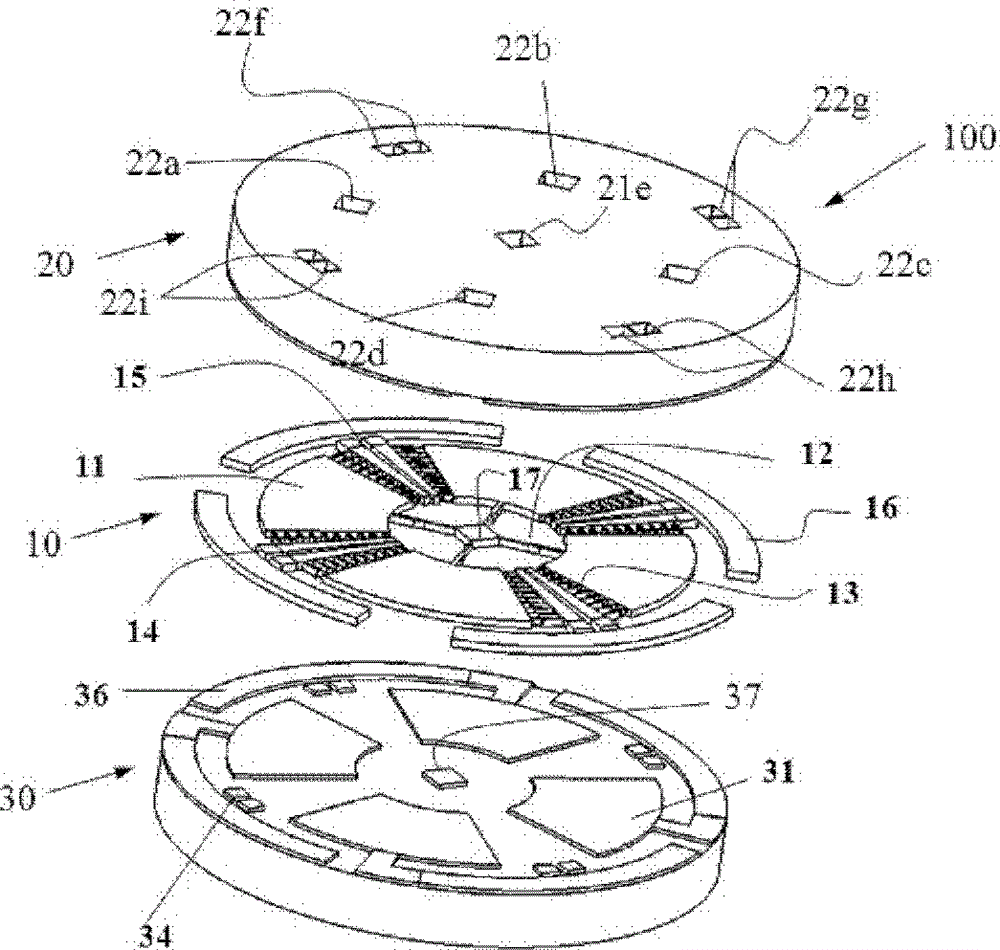

A processing method for a four-mass silicon micro-electromechanical gyro structure

A silicon microelectromechanical gyroscope and four-mass block technology are applied in microstructure technology, microstructure devices, manufacturing microstructure devices, etc., which can solve the problems of large residual stress, difficult to develop clean, metallization, etc., and improve the sidewall. Verticality, solving different thermal expansion coefficients, and ensuring the effect of line quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

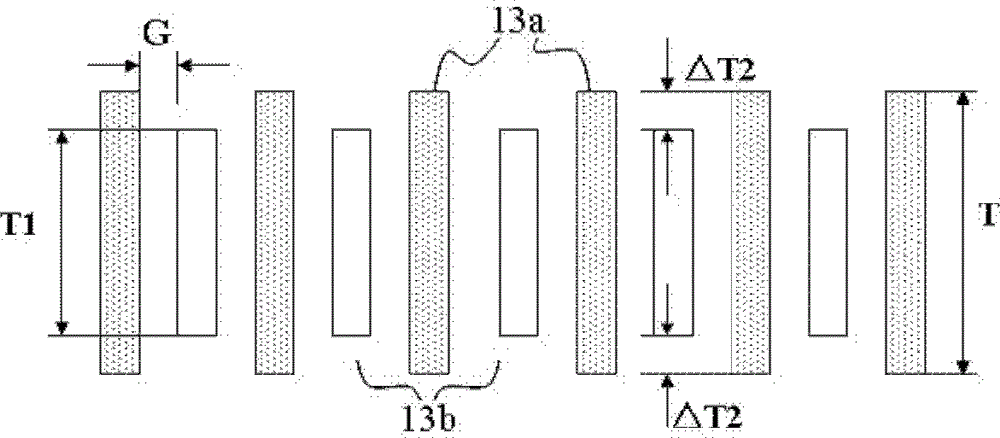

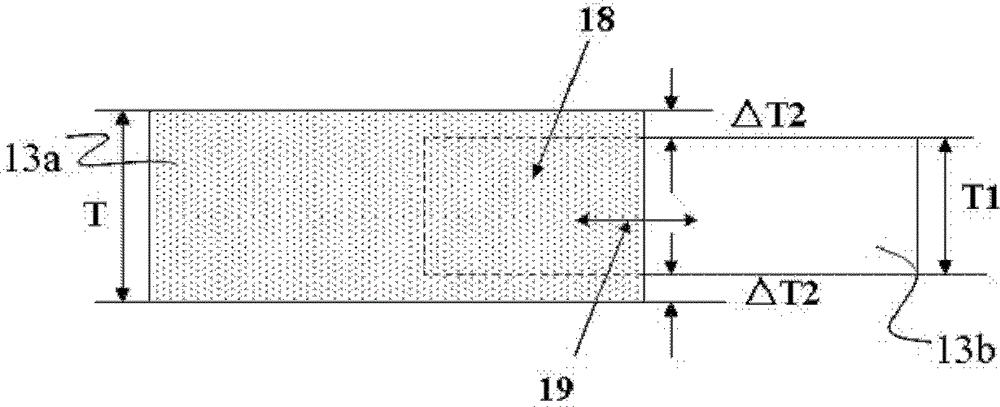

[0084] The specific implementation manner of the present invention will be described below according to the accompanying drawings.

[0085] A method for processing a four-mass silicon micro-electromechanical gyro structure, comprising the steps of:

[0086] Step 1: Process the lower cap

[0087] Step 1.1 Clean the lower capping substrate

[0088] as attached Figure 4 As shown, the SOI substrate is first cleaned before processing the lower cap, and the substrate includes a lower cap device layer 30a, a lower cap insulating layer 30b and a lower cap support layer 30c, wherein the lower cap device layer 30a is Si, P-type doping, (111) crystal orientation, thickness of 60-80 μm, lower sealing cap insulating layer 30b is SiO 2 , with a thickness of 1-2 μm, the lower sealing cap support layer 30c, p-type doped, (111) crystal orientation, with a thickness of 400-500 μm. The cleaning process is as follows: the first step is to use SC-1 (NH 4 OH:H 2 o 2 :H 2 (O=1:1:5, volume r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com