Forging forming process for iron ornamental part product

A technology of decorative accessories and forming technology, applied in the direction of metal processing equipment, etc., can solve the problems of increasing workshop costs, achieve the effects of reducing workshop costs, reducing heating and oxidation losses, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

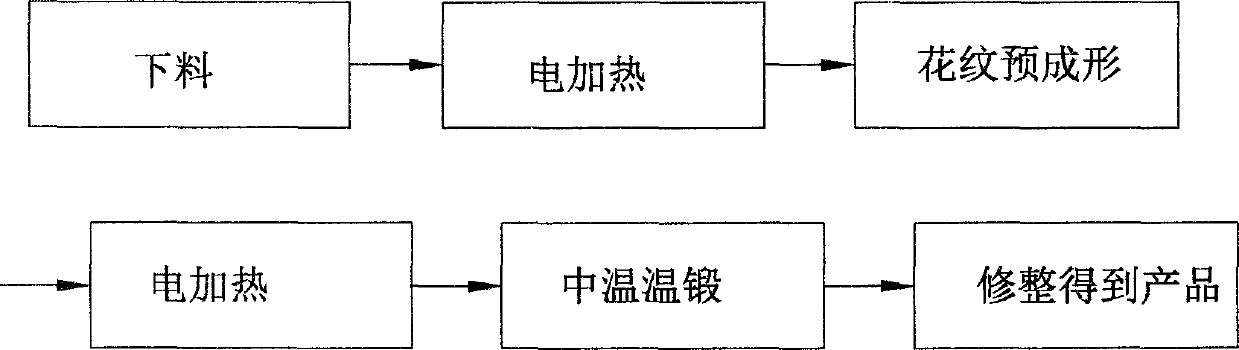

[0017] Such as figure 1 As shown, a forging and forming process of iron decorative accessories products includes the following process steps:

[0018] (1) According to the external dimensions determined by the design drawings, the material to be cut is long strip iron material or flat iron material, and air hammer equipment or press equipment is prepared at the same time;

[0019] (2) Heating the cutting parts through an electric heating furnace to below the blue brittle temperature of carbon steel at 450°C. Considering the deformation temperature rise, the heating temperature is 320°C±15°C;

[0020] (3) Using the die forging process or free forging process, use a 150KG air hammer or a 65T press to preform the pattern on the blank to obtain a blank with a pattern;

[0021] (4) Heating the cutting parts through an electric heating furnace to the range above the carbon steel blue brittle temperature of 450°C and below the recrystallization temperature of 810°C, which is 760°C±1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com