Shape-controlled mesoporous silica nano-material and preparation method thereof

A nanomaterial and mesoporous silicon technology, applied in the field of mesoporous silicon nanomaterials and their preparation, can solve the problems of small specific surface area and pore volume, porous silicon without regular morphology, disordered pore structure, etc., and achieve high pore volume. , the effect of controllable morphology and ordered pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

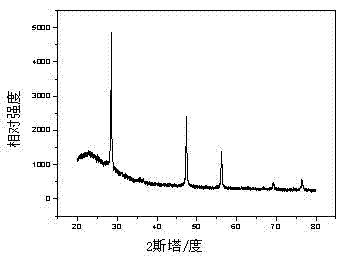

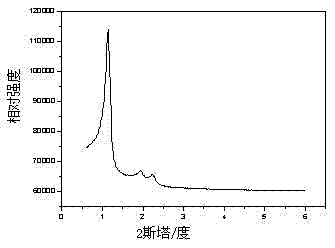

[0043] A method for preparing a shape-controllable mesoporous silicon nanomaterial, specifically comprising the following steps:

[0044] First, using mesoporous silica micronanoparticles as the precursor, using magnesium powder as the reducing agent, calculated according to the molar ratio, that is, the ratio of mesoporous silica micronanoparticles:magnesium powder is 1:0.1, that is, 6.0g Mesoporous silica micro-nano particles and 2.4g of magnesium powder are mixed evenly in a stainless steel reactor;

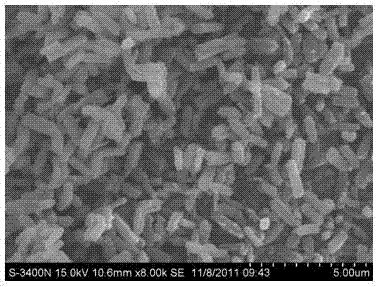

[0045] The shape of the mesoporous silica micro-nano particles used is rod-like;

[0046] The mesoporous silica micro-nanoparticles used above are prepared by the following methods:

[0047] Weigh 1.8 grams of P123 (the P123 is a triblock copolymer Pluronic P123 (Sigma-Aldrich Company)), add 80mL of 2M HCl and 3 grams of potassium chloride respectively, stir at 38°C for 1.5h, and wait until the P123 is completely dissolved. Add 2.0 grams of tetraethyl orthosilicate (TEOS), s...

Embodiment 2

[0060] A method for preparing a shape-controllable mesoporous silicon nanomaterial, specifically comprising the following steps:

[0061] First, using mesoporous silica micronanoparticles as the precursor, using magnesium powder as the reducing agent, calculated according to the molar ratio, that is, the ratio of mesoporous silica micronanoparticles:magnesium powder is 1:5, that is, 0.6g Mesoporous silica micro-nano particles and 1.2g of magnesium powder are mixed evenly;

[0062] The shape of the mesoporous silica micro-nano particles used is ellipsoidal;

[0063] The ellipsoidal mesoporous silica micro-nanoparticles used above are prepared by the following methods:

[0064] Weigh 1.8g of P123, add 80mL of 2M HCl, 5.6g of potassium chloride and 2.6g of ethanol respectively, stir at 38°C for 1.5h, wait until P123 is completely dissolved, add 2.12g of TEOS, stir vigorously for 10min, keep the temperature at 38°C, and let it stand for 24h Put the obtained reactant into a 100mL...

Embodiment 3

[0073] A method for preparing a shape-controllable mesoporous silicon nanomaterial, specifically comprising the following steps:

[0074] First, using mesoporous silica micronanoparticles as the precursor, using magnesium powder as the reducing agent, according to the molar ratio calculation, that is, the ratio of mesoporous silica micronanoparticles:magnesium powder is 1:2.5 and 1.0g of mesoporous Porous silica micro-nano particles and 1.0g of magnesium powder are mixed evenly;

[0075] The shape of the mesoporous silica micro-nano particles used is rod-like;

[0076] The mesoporous silica micro-nanoparticles used above are prepared by the following methods:

[0077] Weigh 1.5 g of P123, add 100 mL of 2M HCl and 4.5 g of potassium chloride respectively, stir at 38 °C for 1.5 h, wait until P123 is completely dissolved, add 2.0 g of TEOS, stir vigorously for 10 min, keep the temperature at 38 °C, and let it stand for 24 h Put the obtained reactant into a 100mL polytetrafluoro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com