Method for synthesizing block HTPE copolymer

A copolymer and block type technology, applied in the direction of adhesive types, polyether adhesives, adhesives, etc., to achieve the effect of low temperature, simple and easy method, and easy engineering enlargement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

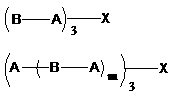

Image

Examples

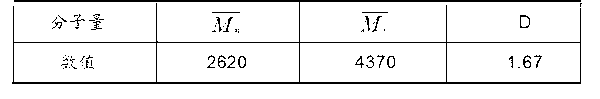

Embodiment 1

[0036] (1) Add 200g (0.3mol) of PTMEG650 and 120g (0.3mol) ) of PEG400, blow nitrogen and stir, keep the nitrogen flow at 0.1Mpa, stir for 1 hour, add dropwise a mixture of 5g (0.05mol) of concentrated sulfuric acid with a concentration of 96% and 10g of tetrahydrofuran, after the addition, the reaction temperature is raised to 110°C, and divided Moisture begins to appear in the water tank, raise the temperature to 135°C for 4 hours, continue to maintain nitrogen protection, collect 35ml of tetrahydrofuran fraction in the water separator, slowly add 300ml of distilled water as a chain terminator to quench the reaction, and keep the hydrolysis reaction at 100°C until the water is separated After 50ml of water was collected by the device, the reaction was stopped.

[0037] (2) Add water 1 to 10 times the volume of the metered distillate in step (1) as a chain terminator, hydrolyze at 100°C, and the reaction is quenched;

[0038] Pour the reaction solution into a 500ml beaker, a...

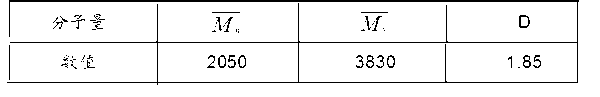

Embodiment 2

[0051] Add 200g (0.3mol) of PTMEG650 and 120g (0.3mol) of PEG400 into a 1000ml four-necked round-bottomed reaction flask equipped with a reflux condenser (with bubbler, water separator), stirrer, thermometer, and airway , pass nitrogen and stir, keep the nitrogen flow at 0.1Mpa, after stirring for 1h, add dropwise a mixture of 5g (0.05mol) concentrated sulfuric acid with a concentration of 96% and 14.2g distilled water, after the addition, the reaction temperature rises to 115°C, and continue to maintain nitrogen Protection, there is moisture in the water separator, raise the temperature to 135°C for 4 hours, collect 30ml of tetrahydrofuran fraction in the water separator, slowly add 300ml of distilled water dropwise to quench the reaction, keep the hydrolysis reaction at 100°C, until the water separator collects 50ml of water, Stop responding.

[0052] Pour the reaction solution into a 500ml beaker, add 3.6gCa(OH) 2 After fully stirring, add 300ml tetrahydrofuran (anhydrous)...

Embodiment 3

[0057] Add 200g (0.3mol) of PTMEG650 and 60g (0.3mol) of PEG200 into a 1000ml four-necked round-bottomed reaction flask equipped with a DC condenser (equipped with a vacuum tailpiece and a receiving bottle), a stirrer, a thermometer, and an airway, After stirring for 1 hour, add 5 g (0.05 mol) of a mixture of concentrated sulfuric acid with a concentration of 96% and 10 g of tetrahydrofuran dropwise. After the addition, stop the nitrogen flow. The reaction pressure is reduced to 10 mmHg and the temperature is raised to 120 ° C. React for 3 hours. Collect water and 30ml of tetrahydrofuran fraction in the receiving bottle; after enough fractions are collected, stop the decompression, protect with nitrogen, slowly add 300ml of distilled water dropwise to quench the reaction, and keep the hydrolysis reaction at 100°C until the water separator collects 50ml of water, then stop the reaction.

[0058] Pour the reaction solution into a 500ml beaker, add 3.6gCa(OH) 2 After fully stirri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com