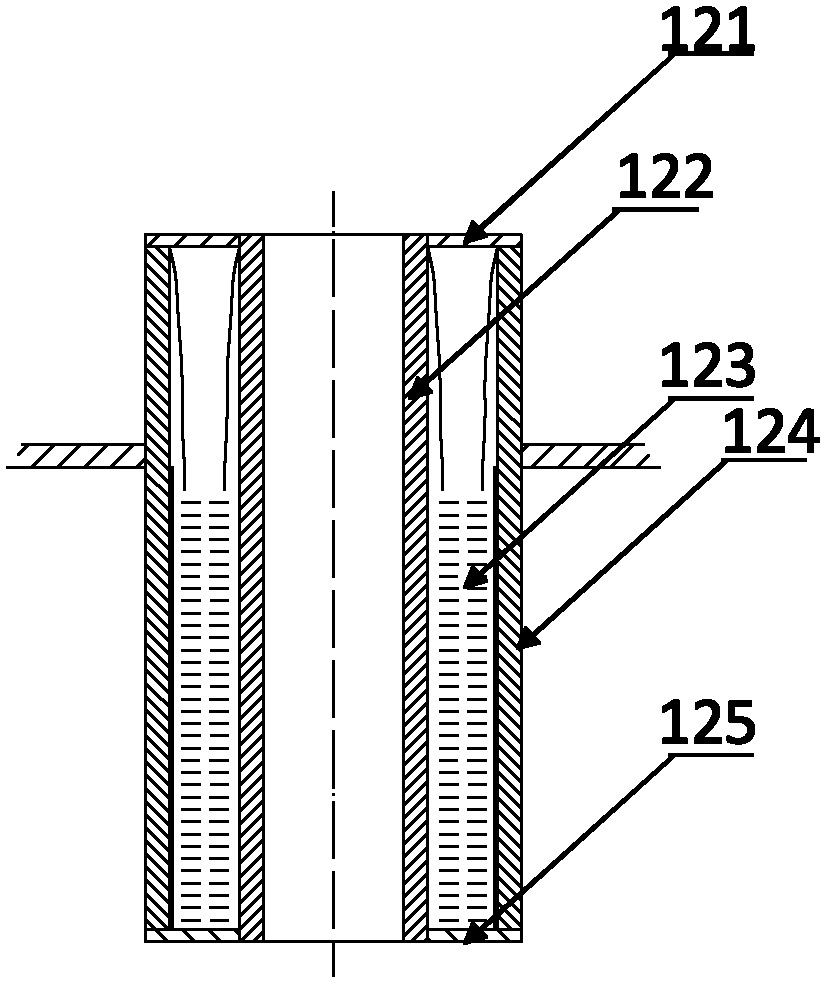

[0028] like figure 1 As shown, it is a corrosion-resistant flue gas waste heat recovery device with a heat pipe structure. The primary steam generator 11 is composed of tube bundles of sleeve-type heat pipes 12; the secondary steam generator 4 is composed of traditional heat pipes 3, and the middle partition 2 and 13. The secondary steam generator and the primary steam generator are divided into two parts respectively, and the connecting pipe 8 is used to communicate between the two parts. The gas-gathering generating chamber on the upper part of the partition is connected to the steam-gathering drum 5 by ascending pipes 7 and 10 and descending pipes 6 and 9; The tube flows into the steam generating ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com