Pore wall gas flow measuring device and pore wall gas flow measuring method

A flow measurement device and gas technology, applied in the direction of volume flow measurement device, measurement device, liquid/fluid solid measurement, etc., to achieve the effect of avoiding low index outstanding accidents and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

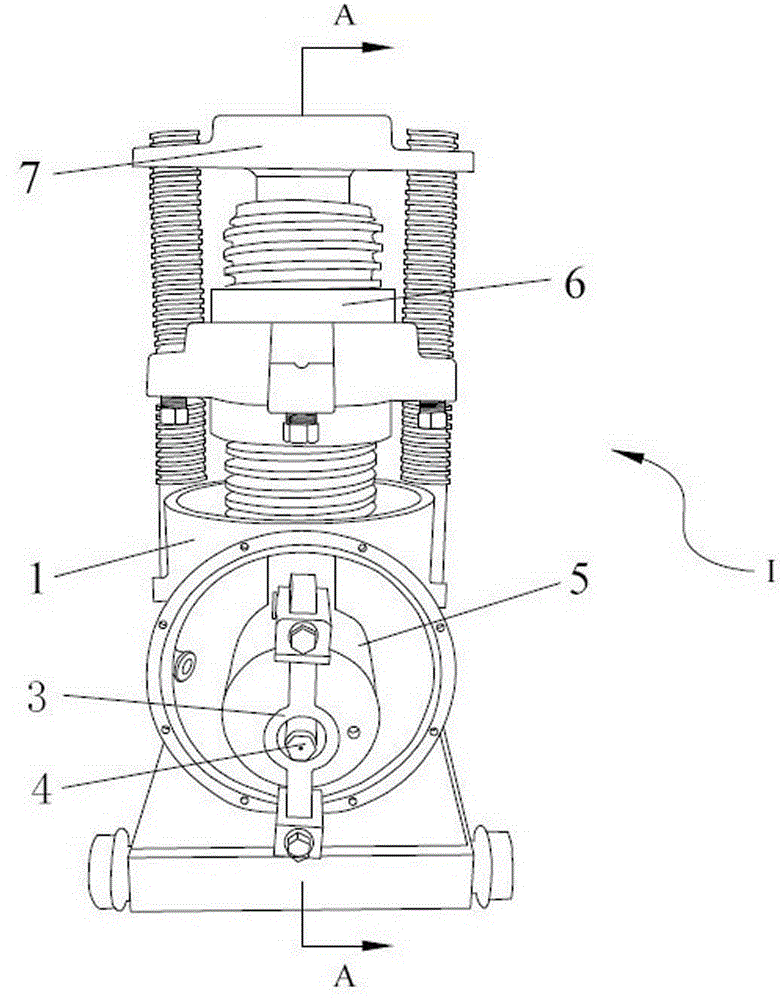

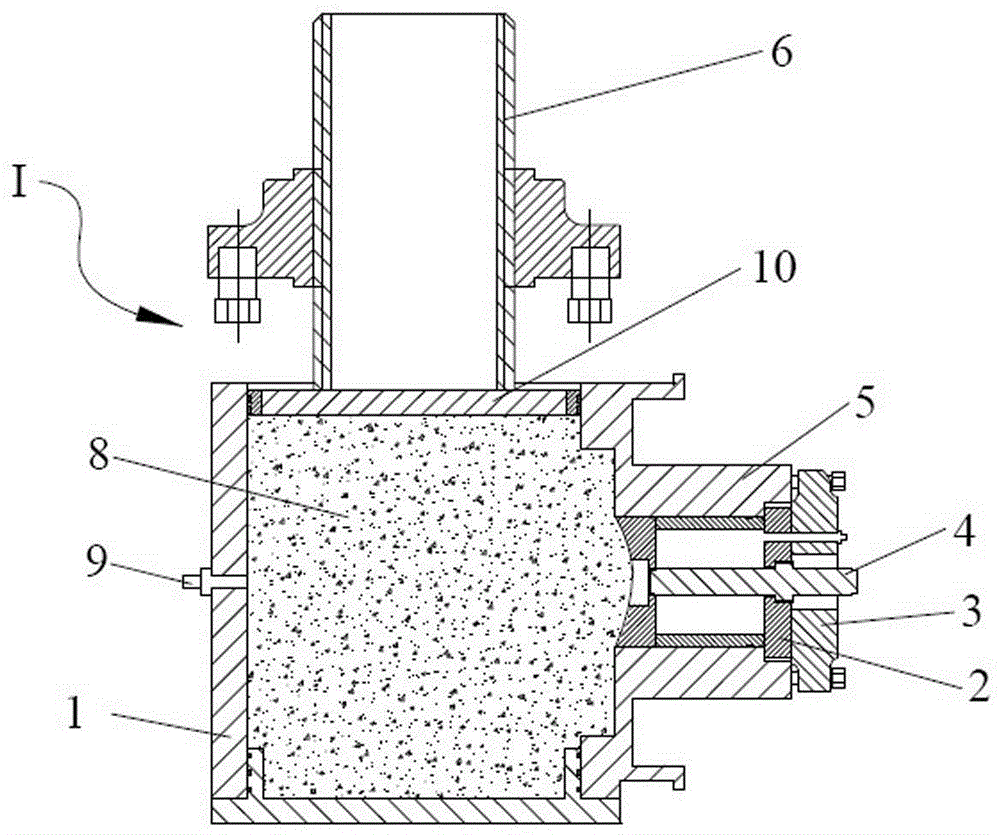

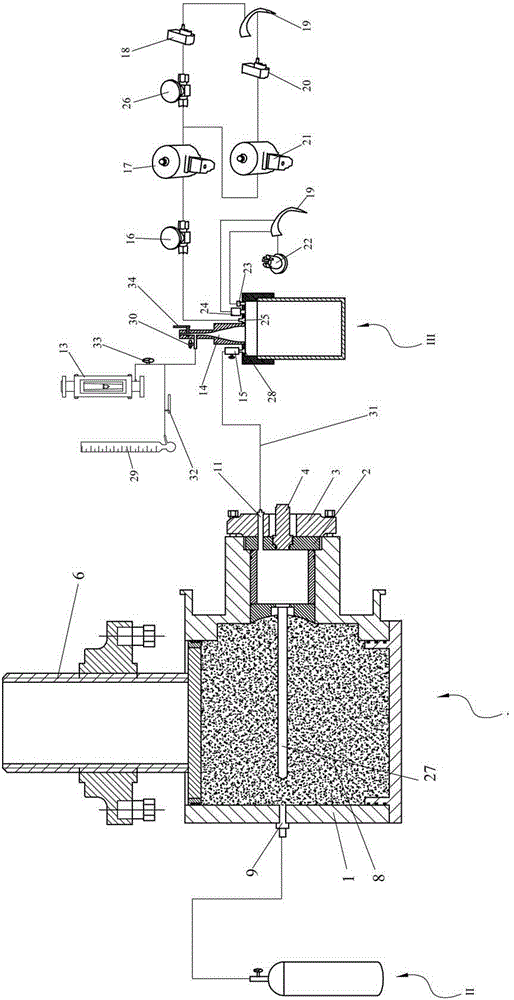

[0041] Example: see figure 1 —— Figure 13 .

[0042] A hole wall gas flow measurement device, including a coal seam simulation device I, figure 1 , figure 2 The structure of the coal seam simulation device is shown, and a drilling rig and a drill pipe are used to drill holes in the simulated coal seam 8 in the coal seam simulation device I; a gas tank II and a coal sample tank III are also included, and the coal seam simulation device I is provided with Inflatable port 9 and gas outlet 11, the coal sample tank III is provided with an air inlet 28, and the gas tank II is inflated to the coal seam simulation device I through the gas charging port 9, and the gas outlet 11 of the coal seam simulation device I is closed by a high-pressure rubber hose 31. It communicates with the air inlet 28 of the coal sample tank, and the top of the coal sample tank III is provided with a spout 14 with a valve, and the coal sample tank III is connected with a flow collection system.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com