Improved fire-proof bus duct

A technology of fire-resistant bus ducts and troughs, which is applied in the field of bus ducts, can solve the problems of dampness, easy water entry and fire occurrence of busbars, and achieves the effects of good fire resistance and good insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

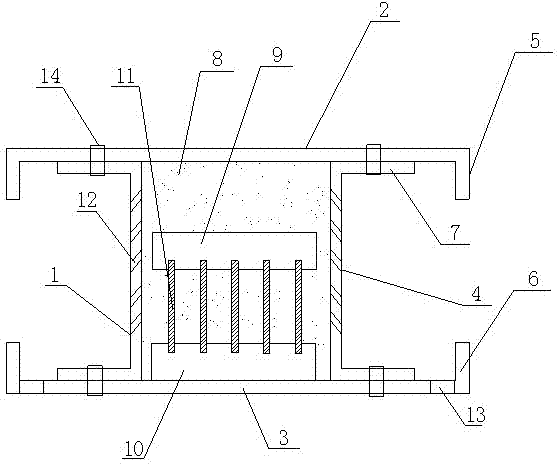

[0014] Such as figure 1 As shown, the improved refractory bus duct of the present invention includes a tank body 1, the tank body 1 is composed of an upper cover plate 2, a lower cover plate 3 and two side plates 4, and the two ends of the upper cover plate 2 are bent downwards and inwards Form the lower flange 5, the two ends of the lower cover plate 3 are bent upwards and inwards to form the upper flange 6, the lower flange 5 and the upper flange 6 can prevent rainwater from entering the tank body 1, and the two side plates 4 are bent outwards to form a horizontal The plate 7, the horizontal plate 7 of the two side plates 4, the upper cover plate 2, and the lower cover plate 3 are locked by fasteners 14, and the tank body 1 is filled with an insulator 8, the insulator 8 is mica or asbestos, and the insulation effect is good , the tank body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com