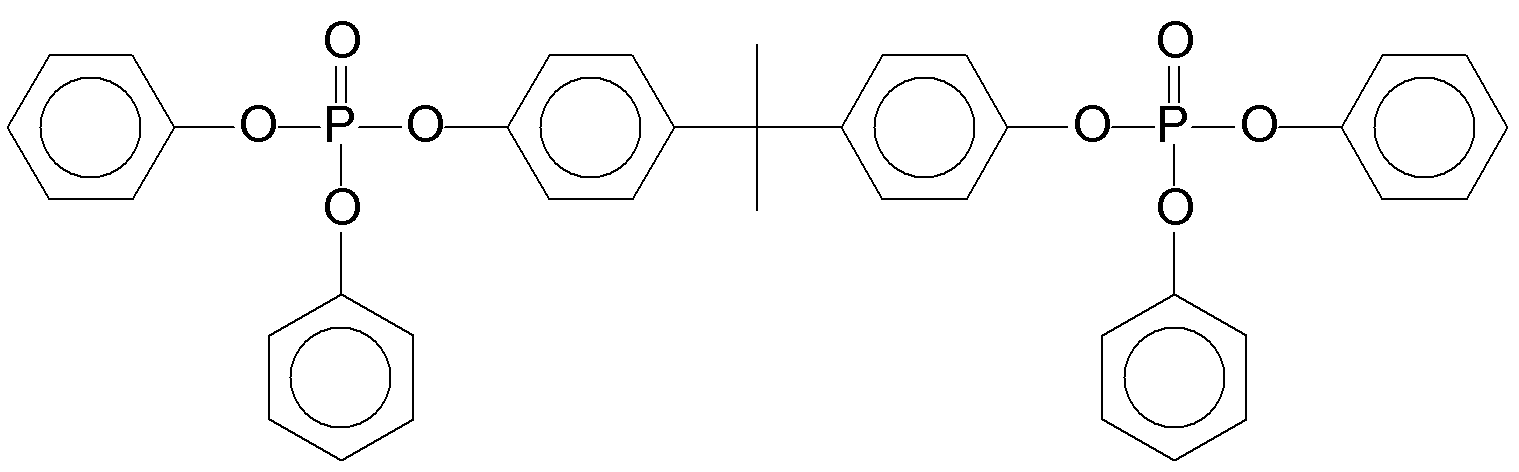

Preparation method of bisphenol A bis(diphenyl phosphate)

A technology of diphenyl phosphate and bisphenol, which is applied in the preparation of bisphenol A bis(diphenyl phosphate) and the field of bisphenol A bis(diphenyl phosphate), can solve the problem that the preparation method has many reaction steps, Production environment pollution, corrosion of equipment and other problems, to achieve the effect of short reaction time, increase economic benefits, and reduce waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0045] The reagents used in the present invention, unless otherwise specified, are commercially available conventional reagents; the methods used, unless otherwise specified, are conventional methods in the art.

[0046] The main raw material that the present invention uses:

[0047] BPA, phenol, phosphorus oxychloride, catalyst

[0048] The preparation steps of the catalyst used in the present invention are as follows:

[0049] (1) Mix HZSM-5 type molecular sieve, calcium sulfate, magnesium chloride, turmeric powder and water to obtain a mixed solution;

[0050] The mass ratio of HZSM-5 molecular sieve, calcium sulfate, magnesium chloride and sage powder to each 1L of mixed solution is 10:2.9:2.5:1;

[0051] (2) Under stirring conditions...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com