Small press

A press, small-scale technology, applied in the direction of presses, stamping machines, manufacturing tools, etc., can solve the problems of discomfort, hindering chip removal in chip processing, poor synchronization performance, etc., and achieve the effect of good eccentric load performance and good synchronization performance

Active Publication Date: 2013-07-24

阮建辉

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For a single-power press, its synchronization performance is good, but its partial load performance is poor; while for a multi-power press, its partial load performance is slightly better, but its synchronization performance is poor

The existence of these defects greatly reduces the service performance and life of the existing small presses and their molds

Moreover, when the oil cylinder is installed on the top of the press, the workpiece is easily polluted by pressure oil or lubricating oil; and when the oil cylinder is installed in the lower center of the press, the oil cylinder will hinder the chip removal of chip processing, so it is not suitable for Chip processing station use

In addition, the thickness of the sheet metal parts processed by the home appliance production line is not thick, usually less than 0.6mm, and its requirements for driving power are not high. Using an oil cylinder that can provide a large driving power will waste capacity, which neither saves energy nor saves energy. Not environmentally friendly; it would be an excellent solution if a cylinder with relatively low pressure can be used to drive it by boosting force

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

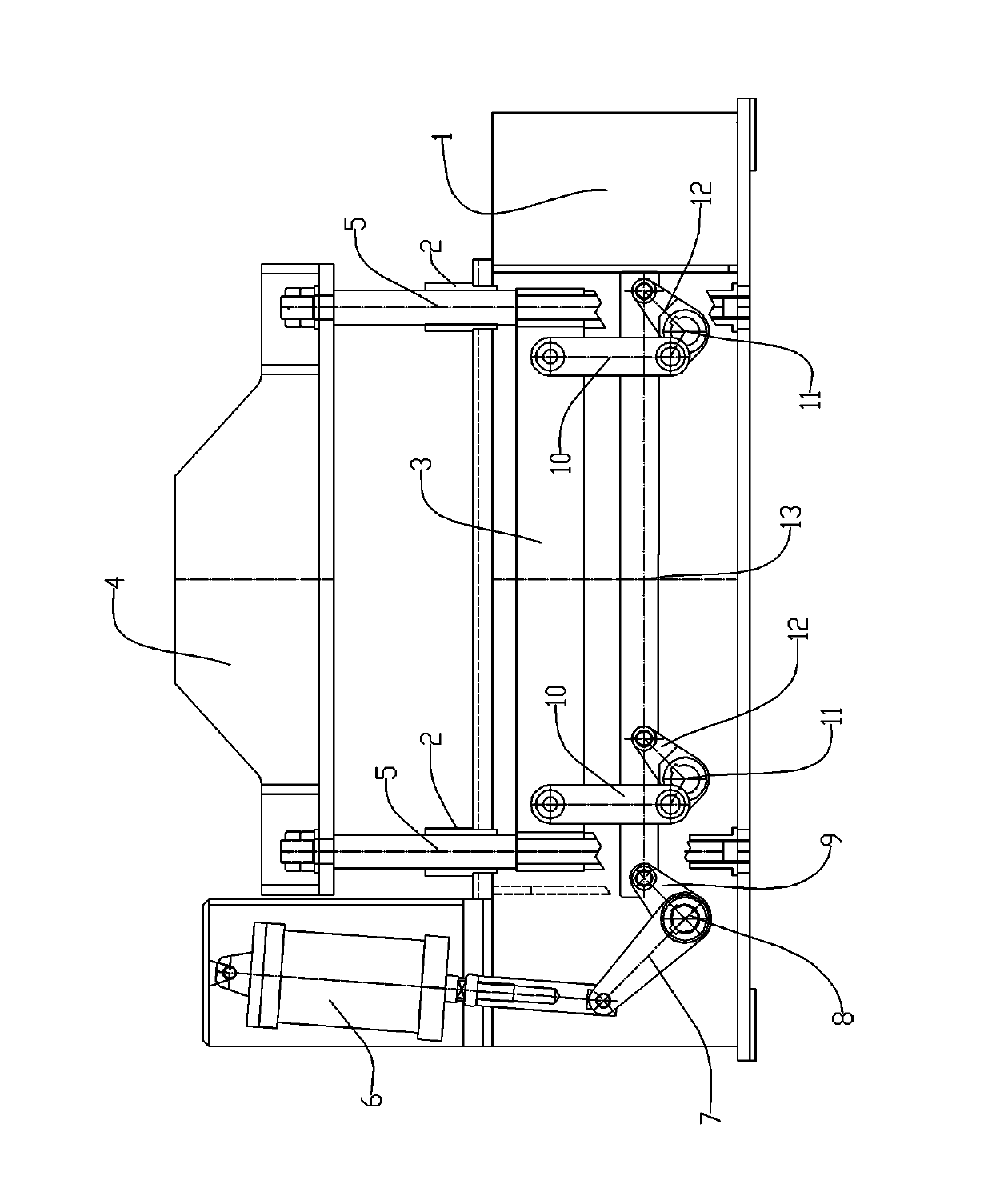

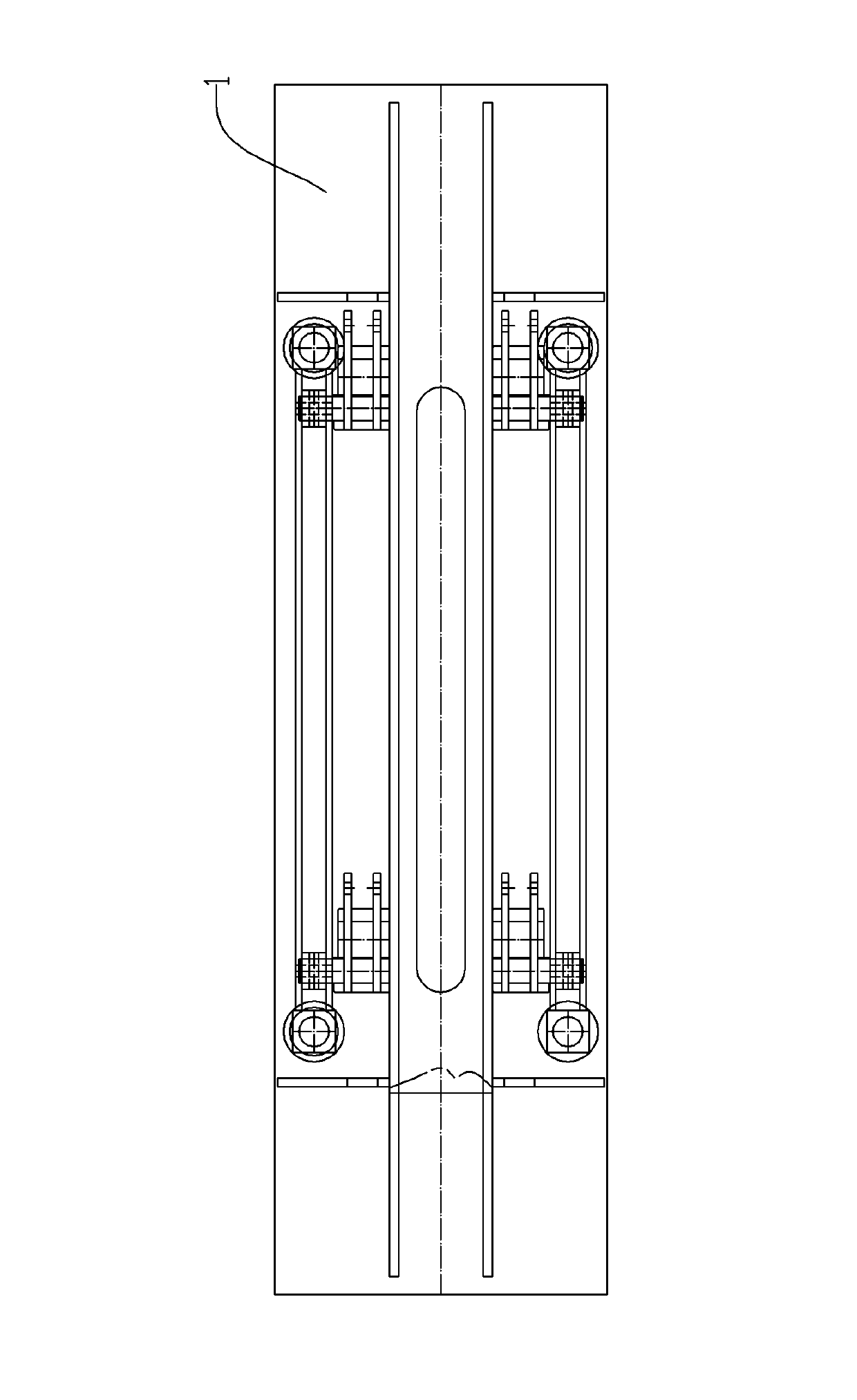

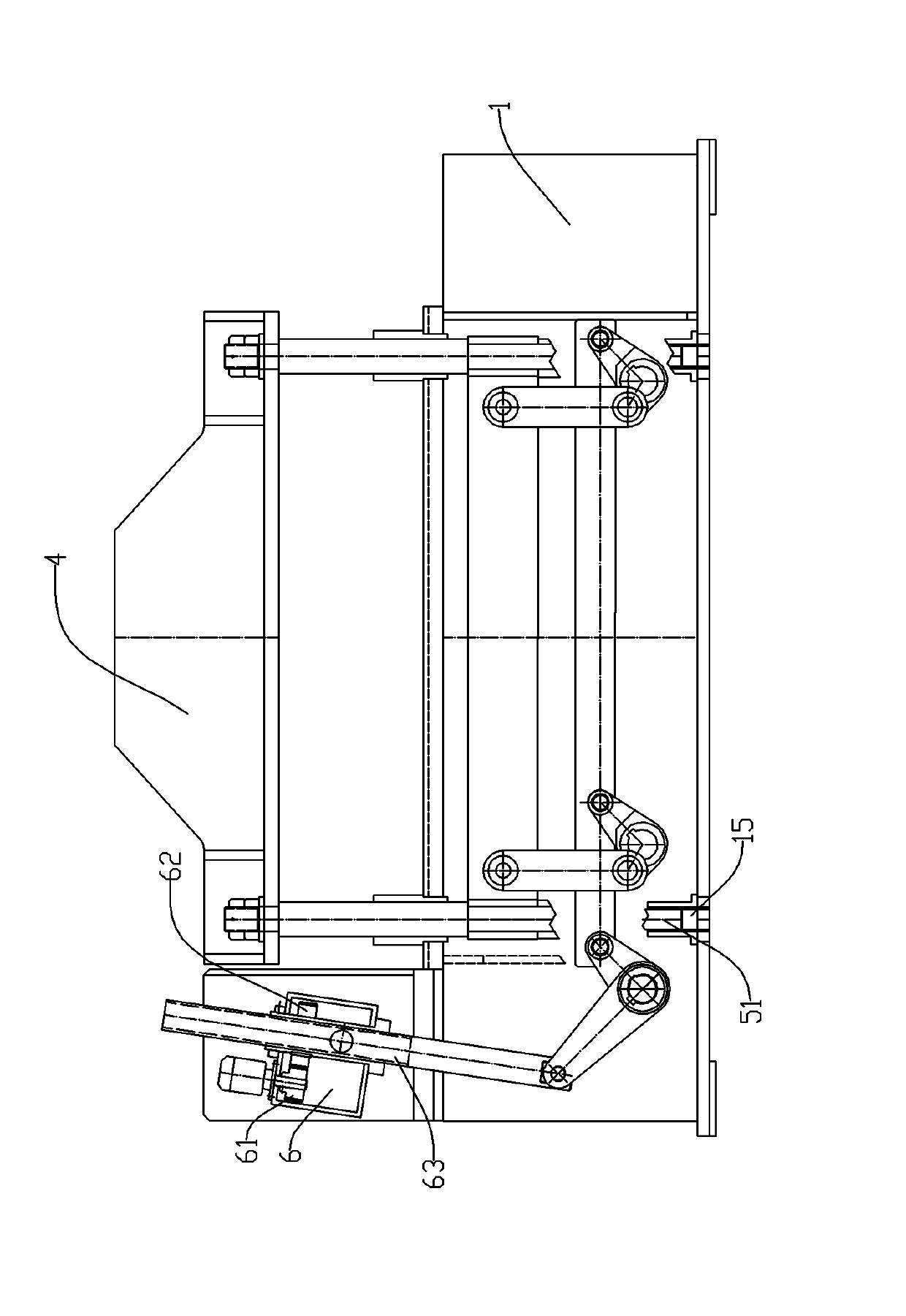

The invention discloses a small press, which is used for the stretching and punching shear operation and other types of punching and pressing processing on a household electrical appliance metal plate production line. The force application rod of the power element of the small press drives a main swing arm to swing; the main swing arm swings to rotate a torsion shaft and simultaneously drives auxiliary swing arms on the front side and the rear side to swing; the two auxiliary swing arms are used for simultaneously dragging a synchronizing bar to swing; the synchronizing bar swings to synchronously drag a crank to swing; then each crank synchronously dives respective draw bar; the draw bar drags a movable block; and the movable block pushes a guide pillar to slide relative to a guide sleeve to realize the lifting of a cross bar. Force and movement applied by the force application rod of the power element of the small press are synchronously transferred to four corner small presses on the upper cross beam in sequence by the main swing arm, the torsion shaft, the auxiliary swing arms, the synchronizing bar, the crank, the draw bar, the movable block and the guide pillar, four corners on the upper cross beam are dragged to synchronously move and apply pressure, and the small press disclosed by the invention has the advantages of good synchronization performance and strong unbalance loading resistance.

Description

technical field [0001] The invention relates to a processing machine for pressure forming, in particular to a small-sized press used for stretching, punching and shearing operations on sheet metal production lines of household appliances such as refrigerators and washing machines. Background technique [0002] Small presses are usually used in the sheet metal processing production lines of washing machines, air conditioners, refrigerators and other household appliances to provide power for stretching, stamping and shearing of sheet metal parts, and can also be used as a stand-alone machine. It is mainly composed of upper beam, movable beam, lower beam (or "workbench"), guide column, and oil cylinder; the upper beam is driven by the oil cylinder to apply pressure to realize the operation. It mainly has various forms such as single power and multi-power. For single-power presses, the oil cylinder is mostly set at the center of the top or bottom of the press; for multi-power ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B30B1/14

Inventor 阮少锋

Owner 阮建辉

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com