Electromagnetic controllable mechanical brake parking device

A mechanical braking and controllable technology, applied in the direction of brake transmission, brake, railway braking system, etc., can solve the problems of complex system, tread wear, crack or peeling, etc., to achieve simple device structure and small occupied space. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

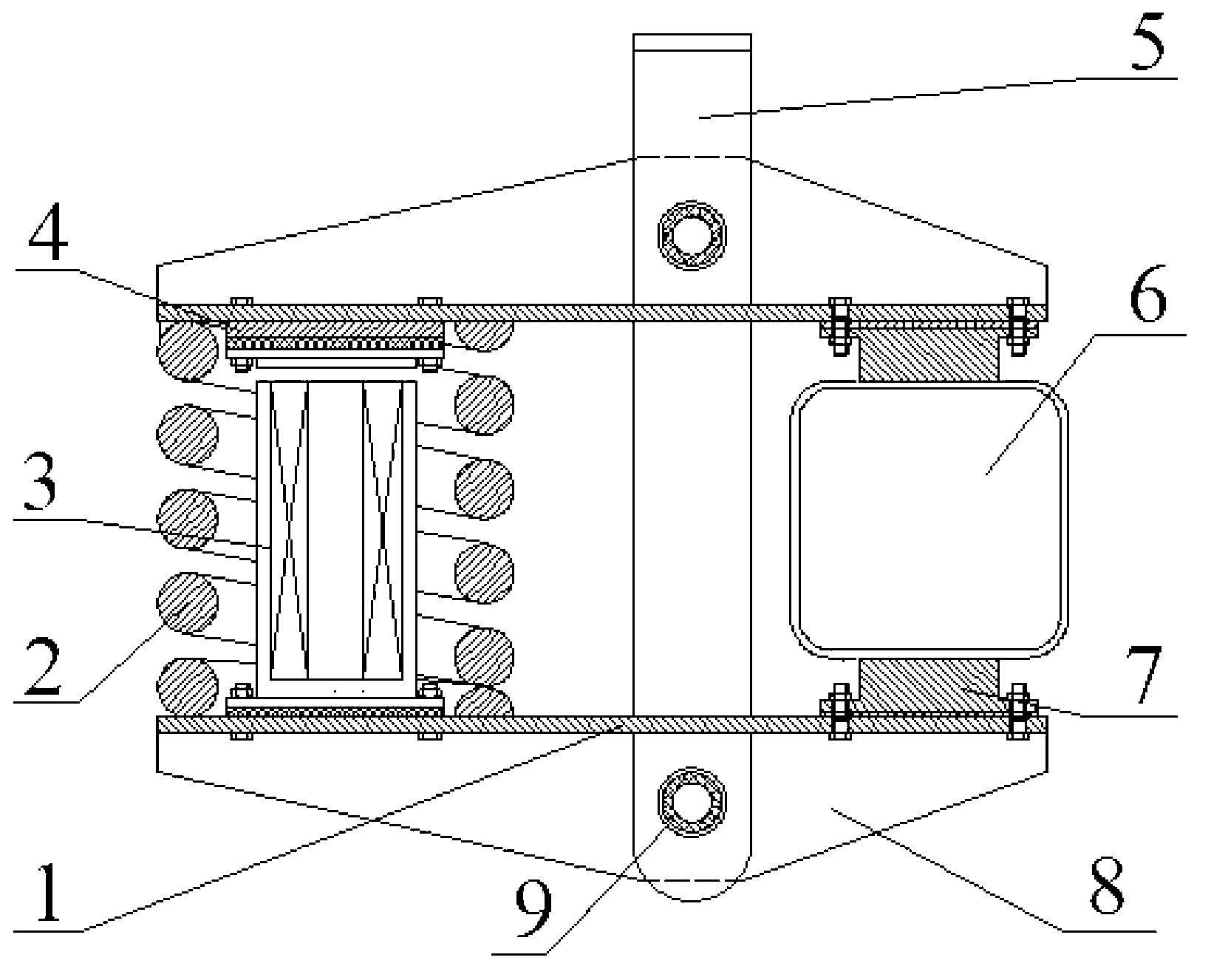

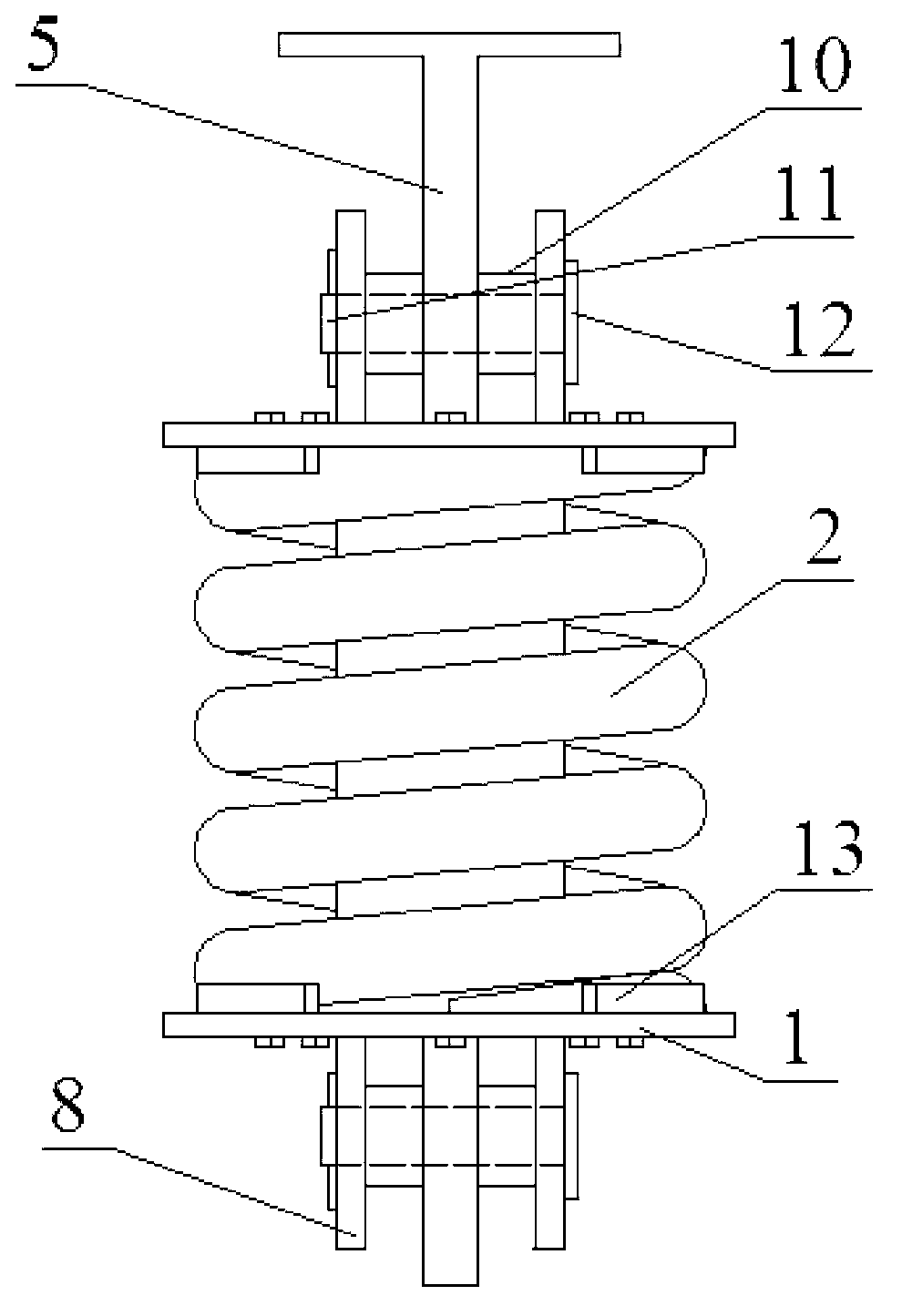

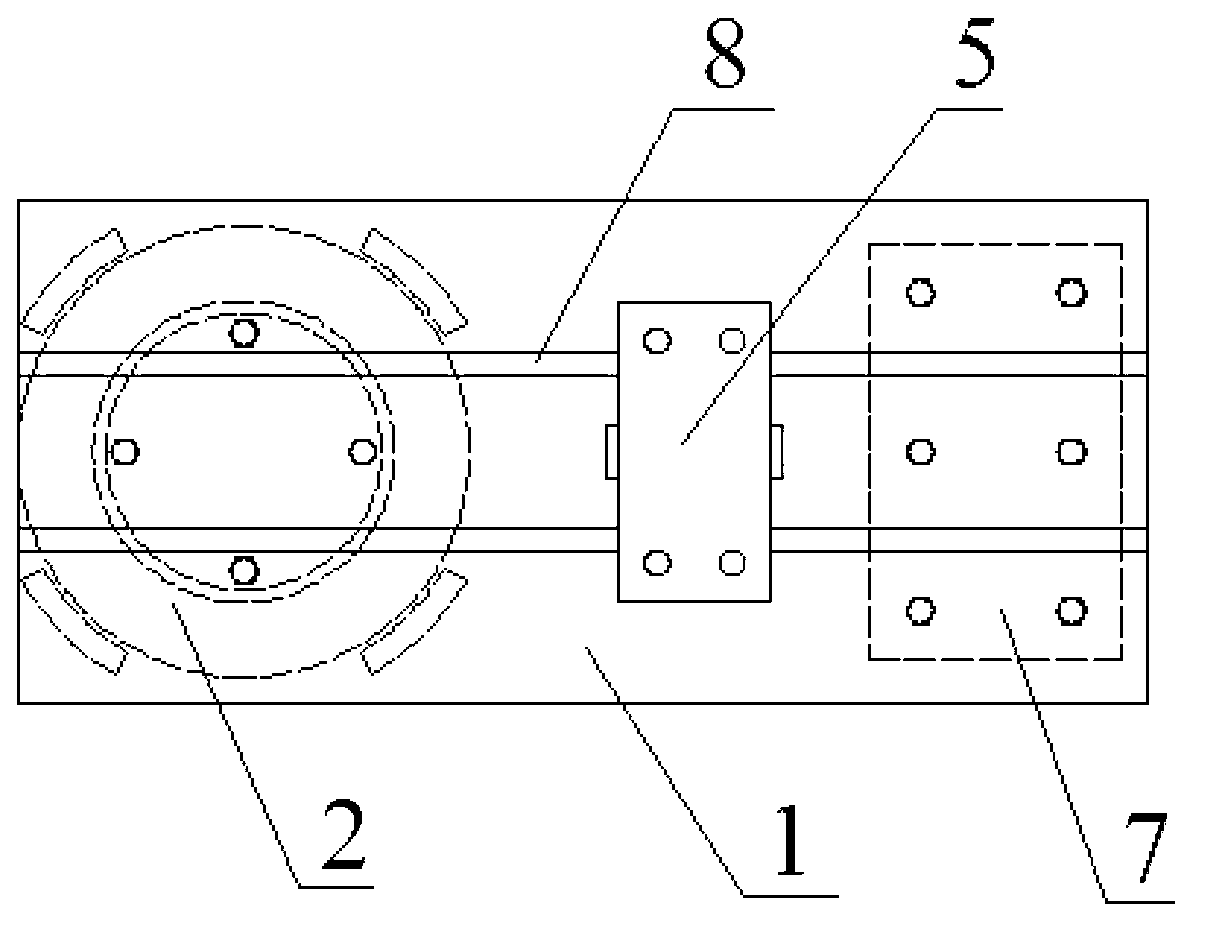

[0027] An electromagnetic controllable mechanical brake parking device, such as Figure 1 ~ Figure 3 As shown, it includes the action arm 1, the action arm mounting seat 5, the cylindrical compression spring 2, the electromagnet assembly 3 and the wear plate 7. There are two action arms 1, and two rib plates 8 are arranged on the action arm 1. One stiffener plate 8 is respectively positioned at the front and rear sides of the action arm mounting seat 5, and the upper and lower ends of the stiffening rib plate 8 and the action arm mounting seat 5 are rotationally connected by pin shaft 11. Both ends of pin shaft 11 are locked by tooth bar 12 . Both the rib plate 8 and the mounting seat 5 of the action arm are provided with mounting holes, and a bushing 9 is arranged in the mounting hole, and the pin shaft 11 is arranged in the bushing 9, and is located between the rib plate 8 and the mounting seat 5 of the action arm A positioning sleeve 10 is sheathed on the outer side of the...

Embodiment 2

[0032] The difference from Example 1 is:

[0033] The thickness of the adjusting gasket 4 is 5mm, the thickness of the magnetically insulating gasket is 2mm, and the diameter is 70mm, and the material of the magnetically insulating gasket is a non-magnetic material selected from lead or copper. The wear plate 7 has a length of 100mm and a width of 50mm.

[0034] Cylindrical compression spring 2 is made of 55Si2Mn steel wire with a diameter of 20mm. The middle diameter of cylindrical compression spring 2 is 100mm, the number of effective turns is 3, the stiffness is 500N / mm, and the free height is 120mm. The force is 1000N.

[0035]The electromagnet assembly 3 includes an armature and a series coil. The series coil is composed of a wire with a diameter of 3 mm wound around the armature. The diameter of the armature is 6 cm. The number of turns of the series coil is 100 turns. The magnetic potential of the series coil is 1000 ampere-turns. When a current of 0-20 A is connected...

Embodiment 3

[0037] The difference from Example 1 is:

[0038] The thickness of the adjusting washer 4 is 15mm, the thickness of the non-magnetic spacer is 5mm, and the diameter is 170mm, and the material of the non-magnetic spacer is a non-magnetic material selected from palladium alloy. The wear plate 7 has a length of 300mm and a width of 150mm. Cylindrical compression spring 2 is made of 60Si2Mn steel wire with a diameter of 40mm. The middle diameter of cylindrical compression spring 2 is 200mm, the number of effective turns is 6, the stiffness is 1500N / mm, and the free height is 140mm. The force is 8000N.

[0039] The electromagnet assembly 3 includes an armature and a series coil. The series coil is composed of a wire with a diameter of 5 mm wound around the armature. The diameter of the armature is 16 cm. The number of turns of the series coil is 250 turns. The magnetic potential of the series coil is 1500 ampere-turns. When a current of 0-20A is connected, the magnetic induction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Middle diameter | aaaaa | aaaaa |

| Stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com