Thermal treatment method of spline shaft head of transmission shaft

A heat treatment method and spline shaft technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of short fatigue life of workpieces, short fatigue life, increased heat treatment costs, etc., and achieve the expansion of induction heating and quenching area, strength and toughness Improve and enhance the effect of product competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

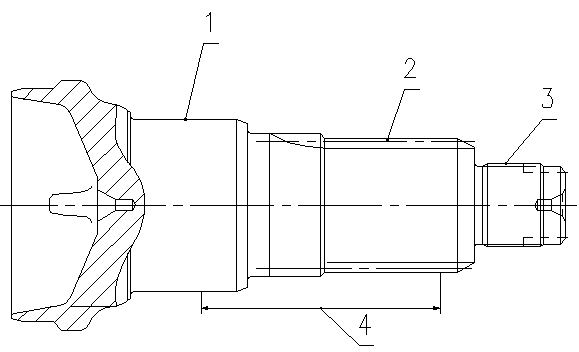

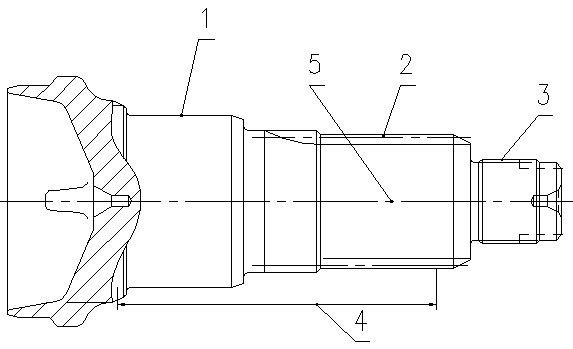

[0018] Such as figure 2 and figure 1 As shown, the spline shaft head includes an oil seal platform 1, a spline part 2 and a connecting screw head 3.

[0019] The heat treatment method of the transmission shaft spline shaft head of the present invention includes a normalizing process and an intermediate frequency induction hardening process in sequence.

[0020] The normalizing process includes two steps in sequence. The first step is to use a push-plate heating furnace (commonly used equipment in this field) to heat the spline shaft head at a heating temperature of 850°C±10°C for 120 minutes; the second step is to air-cool (i.e. air cooling) 2-3 hours, the temperature of the spline shaft head drops to room temperature after air cooling.

[0021] The intermediate frequency induction hardening process includes two steps. The first step is the quenching step. This step is to use the induction numerical control surface hardening machine tool (commonly used equipment in this fie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com