Method for producing vanadium pentoxide by-product manganese sulfate by combining stone coal vanadium ore and pyrolusite

A technology for vanadium pentoxide and stone coal vanadium is applied in the field of jointly producing vanadium pentoxide by-product manganese sulfate from stone coal vanadium ore and pyrolusite, and can solve the problem of large pollution of vanadium extraction from stone coal, low metal recovery rate, vanadium problems such as low leaching rate, to achieve the effect of strengthening promotion and application value, improving metal recovery rate and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

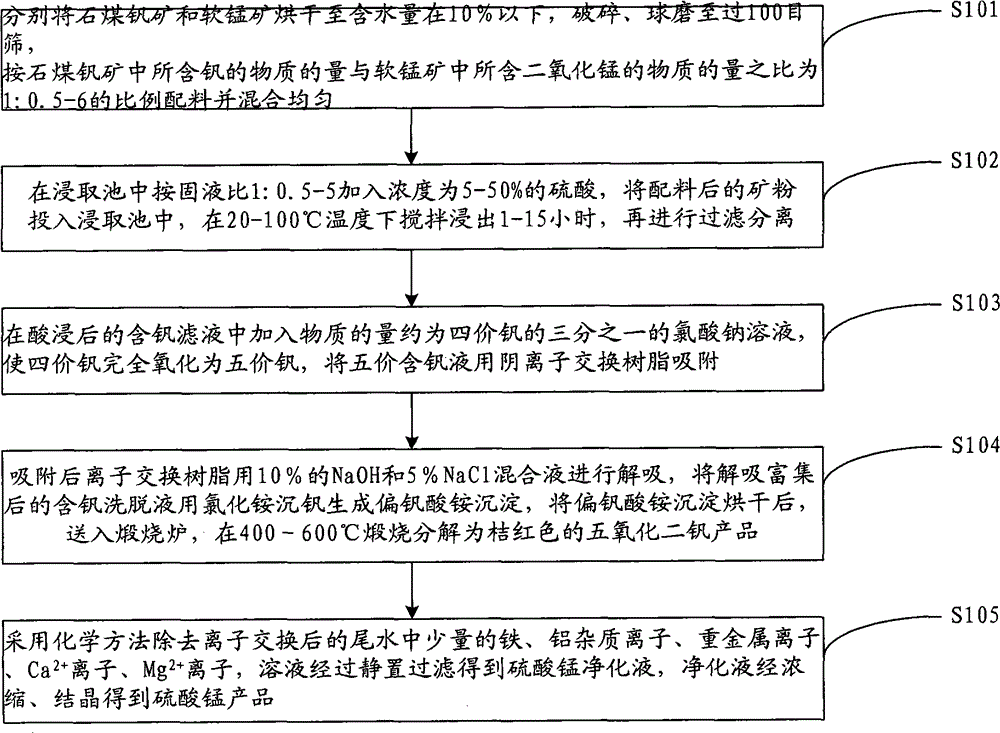

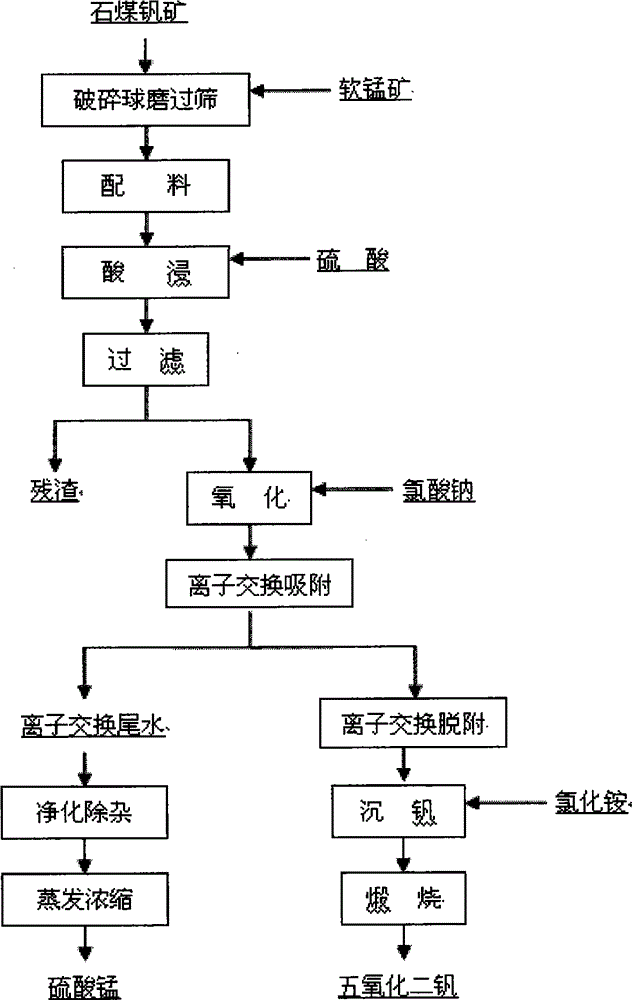

Method used

Image

Examples

Embodiment 1

[0022] According to the above-mentioned crushing ball mill sieving, batching, acid leaching, oxidation, ion exchange adsorption, ion exchange desorption, vanadium precipitation, calcination, ion exchange tail water purification and impurity removal, evaporation and concentration, etc., the steps are sequentially operated. Stone coal with a vanadium-containing grade of 1.0% is used as raw material, and the ratio of the amount of vanadium contained in the stone coal vanadium ore to the amount of manganese dioxide contained in the pyrolusite is 1:1. The leaching rate of vanadium in coal is 95%, the recovery rate of vanadium is 86%, the leaching rate of manganese in pyrolusite is 98%, and the total recovery rate of manganese is 91%.

Embodiment 2

[0024] According to the above-mentioned crushing ball mill sieving, batching, acid leaching, oxidation, ion exchange adsorption, ion exchange desorption, vanadium precipitation, calcination, ion exchange tail water purification and impurity removal, evaporation and concentration, etc., the steps are sequentially operated. Stone coal with a vanadium-containing grade of 1.5% is used as raw material, and the ratio of the amount of vanadium contained in the stone coal vanadium ore to the amount of manganese dioxide contained in the pyrolusite is 1:1. The leaching rate of vanadium in coal is 96%, the recovery rate of vanadium is 87%, the leaching rate of manganese in pyrolusite is 97%, and the total recovery rate of manganese is 90%.

Embodiment 3

[0026] According to the above-mentioned crushing ball mill sieving, batching, acid leaching, oxidation, ion exchange adsorption, ion exchange desorption, vanadium precipitation, calcination, ion exchange tail water purification and impurity removal, evaporation and concentration, etc., the steps are sequentially operated. Stone coal with a vanadium-containing grade of 1.0% is used as raw material, and the ratio of the amount of vanadium contained in the stone coal vanadium ore to the amount of manganese dioxide contained in the pyrolusite is 1:2. The leaching rate of vanadium in coal is 98%, the recovery rate of vanadium is 89%, the leaching rate of manganese in pyrolusite is 96%, and the total recovery rate of manganese is 88%.

[0027] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com