Polymerization method of polytetrahydrofuran single alcohol and diol mixture

A technology of polytetrahydrofuran monoalcohol and polymerization method, which is applied in the direction of chemical recovery, etc., can solve the problems of long process, poor stability and adjustability, etc., and achieve the effect of short process, good stability and adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

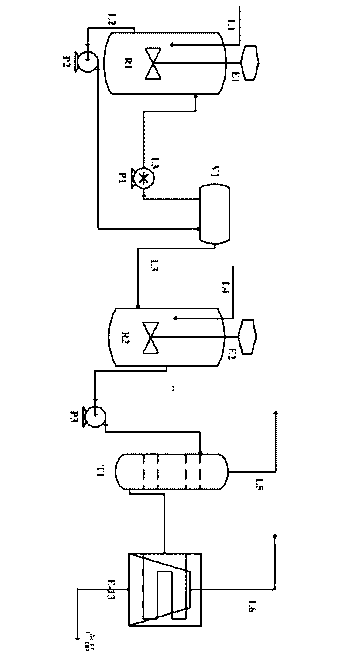

[0048] Embodiment: a kind of polymerization method of polytetrahydrofuran monoalcohol and diol mixture of this example, as figure 1As shown, its methods include:

[0049] a. Prepare a 2L three-necked round-bottomed flask, add heteropolyacid 350g (in this example, the crystal water content of heteropolyacid is 9.5) that meets the requirements of the present invention, and add tetrahydrofuran solution 1000ml that meets the requirements of the present invention ( The water content of tetrahydrofuran in this example was less than 0.01%). Place the above-mentioned round-bottomed flask containing the heteropolyacid catalyst and tetrahydrofuran solution in a water bath at 65° C., one of the ports of the round-bottomed flask is connected to a condenser, and the middle port is connected to a stirrer. Another excuse to plug with a suitable stopper. Then turn on the stirrer and adjust the rotation speed to 350rpm, stop stirring after 2 hours and let it stand for 30min. The heteropoly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com