Graphene nonstick paint

A non-stick coating and graphene technology, applied in the direction of coating, etc., can solve the problems of poor thermal conductivity and high energy consumption, and achieve the effect of improving thermal conductivity, high hardness, and good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Adopt 1000g of commercial water-based PTFE non-stick coating (model is DuPont TE3809), add 20g graphene water-based slurry (commercially available, graphene content 5%, Ningbo Moxi Technology Co., Ltd.), and place it in a high-speed disperser Stir for 30 minutes until it is evenly mixed to obtain a graphene non-stick coating, and add a certain amount of water to adjust the viscosity to 20 mPa·s.

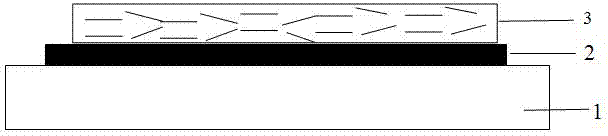

[0032] Using Shenzhen Xinyue Chemical Material Co., Ltd. XY-P200 as the primer, sprayed on the 22cm diameter aluminum pot 1 after sandblasting and cleaning pretreatment, and cured at 100°C for 10 minutes to obtain a 5 micron primer layer 2 aluminum pans.

[0033] The graphene non-stick coating is obtained as the top coat in this embodiment, sprayed on the primer, baked at 100°C for 10 minutes, and then heated to 400°C for 10 minutes, to form a non-stick coating 3 on the surface of the primer to obtain the entire inner surface Aluminum pan covered with non-stick coating, the thickn...

Embodiment 2

[0035] Use 1000g of commercial water-based PTFE non-stick coating (model Daikin D210C), add 1000g of graphene water-based slurry (commercially available, graphene content 5%, Ningbo Moxi Technology Co., Ltd.), and place it in a high-speed dispersion machine Stir for 30 minutes until it is evenly mixed to obtain a graphene non-stick coating, and add a certain amount of water to adjust the viscosity to 20 mPa·s.

[0036] Shenzhen Xinyue Chemical Material Co., Ltd. XY-P200 was used as the primer, sprayed on a 22cm diameter aluminum pan after sandblasting and cleaning pretreatment, and cured at 100°C for 10 minutes to prepare aluminum coated with a 5 micron primer pot.

[0037] The graphene non-stick coating was obtained as the top coat in this example, sprayed on the primer, baked at 100°C for 10 minutes, heated to 400°C for 10 minutes, and sintered to form a non-stick coating on the surface of the primer, so that the inner surface was completely covered For aluminum pans with non-st...

Embodiment 3

[0039] Use 1000g of commercial water-based PTFE non-stick coating (model Daikin D210C), add 100g of graphene water-based slurry (commercially available, graphene content 5%, Ningbo Moxi Technology Co., Ltd.), and place it in a high-speed disperser Stir for 30 minutes until the mixture is uniform to obtain a graphene non-stick coating, and add a certain amount of water to adjust the viscosity to 30 mPa·s.

[0040] Shenzhen Xinyue Chemical Material Co., Ltd. XY-P200 was used as the primer, sprayed on a 22cm diameter aluminum pan after sandblasting and cleaning pretreatment, and cured at 100°C for 10 minutes to prepare aluminum coated with a 5 micron primer pot.

[0041] The graphene non-stick coating was obtained as the top coat in this example, sprayed on the primer, baked at 100°C for 10 minutes, heated to 400°C for 10 minutes, and sintered to form a non-stick coating on the surface of the primer, so that the inner surface was completely covered For aluminum pans with non-stick co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com