Anchoring method for large tonnage frp cables

A large-tonnage, anchoring technology, applied in buildings, bridge construction, bridges, etc., can solve problems such as stress concentration, long anchorage area length, and small anchorage force, so as to relieve stress concentration at the loading end, relieve lateral stress concentration, and ensure The effect of synchronous job performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

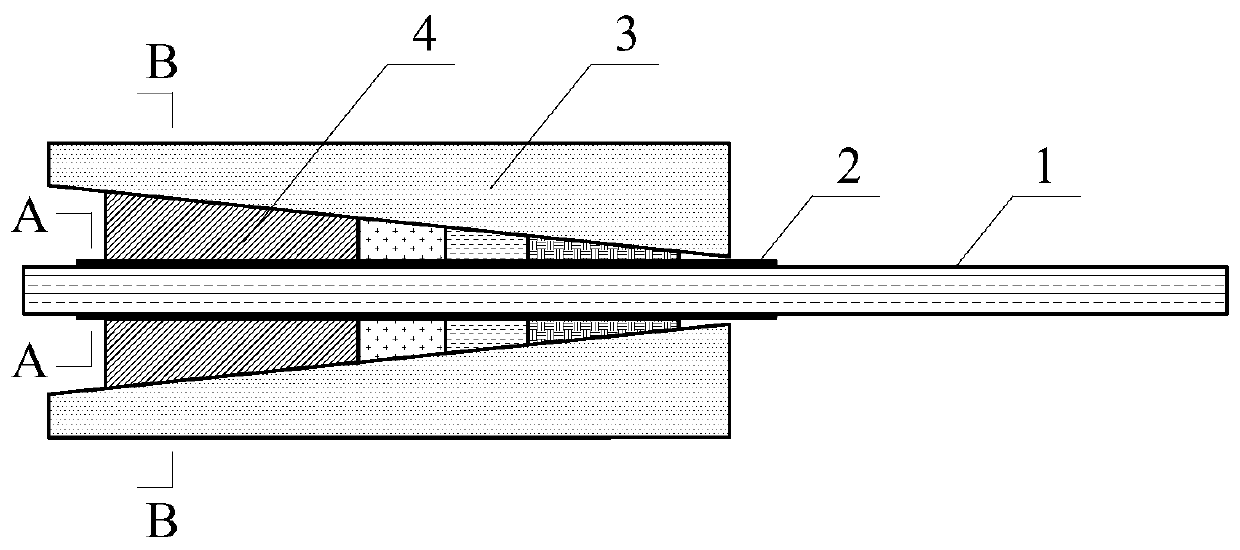

[0048] Below in conjunction with the accompanying drawings, the technical solutions of the present invention are further explained in detail. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. The modifications of all equivalent forms all fall within the scope defined by the appended claims of the present application.

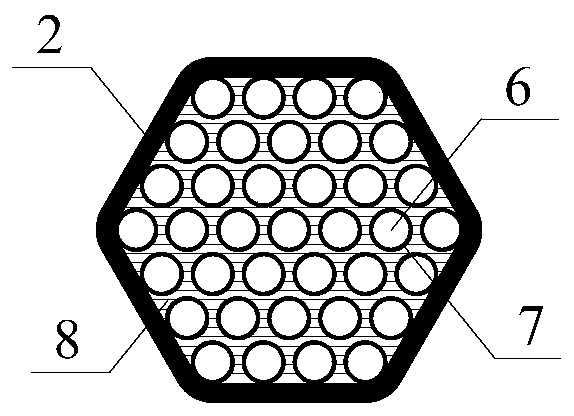

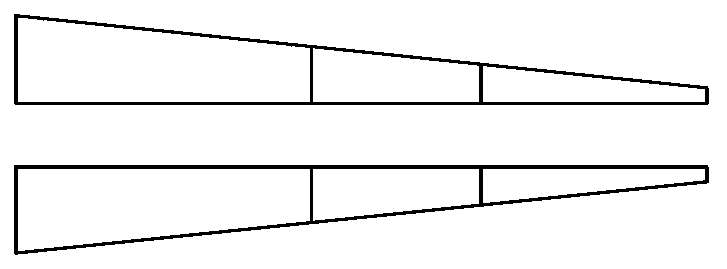

[0049] figure 2 Wrap the fiber roving 7 impregnated with resin 8 around the anchoring area of a single small-diameter FRP tendon 6 , wherein the length of the fiber roving 7 is not less than the length of the anchoring area of a single small-diameter FRP tendon 6 . The resin 8 can be epoxy resin, vinyl resin, etc., and the fiber roving 7 can be carbon fiber, basalt fiber, aramid fiber, etc. A single small-diameter FRP tendon 6 is arranged in parallel in a plane according to a certain rule to form an FRP cable 1, and a certain thickness of carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com