Structure for continuous transformation of existing simply supported hollow slab girder bridge and construction method of structure

A construction method and technology of hollow slabs, which are applied in bridges, bridge parts, bridge maintenance, etc., can solve the problems of low tensile strength of filling materials, small continuous space in joint areas, and large loss of prestress, so as to achieve good anti-seismic effect and overall Good performance, simple and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

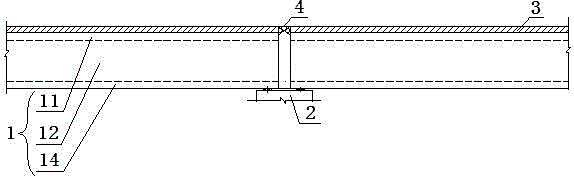

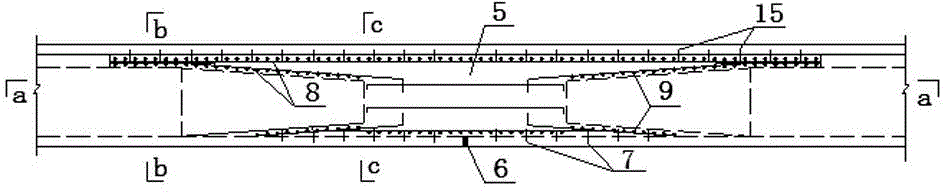

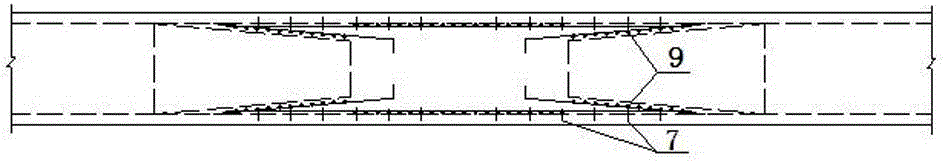

[0031] Such as Figure 1~9 As shown, a structure for the continuous reconstruction of an existing simply supported hollow slab girder bridge includes the hollow slab 1 and the pier 2 of the existing simply supported hollow slab girder bridge, and the two adjacent hollow slabs 1 on the top of the pier 2 are respectively Cut off part of the top plate 11 and part of the web 12 along the bridge direction, and form a Y-shaped joint 5 between the ends of the two hollow plates 1 after the chisel, and the Y-shaped joint 5 is equipped with steel bars and poured concrete to form The continuous section 10 of two hollow slabs 1 is connected, and the bridge deck pavement 3 is recast on the two hollow slabs 1 and the continuous section 10 .

[0032] In this embodiment, the chiseled length between the top plates 11 of the two hollow plates 1 is m, and the value of m is the range where there is a negative bending moment at the top of the continuous rear pier 2 . The chisel height of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com