Method for preparing phenol compound and clean fuel oil from coal tar

A technology of phenolic compounds and coal tar, applied in the fields of energy technology and environmental protection, can solve the problems of serious environmental pollution, low yield of gasoline and diesel, and low added value, so as to reduce gum content, increase conversion rate, and prolong life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: high temperature coal tar is divided into light oil (o C) and heavy oil (>400 o C). The following table 1 sees the atmospheric distillation mass balance test results

[0023] The following table 2 distillate oil properties before and after atmospheric distillation.

Embodiment 2

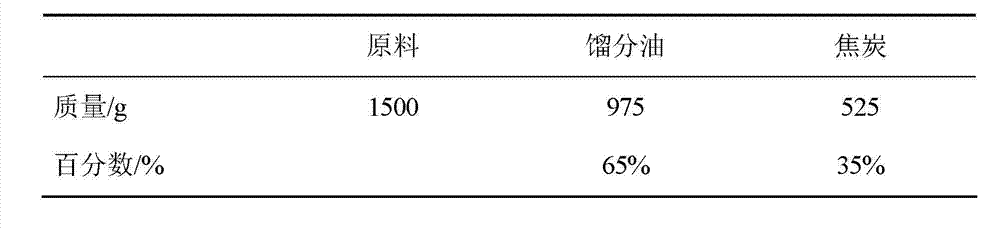

[0024] Embodiment 2: heavy oil (>400 o C) Distillate oil is obtained after delayed coking. See Table 3 below for delayed coking material balance test results

[0025]

Embodiment 3

[0026] Embodiment 3: light oil (o C) Alkaline washing and filtering to obtain basic phenate and light oil after dephenolization, the basic phenate is steamed in a steaming kettle to obtain net phenate, and then decomposed with dilute sulfuric acid to obtain crude phenol or use continuous CO 2 Decomposition process, crude phenol and sodium carbonate are obtained respectively in the decomposition tower. See Table 4 below for delayed coking material balance test results

[0027]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com