A kind of production method of colored superfine denier polyester pre-oriented yarn

A technology of ultra-fine denier polyester and pre-oriented yarns, which is applied in the melting of filament raw materials, the bundling of newly extruded yarns, and the melt spinning method, which can solve the problems of large energy consumption, energy consumption, and pollution, and achieve Full color range, high product quality, good air permeability and warmth retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

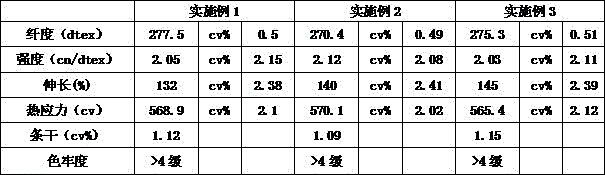

Embodiment 1

[0033] A kind of production method of colored superfine denier polyester pre-oriented yarn, described production method comprises the steps:

[0034] a) Pre-crystallize and dry polyethylene terephthalate and polyester color masterbatch respectively; among them, the pre-crystallization and drying temperature of polyethylene terephthalate are both 175°C, and the moisture content after drying is 25ppm , the pre-crystallization time is 20min, and the drying time is 6h; the pre-crystallization and drying temperature of polyester color masterbatch are both 100°C, the moisture content after drying is 100ppm, the pre-crystallization time is 10min, and the drying time is 4h; polyethylene terephthalic acid The intrinsic viscosity of ethylene glycol is 0.6dl / g; 5kg of polyester color masterbatch is used for every 100kg of polyethylene terephthalate;

[0035] b) Melt the polyethylene terephthalate and polyester color masterbatch obtained in step a) in a screw extruder at a temperature of ...

Embodiment 2

[0040]A kind of production method of colored superfine denier polyester pre-oriented yarn, described production method comprises the steps:

[0041] a) Pre-crystallize and dry polyethylene terephthalate and polyester color masterbatch respectively; among them, the pre-crystallization and drying temperature of polyethylene terephthalate are both 180°C, and the moisture content after drying is 20ppm , the pre-crystallization time is 30min, and the drying time is 7h; the pre-crystallization and drying temperature of polyester color masterbatch is 110°C, the moisture content after drying is 90ppm, the pre-crystallization time is 15min, and the drying time is 5h; Polyterephthalic acid The intrinsic viscosity of ethylene glycol is 0.62dl / g; 6kg of polyester color masterbatch is used for every 100kg of polyethylene terephthalate;

[0042] b) Melt the polyethylene terephthalate and polyester color masterbatch obtained in step a) in a screw extruder at a temperature of 280°C to obtain ...

Embodiment 3

[0047] A kind of production method of colored superfine denier polyester pre-oriented yarn, described production method comprises the steps:

[0048] a) Pre-crystallize and dry polyethylene terephthalate and polyester color masterbatch respectively; among them, the pre-crystallization and drying temperature of polyethylene terephthalate are both 185°C, and the moisture content after drying is 15ppm , the pre-crystallization time is 40min, and the drying time is 8h; the pre-crystallization and drying temperature of polyester color masterbatch are both 120°C, the moisture content after drying is 60ppm, the pre-crystallization time is 20min, and the drying time is 6h; polyethylene terephthalic acid The intrinsic viscosity of ethylene glycol is 0.65dl / g; 8kg of polyester color masterbatch is used for every 100kg of polyethylene terephthalate;

[0049] b) Melt the polyethylene terephthalate and polyester color masterbatch obtained in step a) in a screw extruder at a temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com