Preparation method of bamboo powder/white carbon black composite reinforced starch-based degradable plastic

A technology for degrading plastics and white carbon black, which is applied in the field of degradable material preparation, can solve the problems that the bamboo powder/silica composite reinforcing starch base has not been found, and the preparation method of degradable plastics has been reported, and achieves a rapid degradation rate , broaden the use, the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

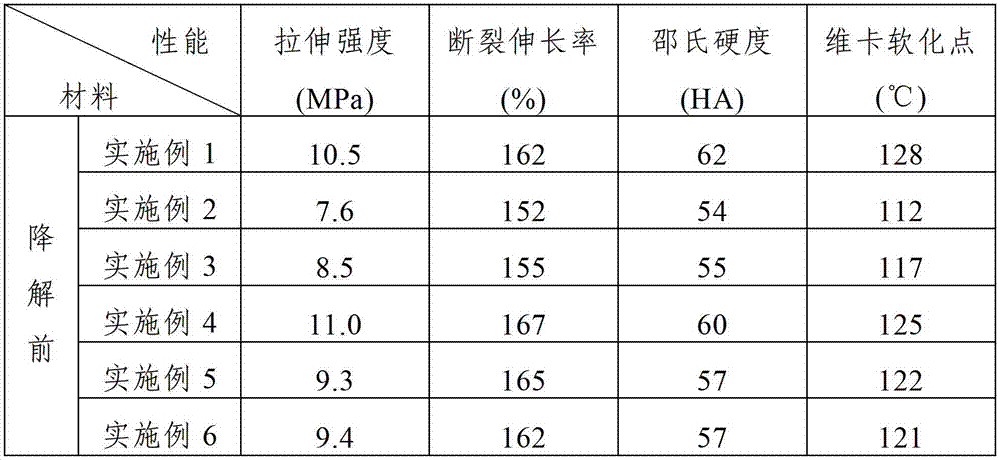

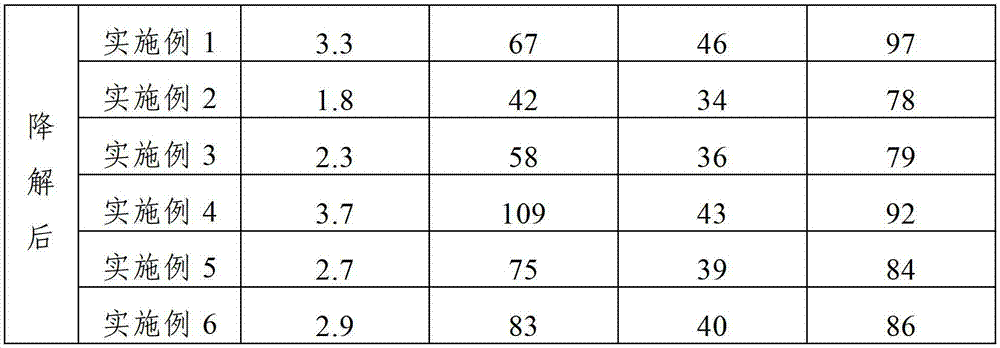

Examples

Embodiment 1

[0021] The preparation method of present embodiment bamboo powder / white carbon black composite reinforcement starch-based degradable plastic comprises the following steps:

[0022] Step 1, take the following various raw materials by weight: 40 parts of starch, 15 parts of bamboo powder, 6 parts of white carbon black, 8 parts of polyvinyl alcohol, 6 parts of plasticizer, 1.2 parts of composite auxiliary agent, 4 parts of water; The compounding aid is prepared by mixing polyethylene wax, stearic acid, white oil and a coupling agent in a mass ratio of 30:30:30:10; the plasticizer is a trihydric alcohol, preferably a trihydric alcohol It is glycerol; the coupling agent is a silane coupling agent, and the preferred silane coupling agent is the silane coupling agent KH-550 (the chemical name is 3-aminopropyltriethoxysilane);

[0023] Step 2, adding the starch, bamboo powder, white carbon black, polyvinyl alcohol, plasticizer, composite auxiliary agent and water weighed in the step 1...

Embodiment 2

[0027] The preparation method of present embodiment bamboo powder / white carbon black composite reinforcement starch-based degradable plastic comprises the following steps:

[0028] Step 1, take the following various raw materials by weight: 50 parts of starch, 10 parts of bamboo powder, 5 parts of white carbon black, 5 parts of polyvinyl alcohol, 5 parts of plasticizer, 1 part of composite auxiliary agent, and 3 parts of water; The compound auxiliary agent is prepared by mixing polyethylene wax, stearic acid, white oil and coupling agent in a mass ratio of 28:32:27:12; the plasticizer is a trihydric alcohol, preferably a trihydric alcohol It is glycerol; the coupling agent is a silane coupling agent, and the preferred silane coupling agent is the silane coupling agent KH-570 (the chemical name is 3-methacryloxypropyltrimethoxysilane);

[0029] Step 2, adding the starch, bamboo powder, white carbon black, polyvinyl alcohol, plasticizer, composite auxiliary agent and water weigh...

Embodiment 3

[0033] The preparation method of present embodiment bamboo powder / white carbon black composite reinforcement starch-based degradable plastic comprises the following steps:

[0034] Step 1, take the following various raw materials by weight: 60 parts of starch, 12 parts of bamboo powder, 9 parts of white carbon black, 6 parts of polyvinyl alcohol, 6 parts of plasticizer, 2 parts of compound auxiliary agent, 6 parts of water; The compounding aid is prepared by mixing polyethylene wax, stearic acid, white oil and coupling agent in a mass ratio of 30:28:32:8; the plasticizer is a glycol, preferably a glycol It is ethylene glycol; the coupling agent is a silane coupling agent, and the preferred silane coupling agent is the silane coupling agent YDH-151 (the chemical name is vinyltriethoxysilane);

[0035] Step 2, adding the starch, bamboo powder, white carbon black, polyvinyl alcohol, plasticizer, composite auxiliary agent and water weighed in the step 1 into a mixer and mixing uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com